Inclined heating type semiconductor type gas sensor testing device and method

A gas sensor and testing device technology, applied in measuring devices, sampling devices, electrical devices, etc., to reduce interference and errors, shorten wiring, and speed up shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

Detailed ways

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings.

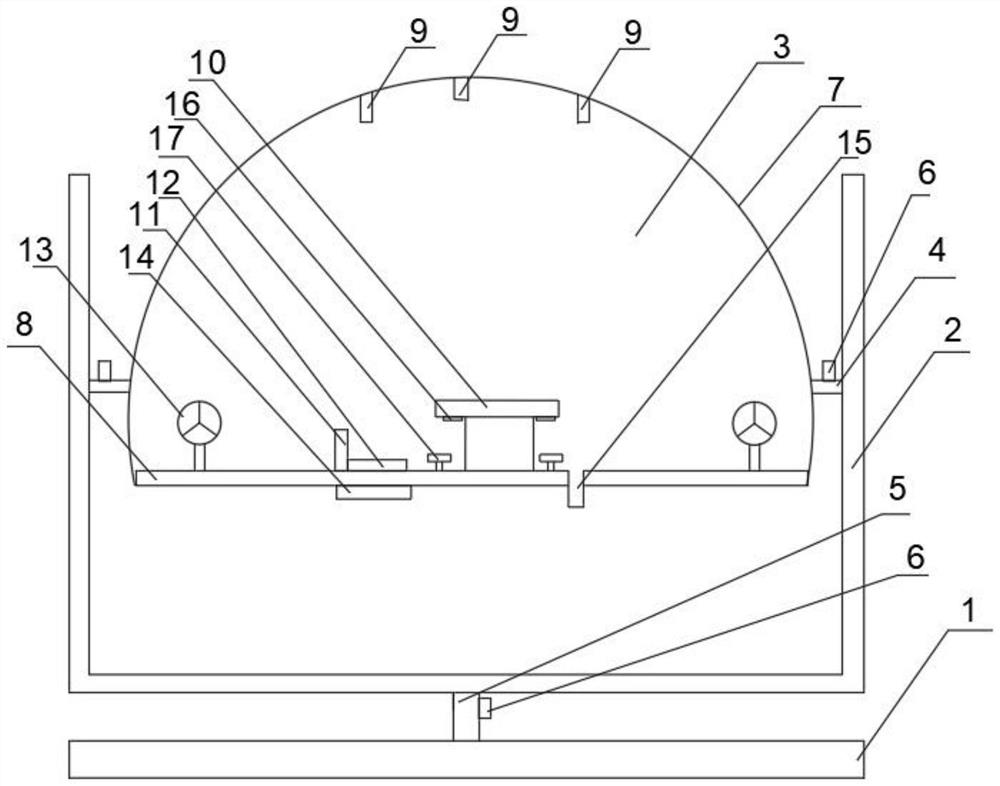

[0031] A testing device and method for a side-heating semiconductor type gas sensor, such as figure 1 As shown, it includes a base 1, a fixed frame 2 and a cavity 3, and the two sides of the cavity are connected to the fixed frame by horizontal connecting rods 4, which are used for the axial rotation of the cavity in the horizontal direction, and the fixed frame is connected vertically The direction connecting rod 5 is connected with the base in rotation, and is used to fix the frame and the cavity to rotate axially along the vertical direction. The horizontal connecting rod and the vertical connecting rod are respectively provided with top screws 6, which are respectively used to limit the axis of the cavity. Rotate to the axis of the rotating and fixed frame.

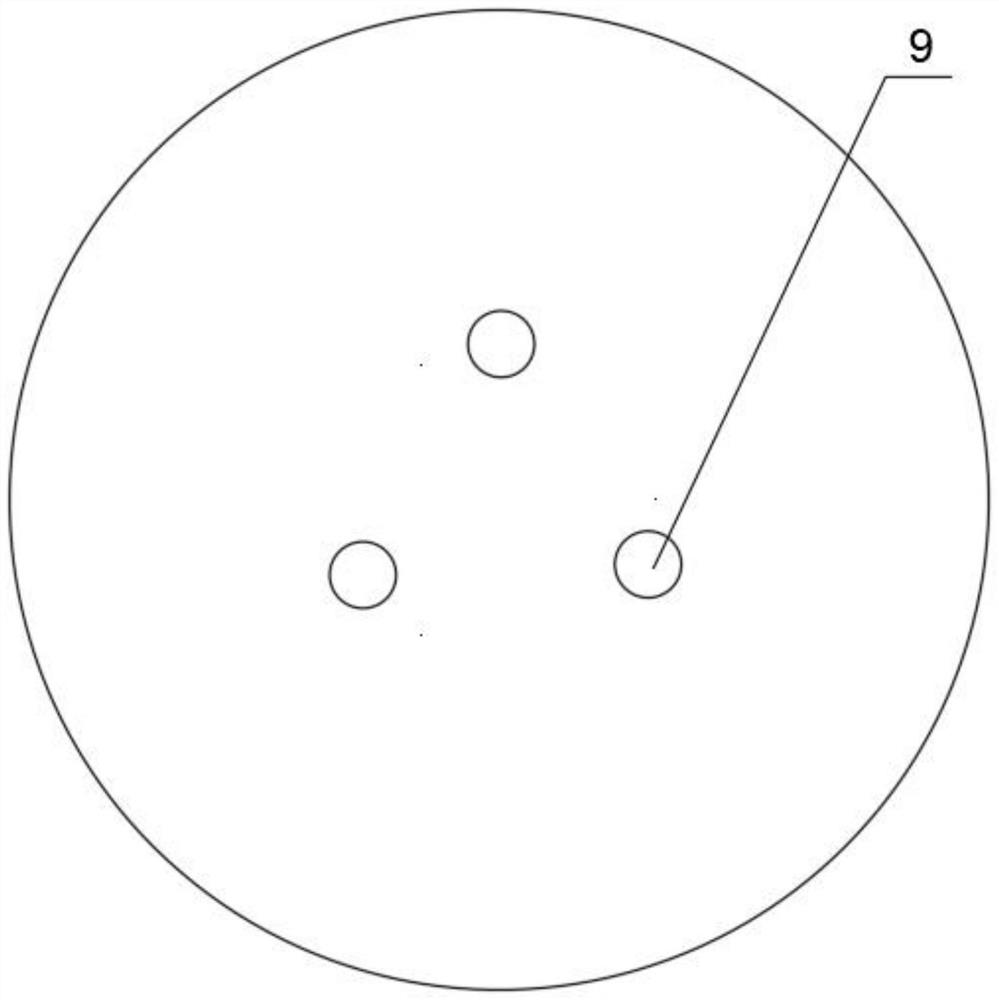

[0032] The cavity includes a spherical casing 7 and a fixed platform 8. The sphe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com