Dustproof router and working method thereof

A router and dust-proof technology, applied in the field of dust-proof routers, can solve the problems of inconvenient movement of different plates to processing parts, dust accumulation inside the device, single dust-proof structure, etc., to improve stability performance, improved quality and efficiency, and a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0037]下面将结合本发明实施例中的附图,对本发明实施例中的技术方案进行清楚、完整地描述,显然,所描述的实施例仅仅是本发明一部分实施例,而不是全部的实施例。基于本发明中的实施例,本领域普通技术人员在没有作出创造性劳动前提下所获得的所有其它实施例,都属于本发明保护的范围。

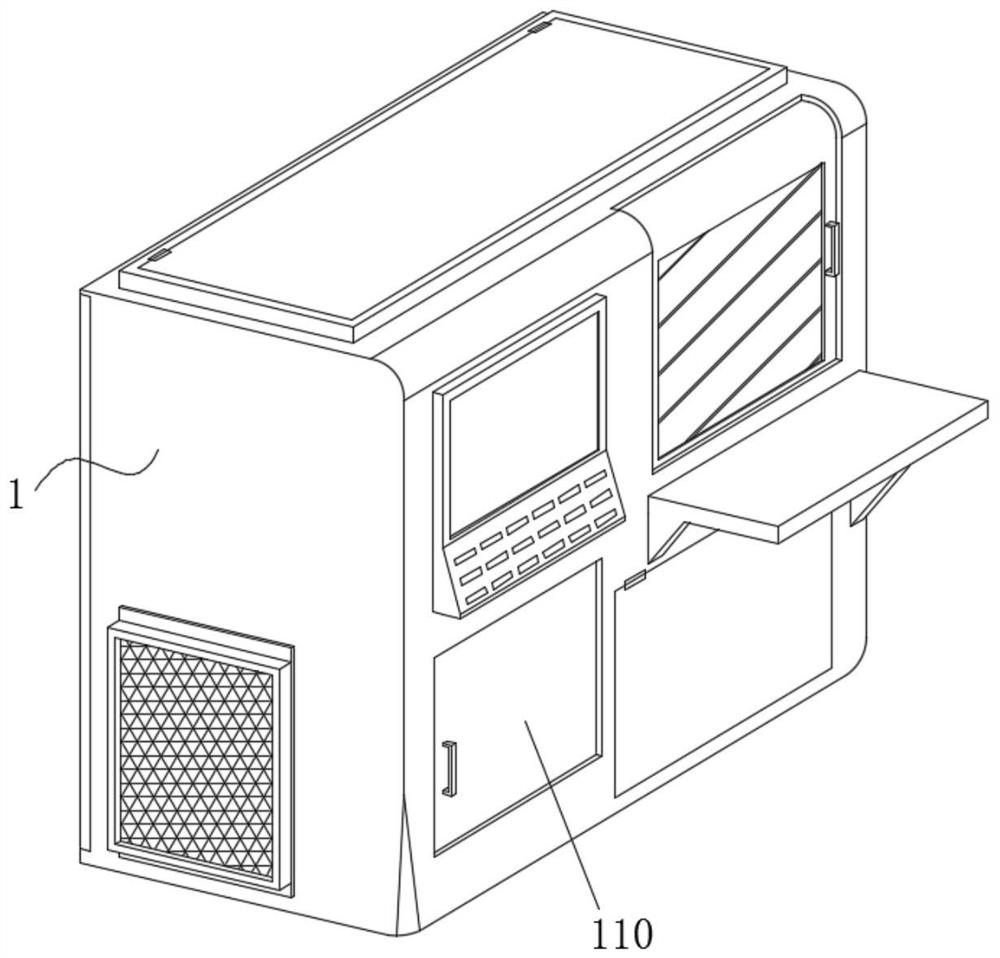

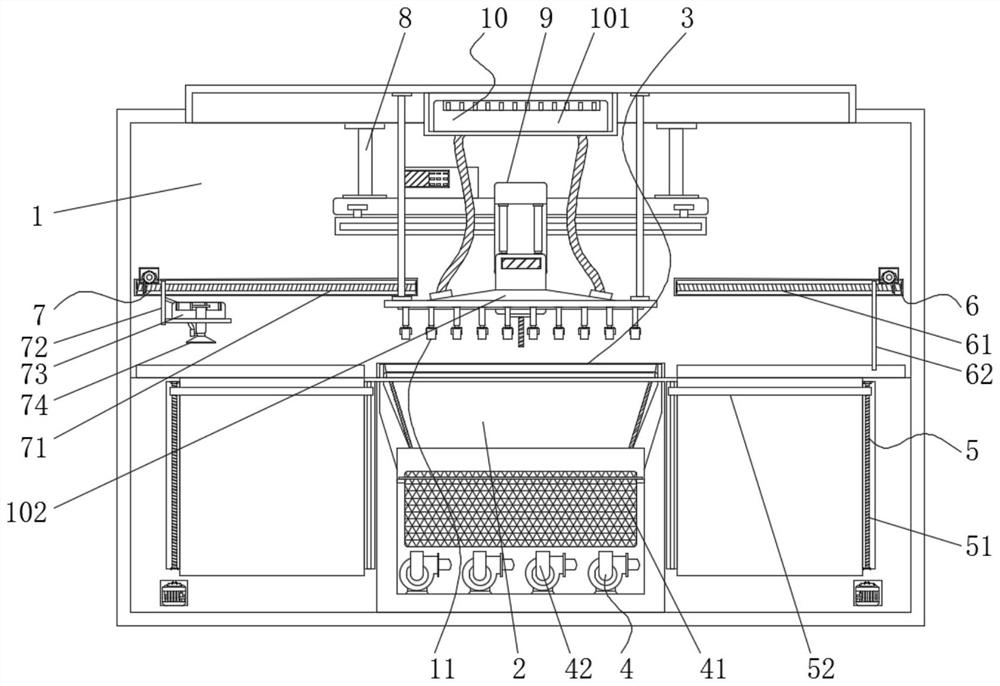

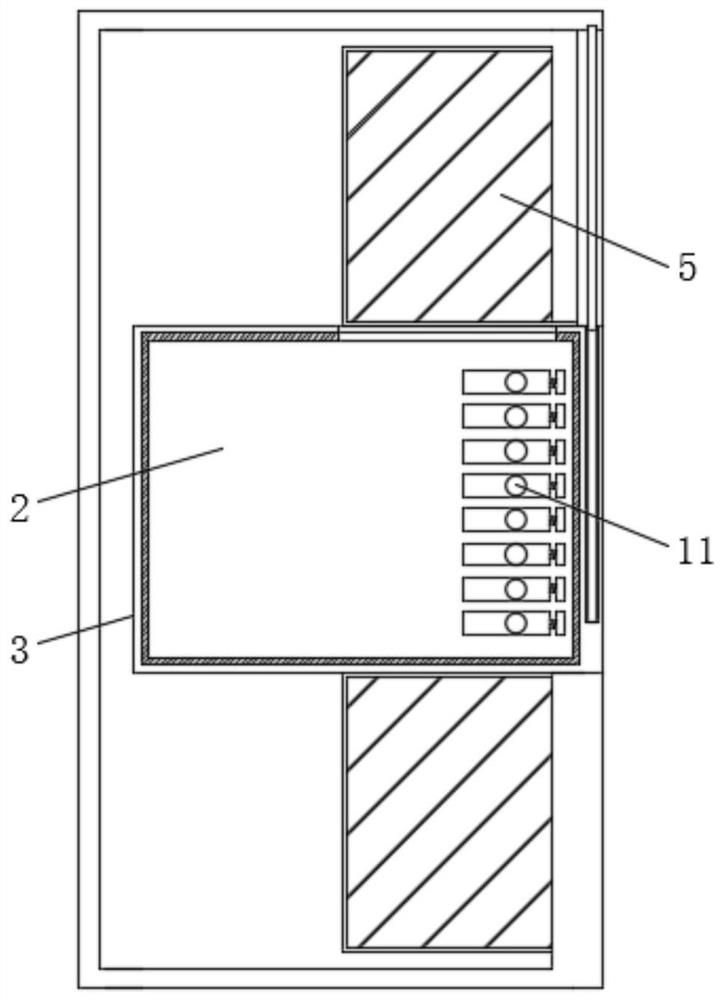

[0038]请参阅图1-图6所示,本发明为一种防尘式镂铣机,包括加工箱1,加工箱1的内部安装有加工台2,且加工箱1内部靠近加工台2的上侧安装有驱动架8,驱动架8的输出端安装有镂铣机构9,驱动架8包括X轴的驱动构件和Y轴的驱动构件,镂铣机构9包括纵向的移动