Fireproof and flame-retardant multi-layer composite cable and preparation method thereof

A multi-layer composite, fire-resistant and flame-retardant technology, which is applied in the field of power cables, can solve problems such as potential safety hazards in use, and achieve the effects of improving safety in use, simple assembly and manufacturing, and ensuring fire-resistant and flame-retardant protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

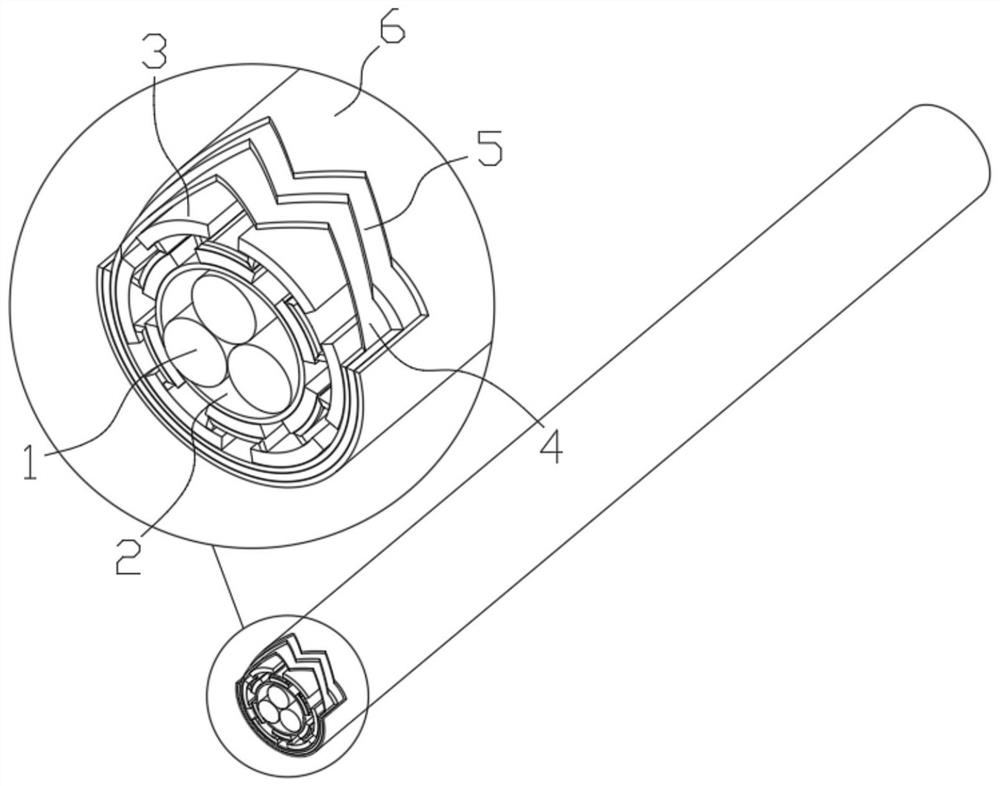

[0037] like figure 1 As shown in the figure, a fire-resistant and flame-retardant multilayer composite cable includes three insulating cable cores 1. On the outside of the insulating cable cores 1 from inside to outside, there are sequentially arranged cables that wrap all the insulating cable cores 1 and are used to support the inner layer structure of the cable. The first support shielding layer 2, the splicing type fireproof layer 3 that wraps the first supporting shielding layer 2, the second supporting shielding layer 4 that wraps the splicing type fireproof layer 3 and is used to support the outer structure of the cable, wraps the second supporting shielding layer 4. 2. The flame-retardant layer 5 supporting the shielding layer 4 and the outer sheath 6 wrapping the flame-retardant layer 5 and used to prevent cable abrasion;

