Rod clamping mechanism for efficient rod changing and wire drawing feeding device

A technology of feeding device and clamping rod, which is applied in manufacturing tools, glass manufacturing equipment, etc., to achieve the effect of reducing diameter size deviation, improving positioning accuracy, and convenient and quick operation.

Pending Publication Date: 2022-06-10

河南神玖天航新材料股份有限公司

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The object of the present invention is to provide a clamping rod mechanism for a high-efficiency rod changing wire drawing feeding device, which is used to solve the complicated and troublesome operation of the existing clamping rod mechanism, low efficiency and Technical problem of poor positioning accuracy of quartz rods

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment approach

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

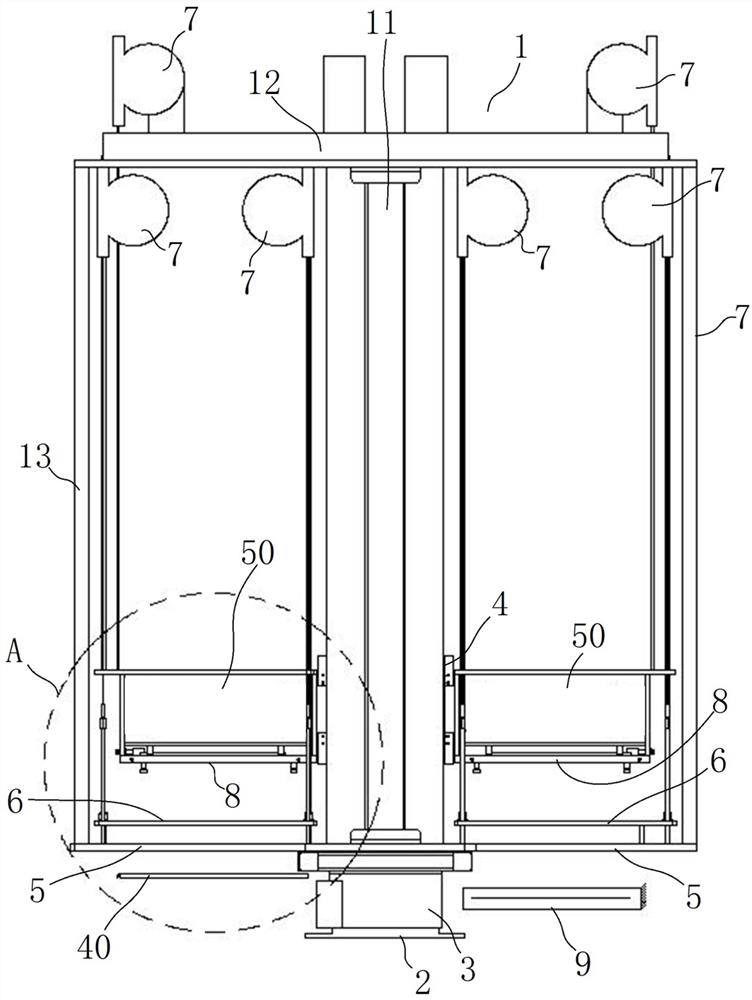

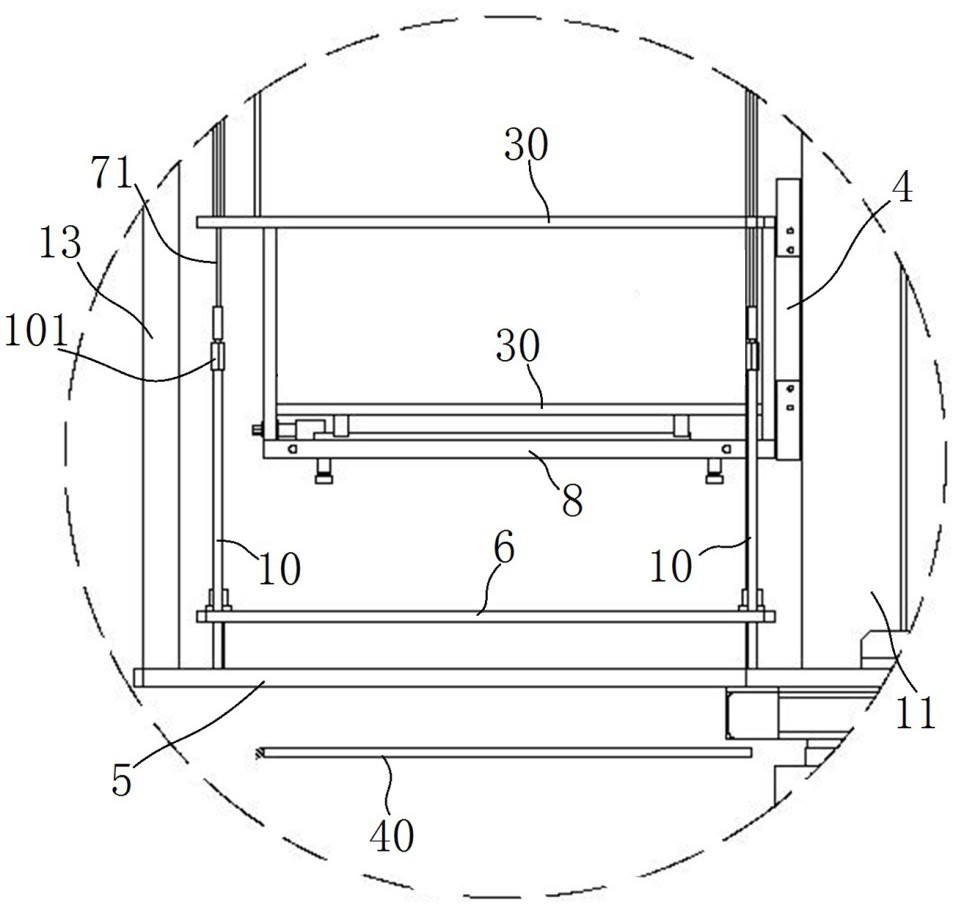

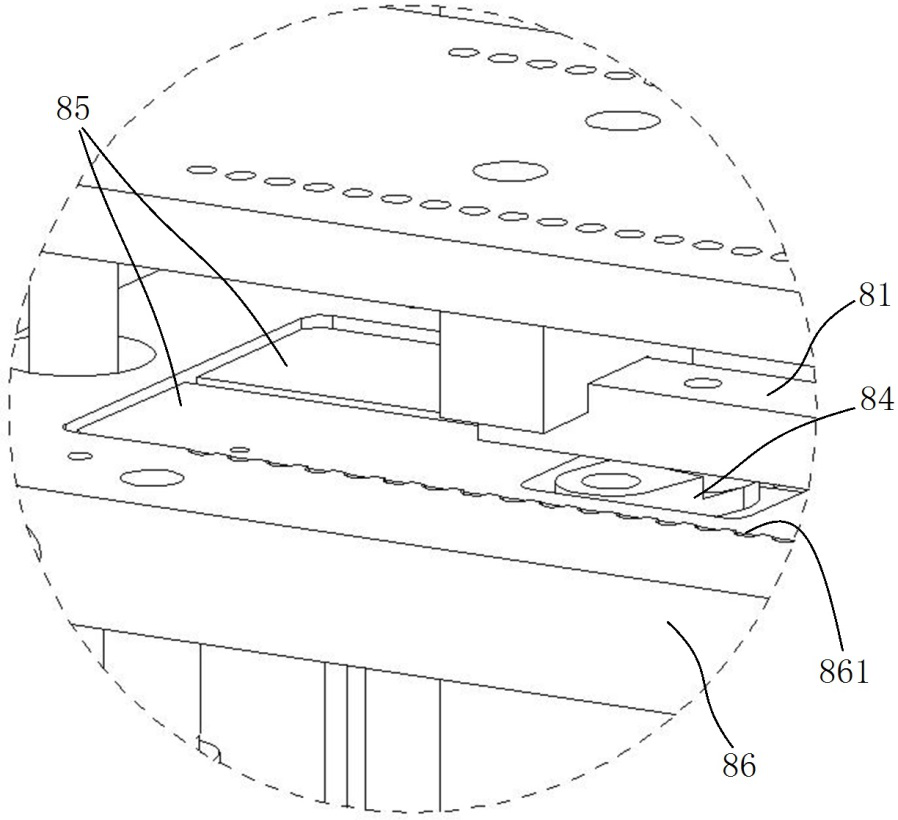

The invention relates to a rod clamping mechanism for an efficient rod changing and wire drawing feeding device. The rod clamping mechanism is used for solving the technical problems that an existing rod clamping mechanism is tedious and troublesome in operation, low in efficiency and poor in quartz rod positioning precision. The rod clamping mechanism for the efficient rod changing and wire drawing feeding device comprises a fixed clamping plate, a transverse guide rod, a movable clamping plate, a sliding rod and a driving mechanism. The sliding rod is driven by the driving mechanism to move so as to drive the at least