Engine cover pneumatic telescopic supporting mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below by means of specific embodiments:

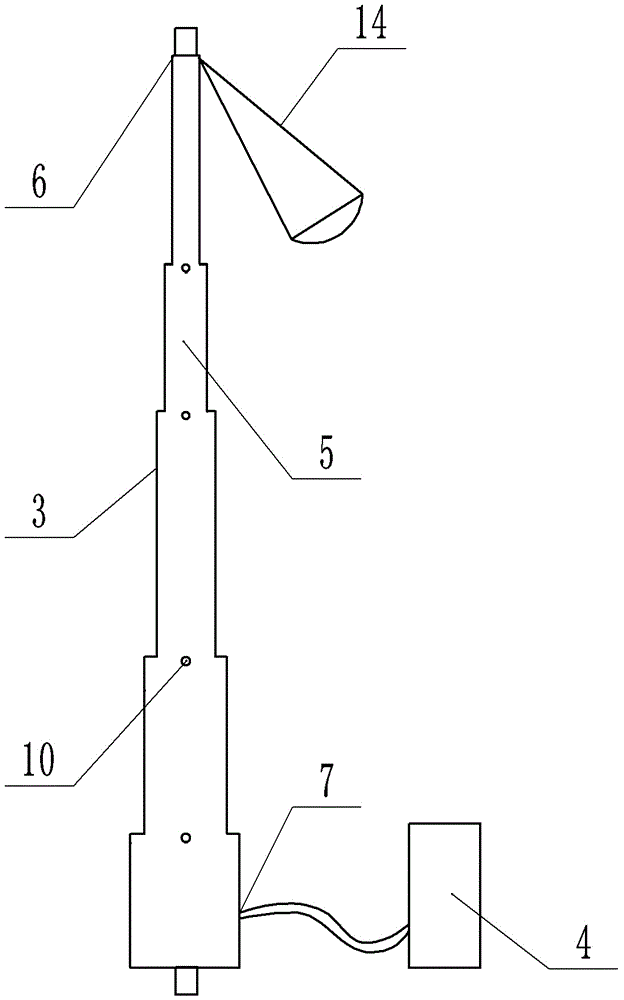

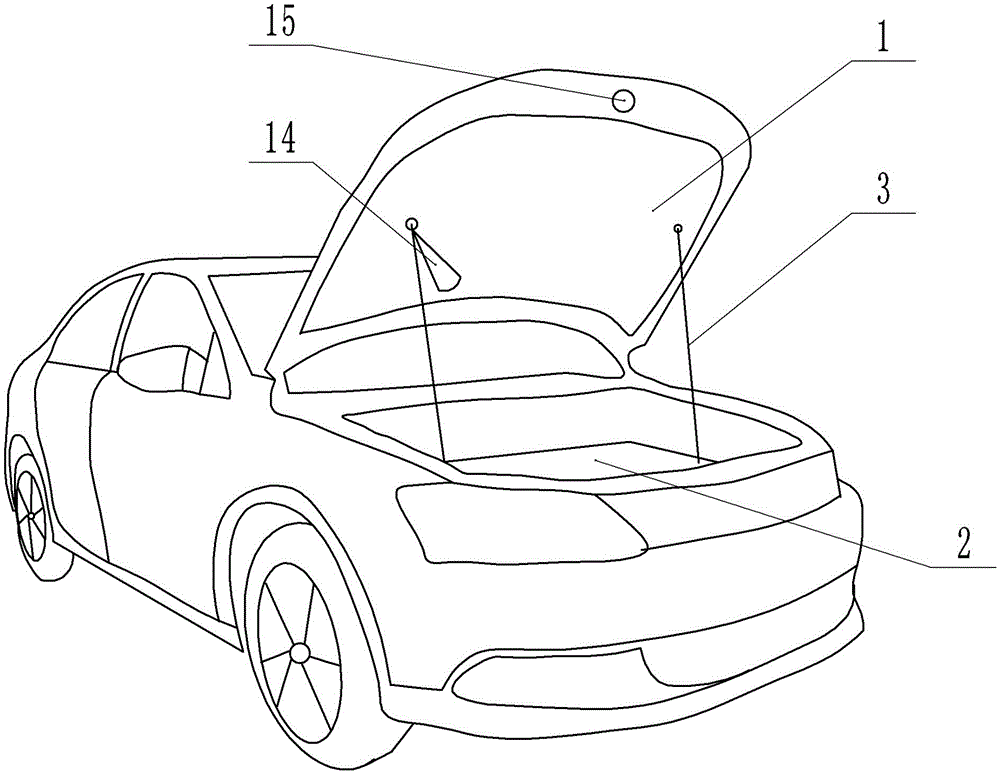

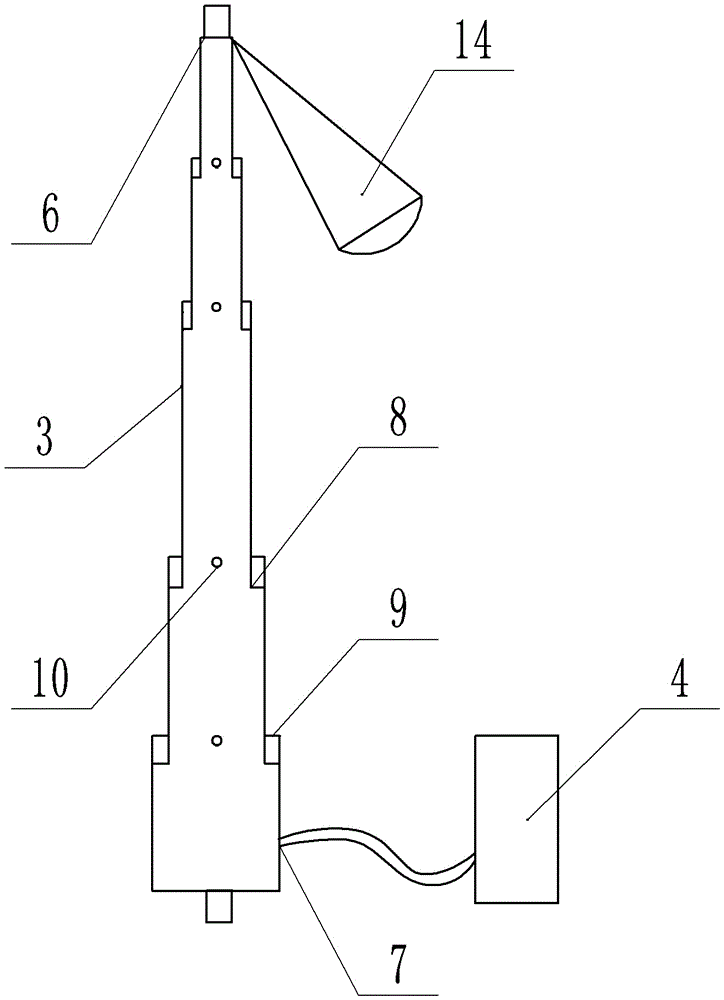

[0019] The reference signs in the drawings of the description include: engine cover 1, engine compartment 2, pneumatic telescopic rod 3, inflation device 4, single rod 5, air outlet 6, air inlet 7, inner shoulder 8, outer shoulder 9, Position slot 10, spring seat 11, spring 12, ball pin 13, LED lamp 14, button 15.

[0020] The embodiment is basically as attached Figure 1 to Figure 3 Shown: engine hood pneumatic telescopic support mechanism, including engine hood 1, engine compartment 2 and control mechanism, also includes pneumatic telescopic support device, pneumatic telescopic support device includes pneumatic telescopic rod 3 and inflation device 4, the two ends of pneumatic telescopic rod 3 are respectively The engine cover 1 and the engine compartment 2 are screwed together. The pneumatic telescopic rod 3 is formed by arranging several single rods 5 from top to bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com