结构,从而提高装置的加工范围,加工箱1内部靠近加工台2的上侧安装有若干个并排分布的定位机构11,加工箱1内部靠近加工台2的两侧均安装有抬升机构5,且加工箱1内部靠近两组抬升机构5的上侧分别安装有第一移动机构6和第二移动机构7,用于将原料在装置内部进行移动,镂铣机构9的外侧与加工箱1之间安装有鼓风机构10,用于将粉尘向下吹动,避免粉尘飘溢到空中,加工台2的上侧安装有呈矩形分布的阻隔机构3,且加工台2的内部安装有与阻隔机构3连通的抽风机构4,用于在加工台2加工区域的外侧形成空气通道,在粉尘经过时,将其进行回收。

[0039]加工箱1前表面的两侧均安装有两组侧推门110,一组侧推门110正对一组抬升机构5的一侧,在抬升机构5下降时,可以将加工后的原料从加工箱1中取出,另一组侧推门110位于另一组抬升机构5的上侧,用于将未加工的原料放置至加工箱1中。

[0040]请参阅图2-图3所示,第一移动机构6包括水平设置的第一丝杆驱动器61,第一丝杆驱动器61的输出端安装有推动板62,推动板62在未使用时,靠在加工箱1内部的一侧,即对应抬升机构5远离加工台2的一侧,从而在启动时,可以将对应抬升机构5中最上侧的原料推动至加工台2的上侧。

[0041]第二移动机构7包括水平设置的第二丝杆驱动器71,第二丝杆驱动器71的输出端安装有组装架72,组装架72的内部安装有连通的真空泵73和吸附机构74,吸附机构74的内部设置有纵向的电动伸缩结构,用于与下侧的原料进行接触。

[0042]抬升机构5包括设置在加工箱1内部的收纳槽,收纳槽内部的一侧安装有第三丝杆驱动器51,且另一侧固定连接有滑动管,第三丝杆驱动器51的输出端安装有水平设置的移动板52,移动板52远离第三丝杆驱动器51的一...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com