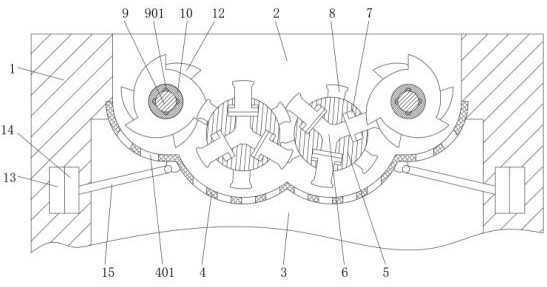

Four-shaft shredding machine for waste steel

A shredder and steel technology, applied in the direction of grain processing, etc., to achieve the effect of enhanced secondary shredding effect, enhanced extrusion force, and improved shredding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

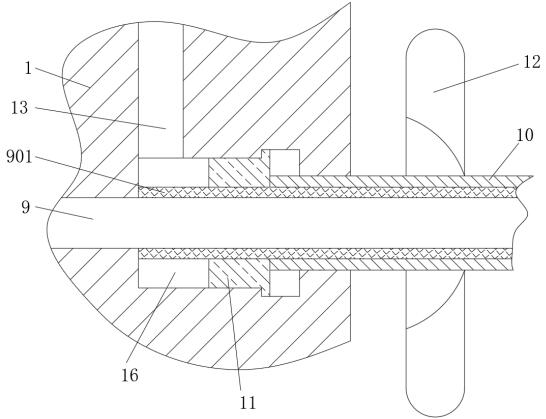

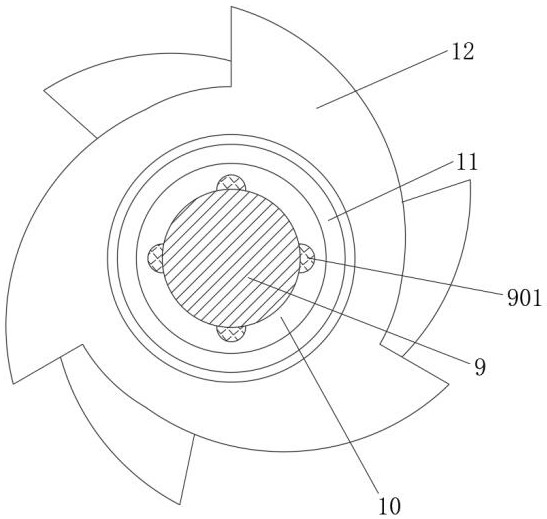

[0022] Reference Figure 1-Figure 2 As well as Figure 4There are four two -symmetrical passage channel 13 and stairway cavity 16 at both ends of the rack 1, a saturated hydraulic oil filled with the pressure channel 13 and the staircase 16Connect, there is a Pistons 14 on the other end of the event. The piston 14 is a fixed connection rod 15 at the end of the sub -ingredient 3, and the top of the connection rod 15 is hinged at the bottom of the sieve plate 4 to make the positive sieve board 4 4Torn blade 8 is close to 4 when the hydraulic oil is squeezed by the squeezing of the sieve. The tear blade here drives the scrap steel on the sieve 4 to the direction of the blade wheel II 12. At this time, Make Sieva 4 for irregular vibration, so that when the Sieve Board 4 is vibrated with rules, the piston 14 on both sides can drive the piston 14 to do irregular movement.The hydraulic oil within the side pressure channel 13 of the side enables the hydraulic oil to push the variable roller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com