Assembled generator and range extender

A generator and assembled technology, applied in the shape/style/structure of winding conductors, windings, motor vehicles, etc., can solve the problems of limited popularization, crowded installation space, difficulties, etc., achieve shortened axial size, and facilitate installation and use , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

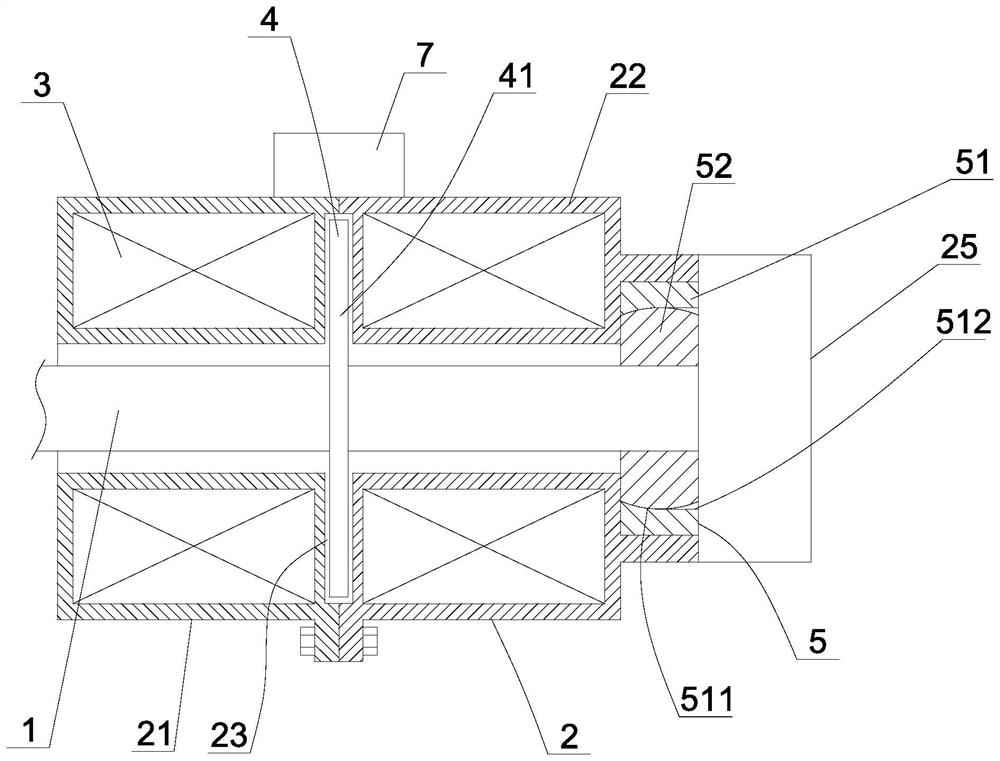

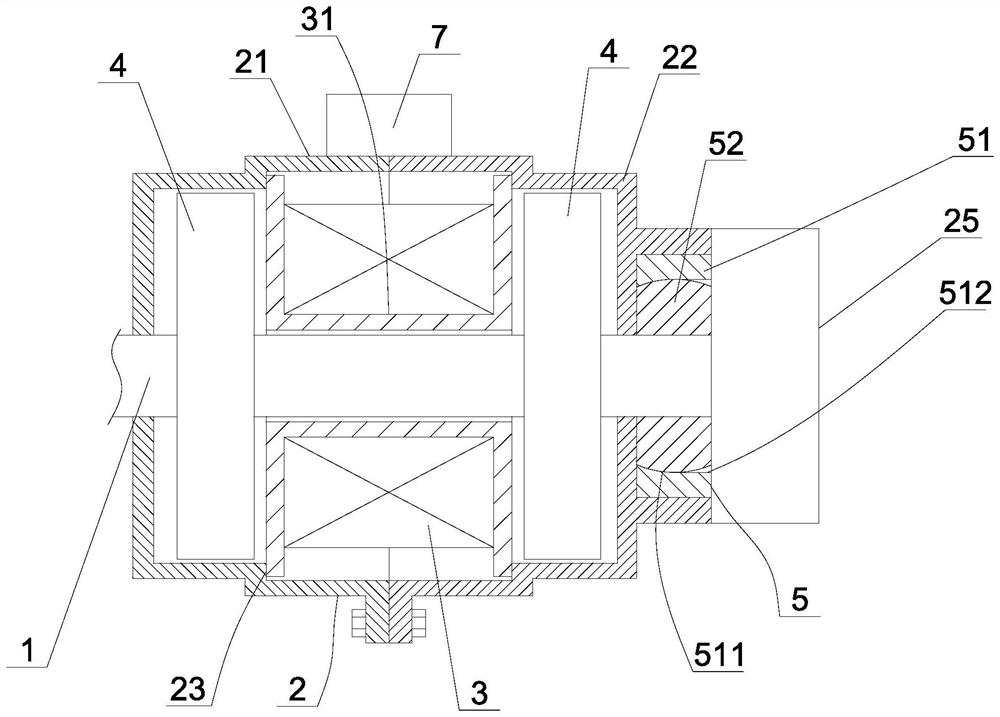

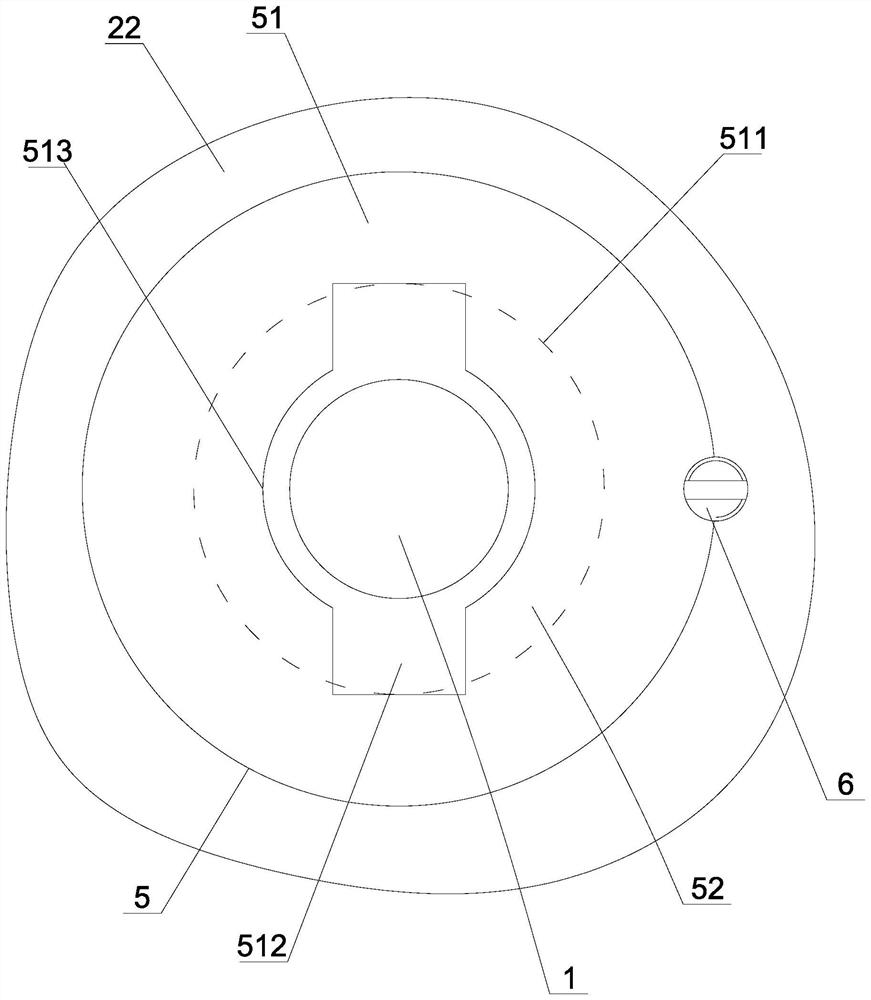

[0059] Embodiment 1: as figure 1 As shown, an assembled generator, which is suitable for the range extender of electric vehicles, specifically includes a motor housing 1, a rotor shaft 2 arranged in the motor housing, a junction box 7 for connecting input and output cables, a control 15, the rotor 4 and the stator winding 3 are sequentially arranged in the motor housing in the axial direction of the rotor shaft. They are sequentially arranged in series in the axial direction, so as to facilitate the user's assembly. The transfer box facilitates the electrical connection between the stator winding and the charger or other electrical equipment.

[0060] As those skilled in the art should know, the two ends of the rotor can form an end surface magnetic field, and the magnetic force lines output from one end and return to the other end. Therefore, when the rotor shaft is driven by the output shaft of the engine to rotate, and then drives the rotor to rotate, the rotor rotates re...

Embodiment 2

[0076] Embodiment 2: a kind of range extender, such as Figure 4 , Figure 5 As shown, it includes an engine 10 with an outer casing 101 and an output shaft 102, and a double-stator generator as described in Embodiment 1. The rotor shaft of the generator is connected to the output shaft of the engine, and the connection end of the motor casing is connected to the casing of the engine. body connected. Specifically, the assembly of the range extender includes the following steps:

[0077] a. Install the stator windings into the first housing and the second housing respectively, the stator windings are lower than the openings of the first housing and the second housing, so that at the openings of the first housing and the second housing Form a concave semi-installation cavity;

[0078] b. Connect the rotor shaft with the output shaft of the engine, and fix the connecting end of the first casing on the outer casing of the engine, and at this time, the rotor shaft passes through...

Embodiment 3

[0092] Embodiment 3: a kind of range extender, such as Figure 10 As shown, it includes an engine with an outer casing and an output shaft, and a dual-rotor generator as described in Embodiment 1. The output shaft of the engine is connected to the rotor shaft of the generator, and one end of the motor casing of the generator is connected to the outer casing of the engine. connect. When the engine is running, the output shaft can drive the rotor shaft to rotate, and then realize the power generation of the assembled generator, and the electricity generated by the assembled generator can charge the battery of the electric vehicle, so as to satisfy the driving of the electric vehicle. Specifically, the assembly of the range extender system includes the following steps:

[0093] a. Install the first mounting bracket with magnetic steel on the front side of the rotor shaft, and let the front end of the rotor shaft pass through the center hole of the first housing. At this time, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com