Flexible power supply wiring method for thermal power plant

A wiring method and technology for factory power use, applied in electrical components, circuit devices, emergency power supply arrangements, etc., can solve the problem of high cost, reduce external power purchases, save production costs, and enrich the effect of calling methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to facilitate a better understanding of the present invention, the following examples are used to illustrate, which belong to the protection scope of the present invention, but do not limit the protection scope of the present invention.

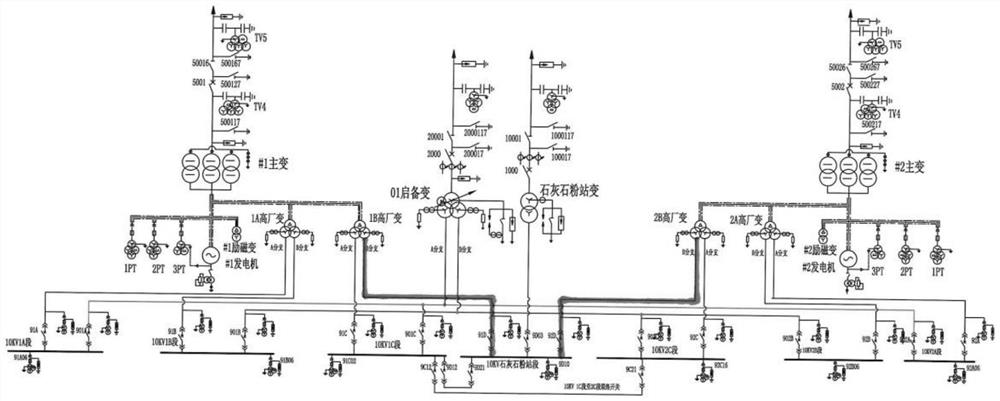

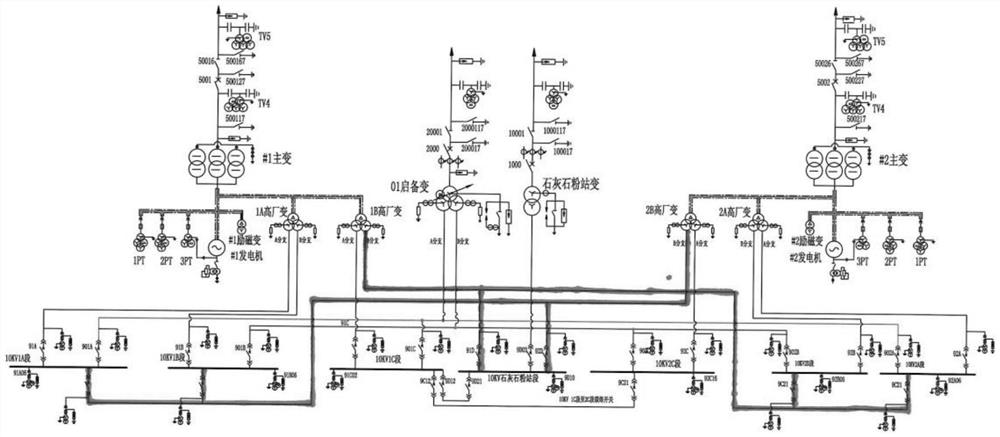

[0028] The applicant's high-voltage plant voltage is 10kV first-class, and a single unit is equipped with two high-voltage split transformers. One of the 60 / 33-33MVA high-voltage plant working split transformers has two 10kV working bus sections (A and B sections); the other 75 / 38-38MVA high-voltage public desulfurization split transformer has one branch with a 10kV public desulfurization bus. Section (C section), another branch to the 10kV limestone powder station section. The 10kV public desulfurization bus section (C section) of a single unit is connected to the 10kV public desulfurization bus section (C section) of another unit through a tie switch; the 10kV limestone powder station section is a reserved load with a reserv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com