Filling block, measuring device and method for measuring gear oil film thickness through eddy current method

A gear oil and film thickness technology, applied in the field of gear lubrication, can solve the problems of difficult gear arrangement and difficult application of gears in eddy current sensors, and achieve the effects of simple structure, accurate measurement, and saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

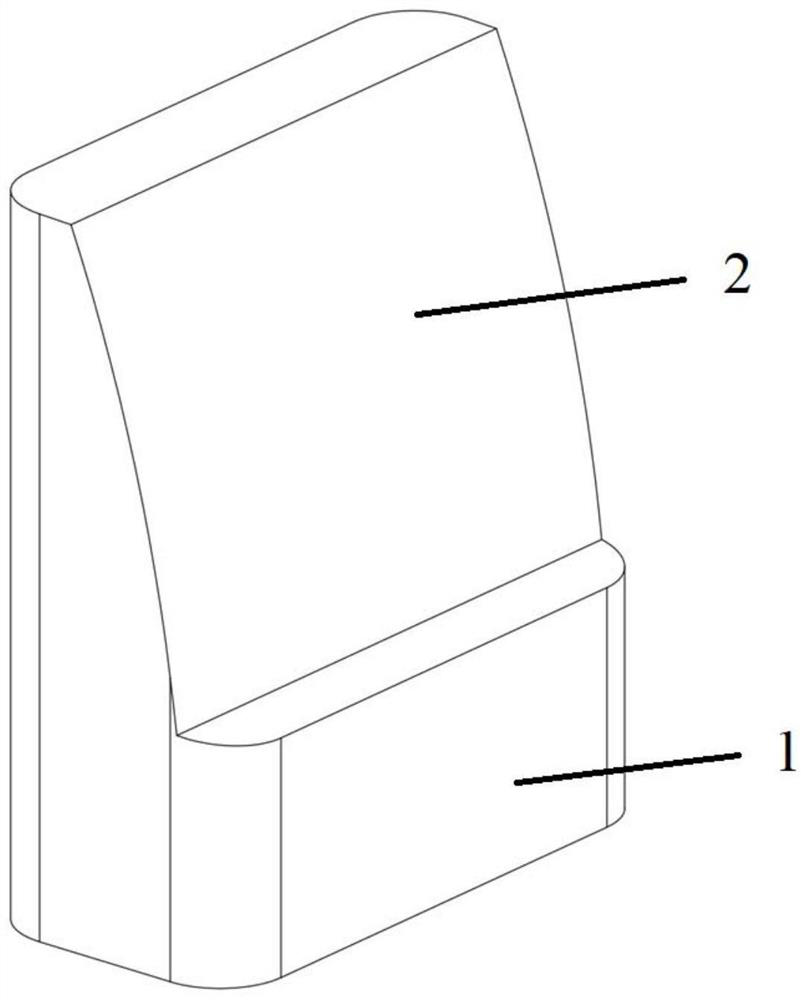

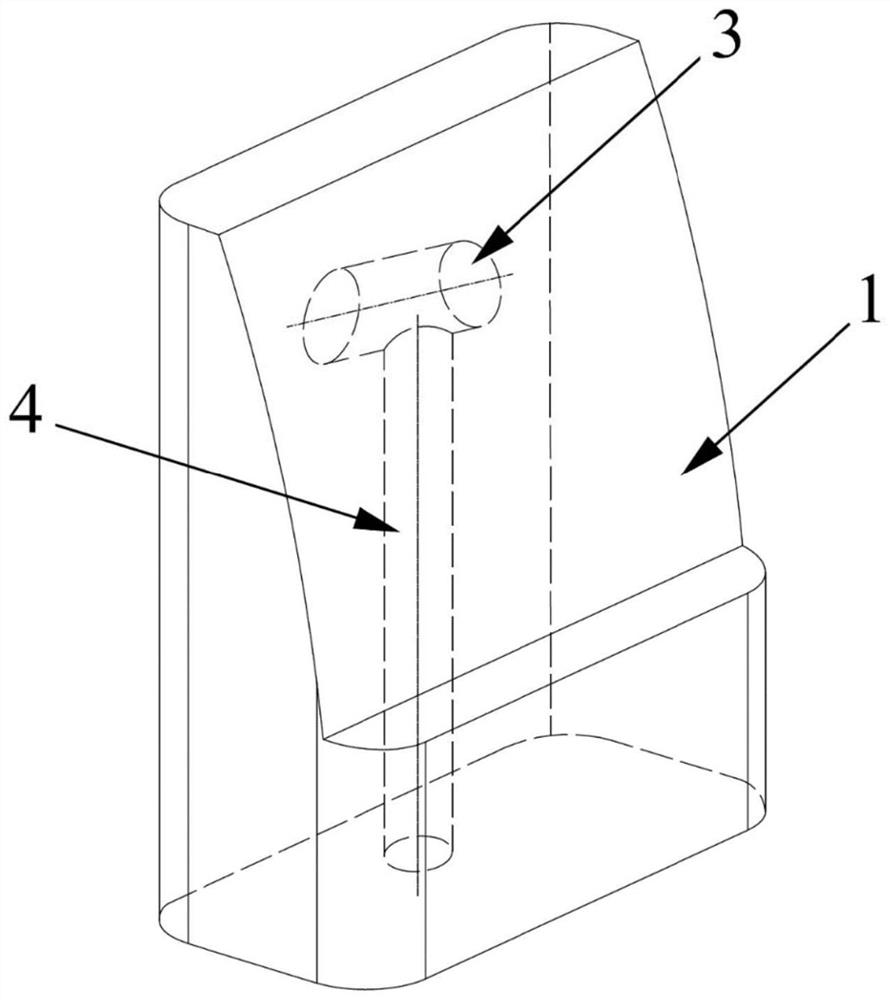

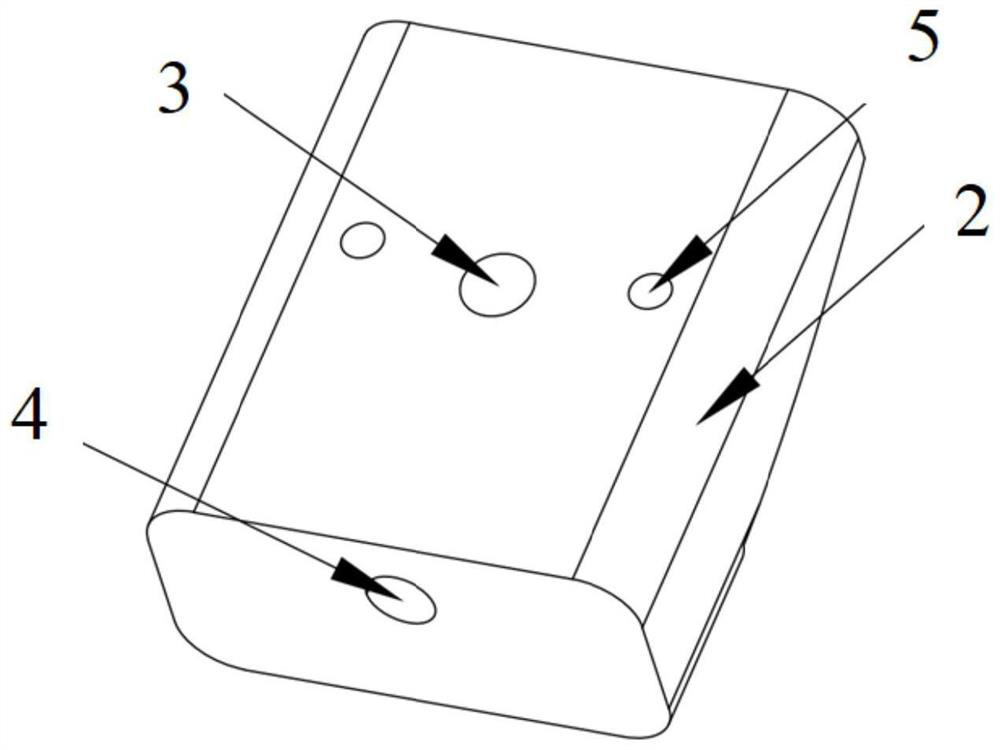

[0042] Follow the above technical solutions, such as Figure 1 to Figure 4 As shown in the figure, an eddy current method is used to measure the thickness of the gear oil film. It includes a filler body 1 and a sensor mounting block 2 mounted on the filler body 1. the top connection;

[0043] The filler block body 1 is generally in the shape of a cuboid. The width of the top end where the filler block body 1 is connected with the sensor mounting block 2 is greater than the width of the bottom end where the sensor mounting block 1 is connected with the filler block body 2. The sensor mounting block 2 is connected with the filler block body. A step surface is formed between 1;

[0044] The shape of the step surface is the same as the shape of the tooth slot of the gear to be measured, the surface of the sensor mounting block 2 in contact with the step surface is the same as the shape of the tooth surface of the gear to be measured, and the step surface is the same as the sensor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com