Heading machine cutter head and heading machine

A technology of cutter head and machine cutter, which is applied in mining equipment, tunnels, earth-moving drilling, etc., and can solve problems such as affecting construction progress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

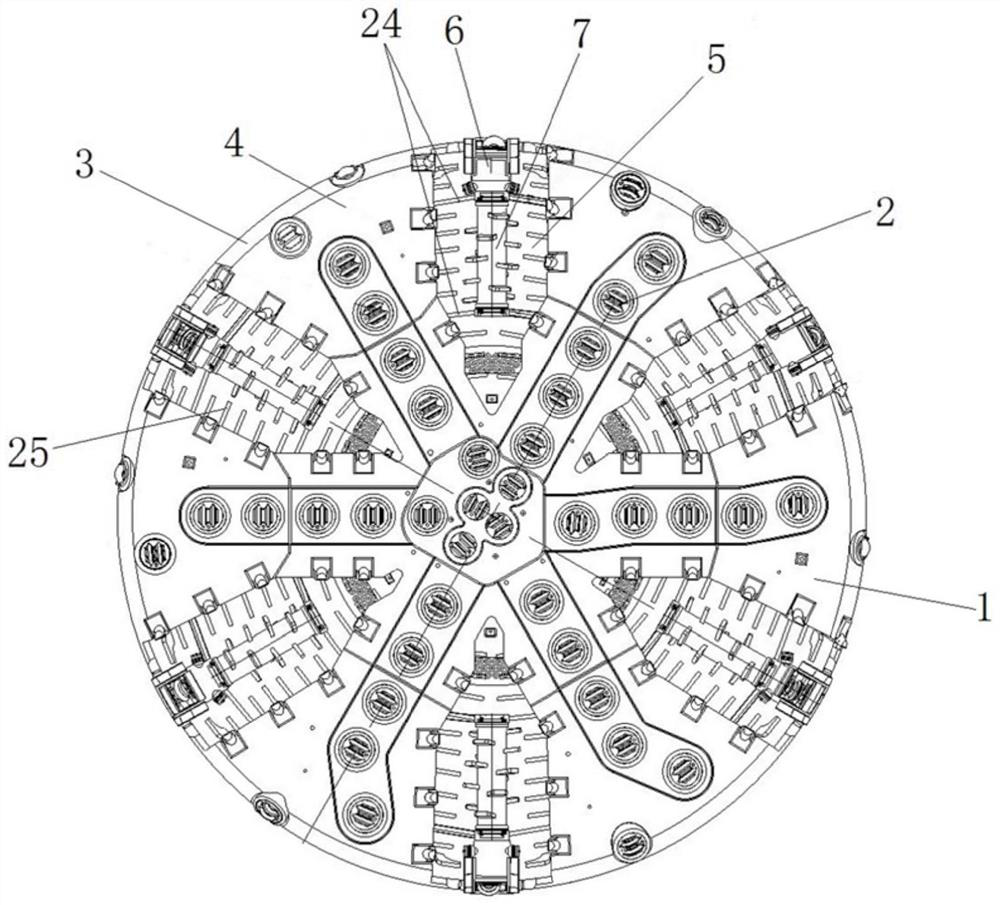

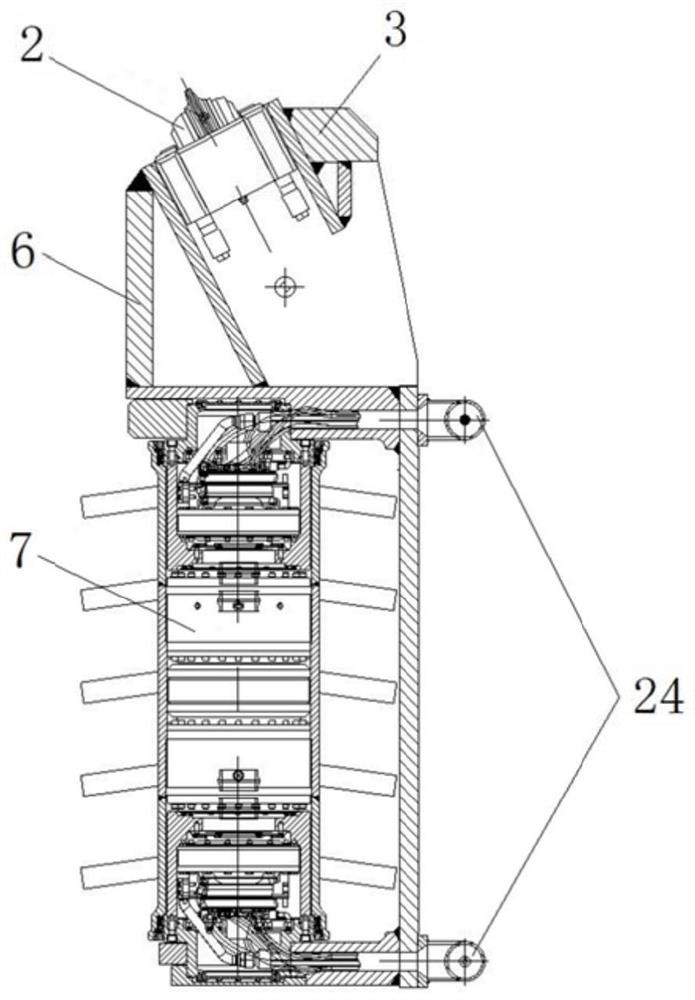

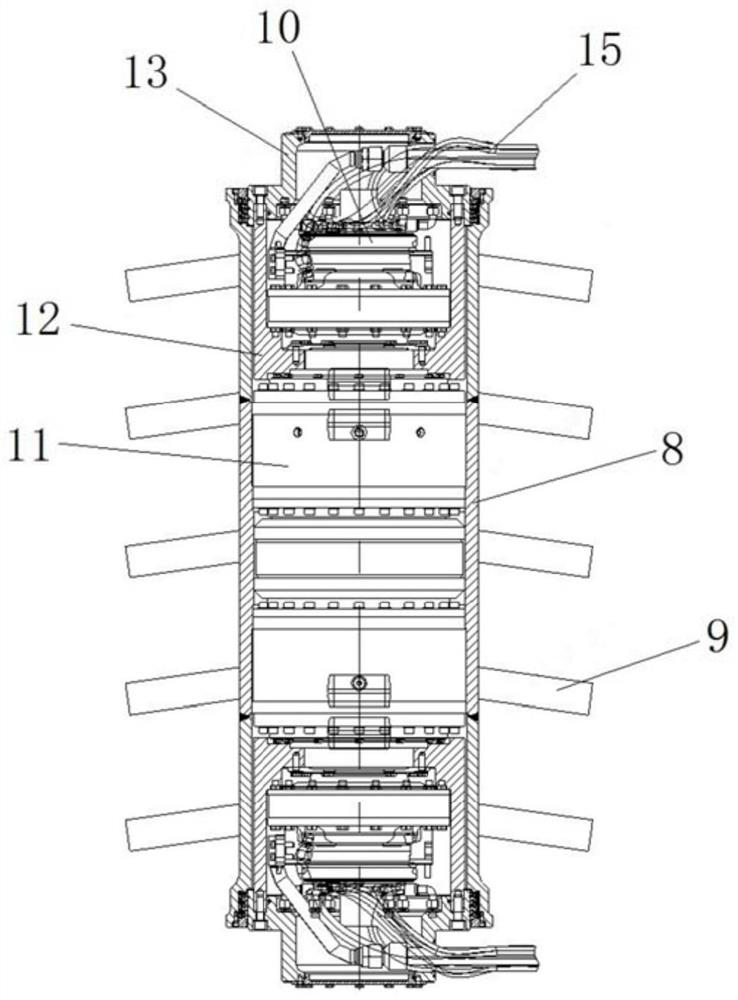

[0075] The roadheader provided in this embodiment includes a shield body, a main drive is arranged in the shield body, and a cutter head is arranged on the main drive. The structure of the cutter head is as follows: figure 1As shown, the cutter head includes a cutter head body 1 and a cutter 2 disposed on the cutter head body 1 . The cutter head body 1 includes a large ring 3 on the outside and a plurality of main beams 4 located in the large ring 3. The plurality of main beams 4 are radially distributed with the center of the cutter head main body 1 as the center, and are far from the center. One end is connected with the large ring 3 , and two adjacent main beams 4 cooperate with the large ring 3 to form a slag discharge port 5 , and some cutters 2 are arranged on each main beam 4 . During operation, the cutter head rotates under the drive of the main drive, excavating the face of the tunnel through cutter 2, and the excavated muck enters the soil bin on the rear side of the...

specific Embodiment 2

[0084] The specific embodiment 2 of the roadheader provided by the present invention is mainly different from the embodiment 1 in that: in the embodiment 1, the rotation axis of the soil stirring structure of the soil crushing device is arranged along the radial direction of the cutter head body. In the present embodiment, the rotation axis of the soil stirring structure of the soil crushing device is arranged in the slag discharge opening so as to intersect with the radial direction of the cutter head body.

specific Embodiment 3

[0085] The specific embodiment 3 of the roadheader provided by the present invention is mainly different from the embodiment 1 in that: in the embodiment 1, a grid and a soil crushing device are arranged at the slag discharge port to cooperate with the slag soil passing through the slag discharge port. Broken and refined. In this embodiment, the soil crushing device is only provided at the slag discharge port, and the stirring area of the soil crushing device is increased in order to avoid the occurrence of a large soil crushing blind area.

[0086] The specific embodiment 4 of the roadheader provided by the present invention is mainly different from the embodiment 1 in that: in the embodiment 1, the grille is a blocking tooth structure. In this embodiment, the grid is a grid-like structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com