Marshalling station line anti-slip equipment management and control method and system

A technology for equipment control and marshalling yard, applied in the field of railway marshalling yard, to achieve the effect of high safety, reliability and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

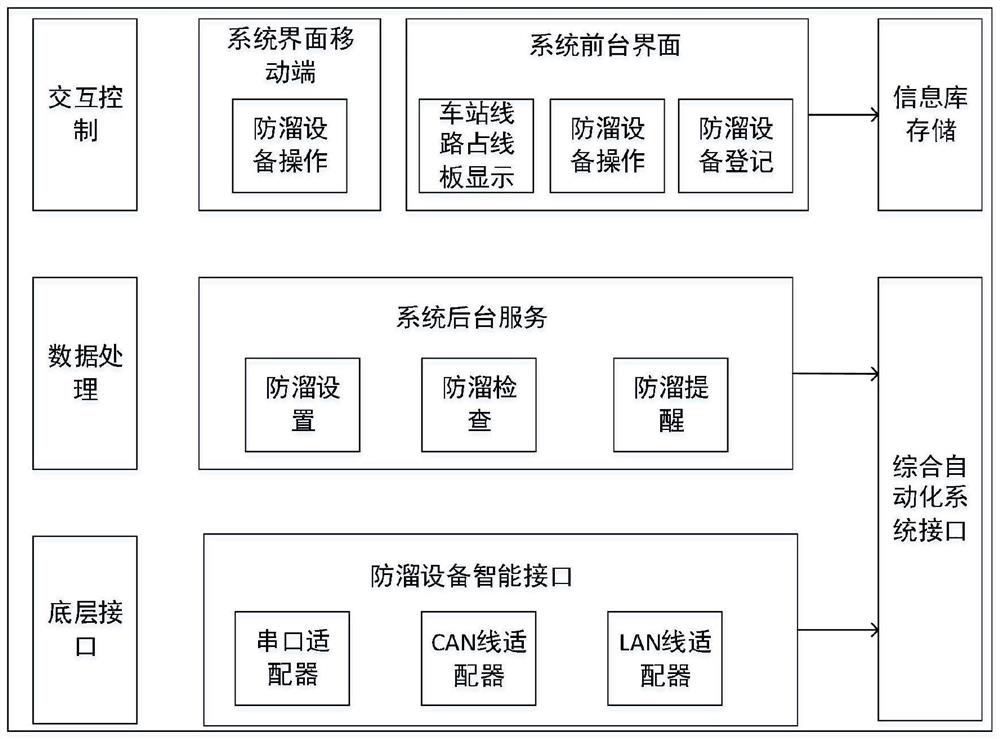

Method used

Image

Examples

Embodiment Construction

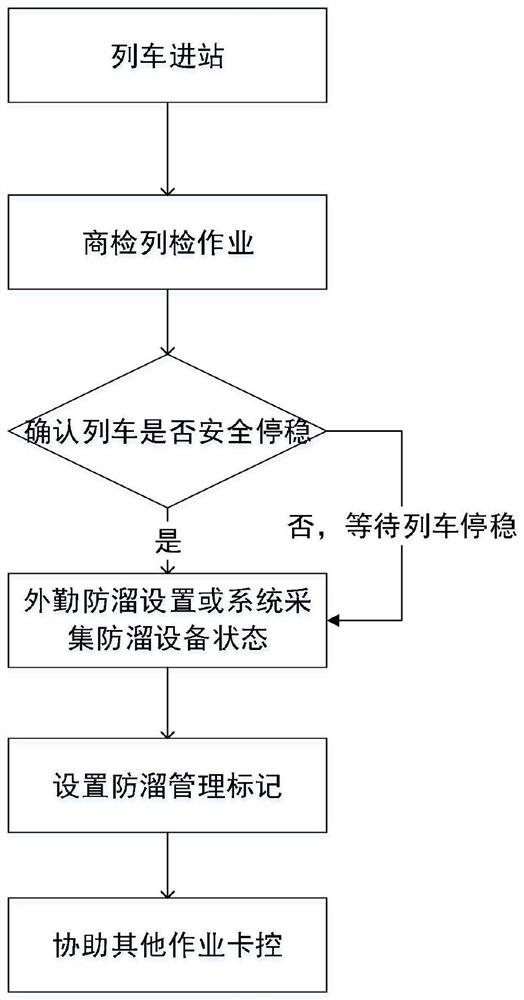

[0069] The embodiment of the present invention takes the specific execution method of the management and control system and method in the actual operation process of the marshalling station as an example.

[0072] S2: Check the situation of the on-site anti-slip equipment: the use of the anti-slip equipment passes through the station line busy board of the management and control system

[0075] S21: divide the interface display range according to the field of the actual marshalling yard;

[0086] If the train is not stopped, the anti-slip setting is not performed.

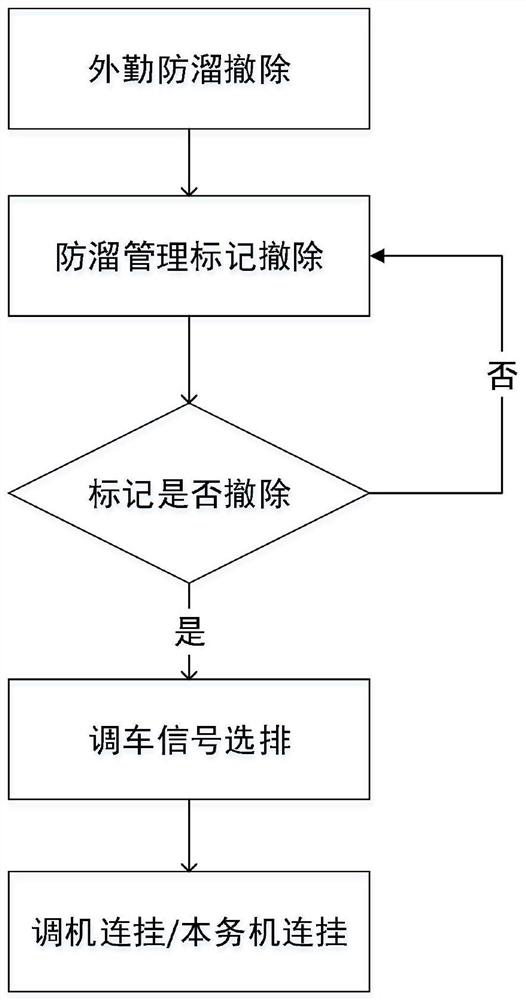

[0088] S4: when the anti-slip removal operation needs to be performed, the anti-slip removal operation is performed on the anti-slip equipment. As shown in Figure 3, the

[0089] S41: From the integrated automation system interface, collect the work plan command of the watchman or signalman, and notify the field post

[0093] The above steps do not follow a strict sequence relationship unless otherwise specified. Alth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com