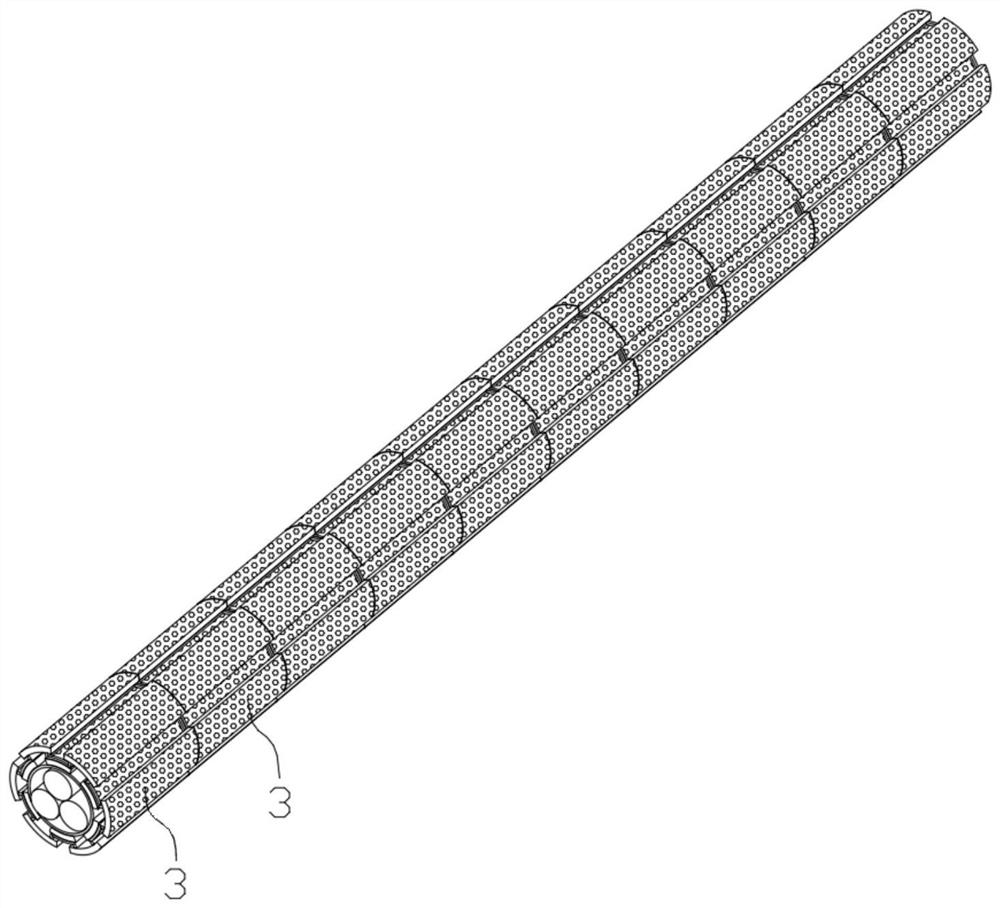

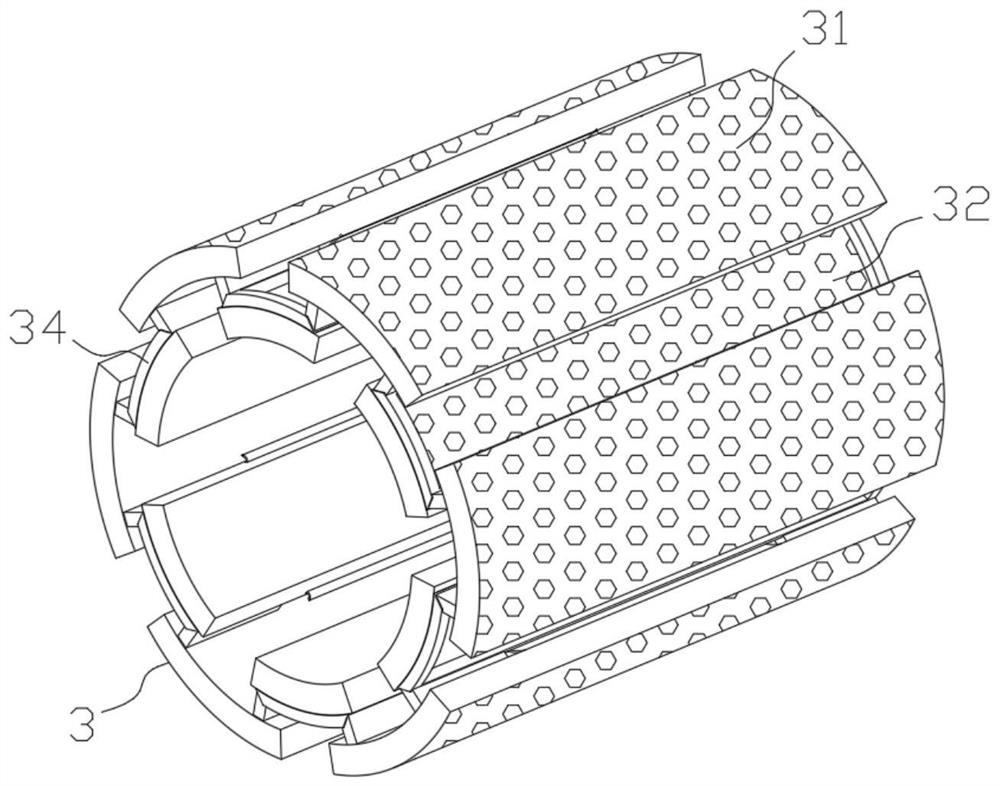

[0038] like image 3 , 4 As shown, the splicing type fireproof layer 3 includes arc-shaped outer sheets 31 distributed at equal intervals in the ...

Embodiment 2

[0051] This embodiment is basically the same as Embodiment 1, except that the end face of the arc-shaped inner sheet 32 of each segment of the splicing type fireproof layer 3 is bonded to the arc-shaped inner sheet 32 of the adjacent splicing type fireproof layer 3 Through the above-mentioned arrangement, the manufacturing difficulty of the arc-shaped outer sheet 31 and the arc-shaped inner sheet 32 can be reduced, but the splicing type fireproof layer 3 after bonding is not easy to bend, etc.

Embodiment 3

[0053] This embodiment is basically the same as Example 1, except that 5 parts of aluminum sulfate octadecahydrate, 3 parts of calcium carbonate and 6 parts of base material are selected according to the parts by mass, and then aluminum sulfate octadecahydrate, calcium carbonate are selected. Pressed into microspheres with a particle size of 2 mm, respectively, to obtain aluminum sulfate octadecahydrate microspheres and calcium carbonate microspheres.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com