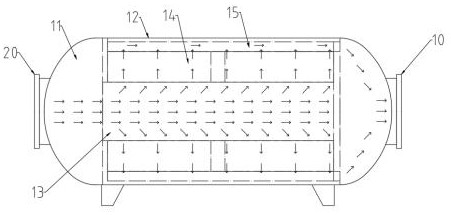

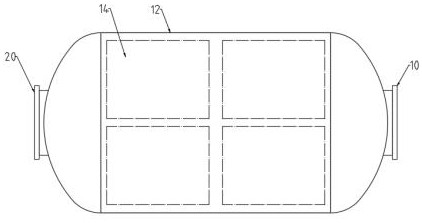

Nitrogen oxide waste gas treatment equipment

A technology for waste gas treatment equipment and nitrogen oxides, which is applied in the direction of gas treatment, air quality improvement, chemical instruments and methods, etc. It can solve the problems of ozone layer breakdown, reduce waste gas treatment efficiency, and difference in service life of adsorbents, etc., to ensure cleanliness Orderly, reducing the difficulty of maintenance and cleaning, and improving the efficiency of waste gas treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

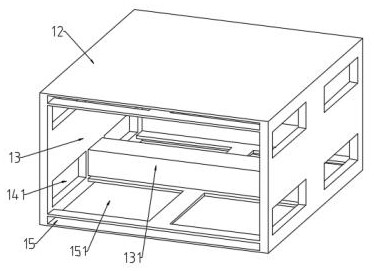

[0034] In another embodiment, both sides of the sealing membrane 152 are installed on the electric sliding rails. When the adsorption bed 14 is opened, the electric sliding rails first drive the sealing membrane 152 to close the through holes 151, so that the adsorption bed 14 is pulled out During the process, the overflow of exhaust gas can be completely avoided.

[0035] The adsorption bed body 14 is provided with a baffle plate 143 on the side close to the diffusion channel 13. The baffle plate 143 and the adsorption bed body 14 are connected by a telescopic assembly, and the telescopic assembly is an electric cylinder, an air cylinder, a hydraulic cylinder, etc. , in this embodiment, the telescopic assembly is a rack and pinion mechanism, such as Figure 10 , the telescopic assembly includes a connecting rod 140, one end of the connecting rod 140 is connected with the baffle 143, and the other end extends into the adsorption bed 14, the connecting rod 140 has a tooth surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com