Assembling and welding clamp suitable for steel structure

A technology for welding jigs and steel structures, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as large space jig size, troublesome locking jig angle, difficulty in obtaining high adjustment accuracy, etc., to achieve The structure is simple and reliable, and the effect of fewer parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments.

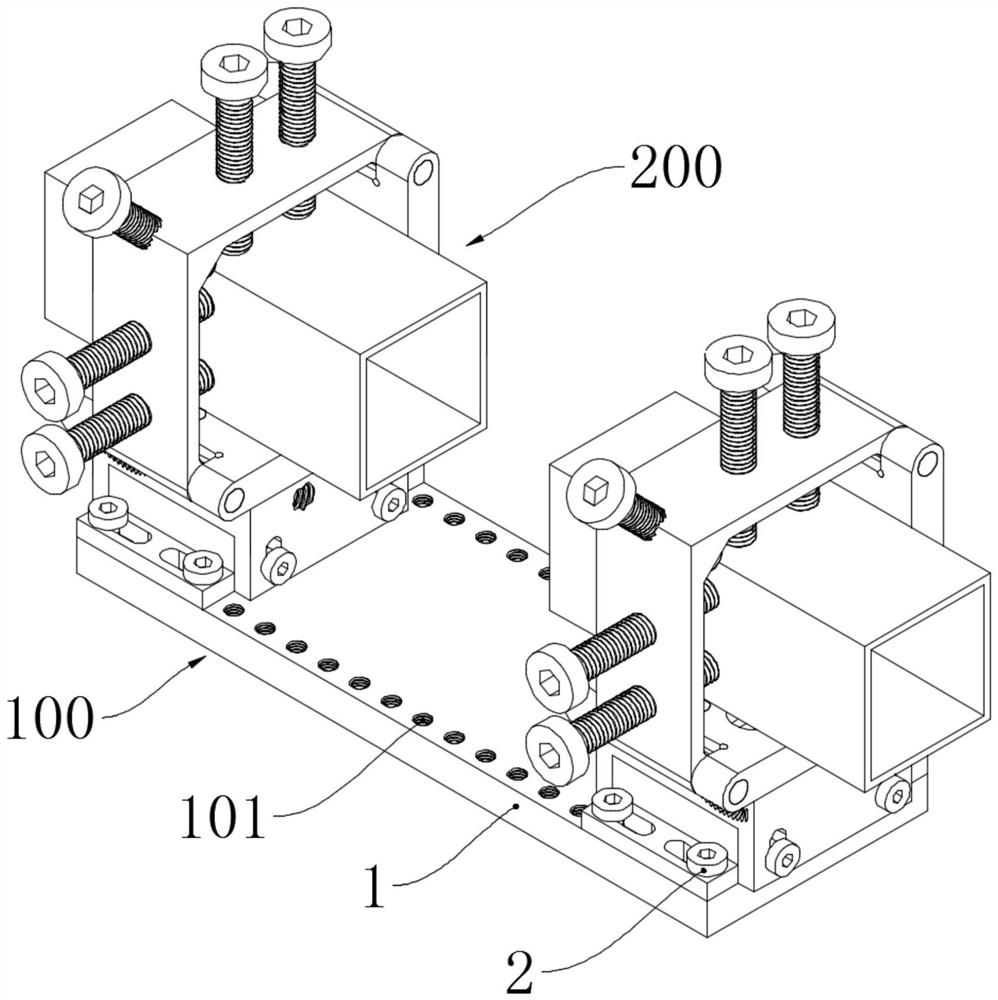

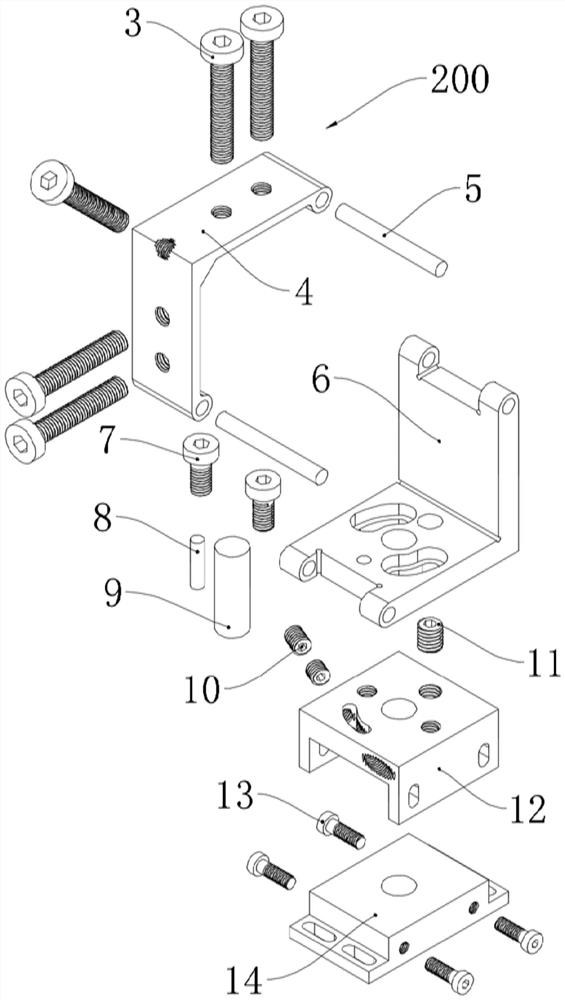

[0029] See e.g. Figure 1-Figure 2 An assembly welding fixture suitable for a steel structure shown includes a bottom assembly 100 and a top assembly 200 arranged above it. The bottom assembly 100 includes a bottom support plate 1 and a support plate screw 2 installed above it. The bottom support plate The upper surface of 1 is smoothed by a grinding machine, and the bottom plate 1 after grinding is subjected to hardening treatment on the outside. The distribution spacing corresponds to the length and distribution spacing of the table edge fixing grooves 1403. The support plate screws 2 are located inside the support plate screw holes 101,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com