Servo motor logistics roller

A servo motor and logistics technology, applied in conveyor objects, rollers, conveyors, etc., can solve the problems of uncontrolled, high maintenance cost, and short gear wear life, and achieve simple assembly and manufacturing, convenient follow-up maintenance, The effect of lower production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the content of the present invention more clearly understood, the present invention will be further described in detail below based on specific embodiments and in conjunction with the accompanying drawings.

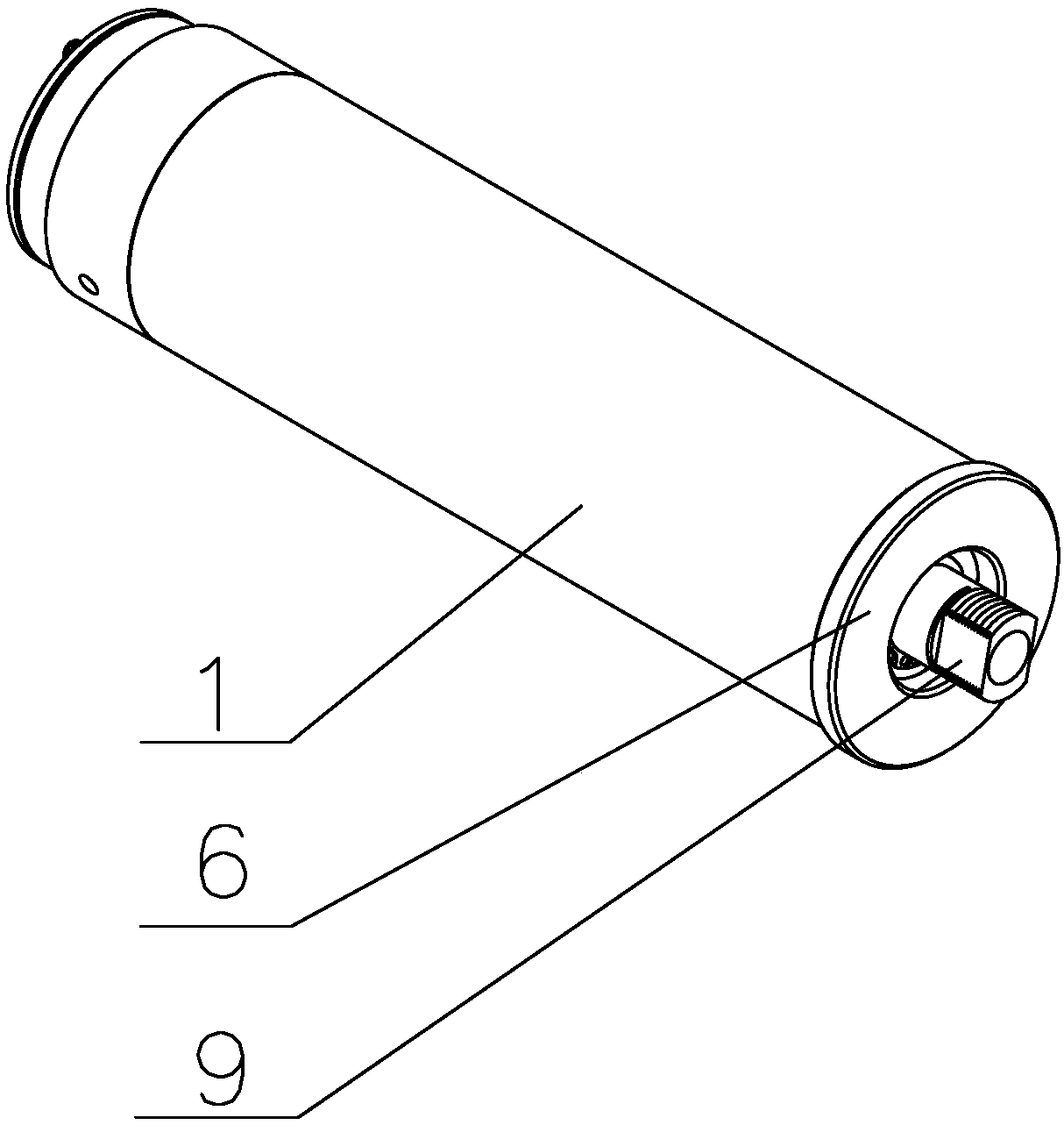

[0016] Such as figure 1 , 2 As shown, a servo motor logistics roller includes a drum 1, a motor casing 2, a main shaft 3, a magnetic steel 8 and an iron core 7, the magnetic steel 8 is arranged on the inner wall of the motor casing 2, and the iron core 7 is set on the main shaft 3 And fixedly connected with the main shaft 3, the roller 1 is sleeved on the motor casing 2 and fixedly connected with the motor casing 2 by screws; the front end of the motor casing 2 is connected with a front end cover 4, and the motor casing 2 The rear end is provided with a middle end cover 5, and the rear end of the drum 1 is fixed with a rear end cover 6, and the space between the middle end cover 5 and the rear end cover 6 is used to accommodate an encoder, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com