two connecting rod groups to act, and each connecting rod group drives the two movable clamping plates to synchronously move towards the corresponding fixed clamping plates, so that the two rows of quartz rods are synchronously clamped. The quartz rod clamping device has the advantages of being convenient, fast and efficient to operate, high in quartz rod positioning precision and uniform and consistent in clamping force on all quartz rods.

Description

Technical field [0001] The present invention involves a coating mechanism for a high -efficiency switch to the feeding device. Background technique [0002] At present, the manufacturing method of quartz fiber is mainly made by the first -class drawing method. When the quartz rod is melted, the litter needs to use the device to drive multiple quartz rods through its corresponding burner to melt the quartz rods.In order to improve the efficiency, tensile quartz fiber is used to improve the efficiency. Generally, dozens to hundreds of quartz rods need to be made. Traditional sticks are tediously operated, low efficiency, unevenly clamped, and easy to clamp the stick mechanism.The poor shaking and positioning accuracy can easily lead to the position accuracy of the sandwiches that is held than the design requirements. The position deviation of the quartz rod directly affects the distance from the flame mouth, resulting in poor melting effect, unevenness, and affecting the final prod...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C03B37/025C03B37/03

CPCC03B37/025C03B37/03

Inventor 李泉涌李丽景

Owner 河南神玖天航新材料股份有限公司

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com