Frame beam prestress reinforcing device and construction method thereof

A reinforcement device and frame beam technology, applied in the direction of joists, girders, truss beams, etc., can solve problems such as inability to perform reinforcement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

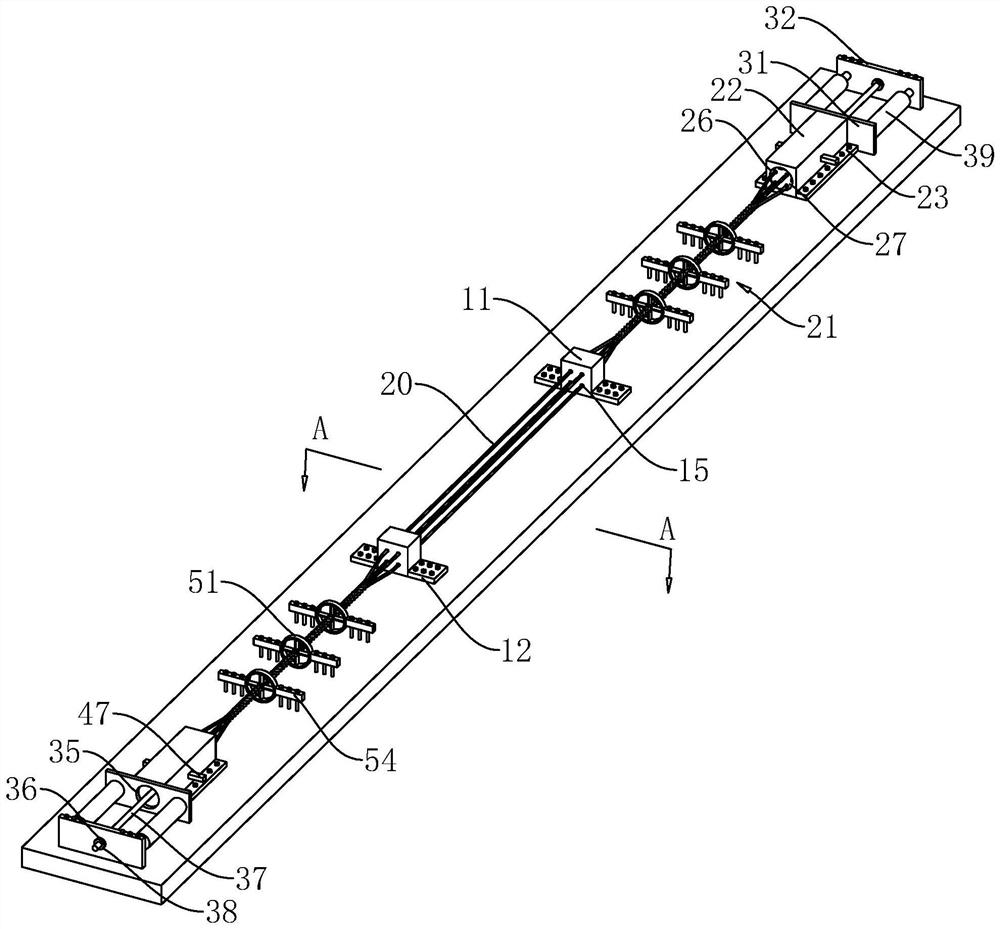

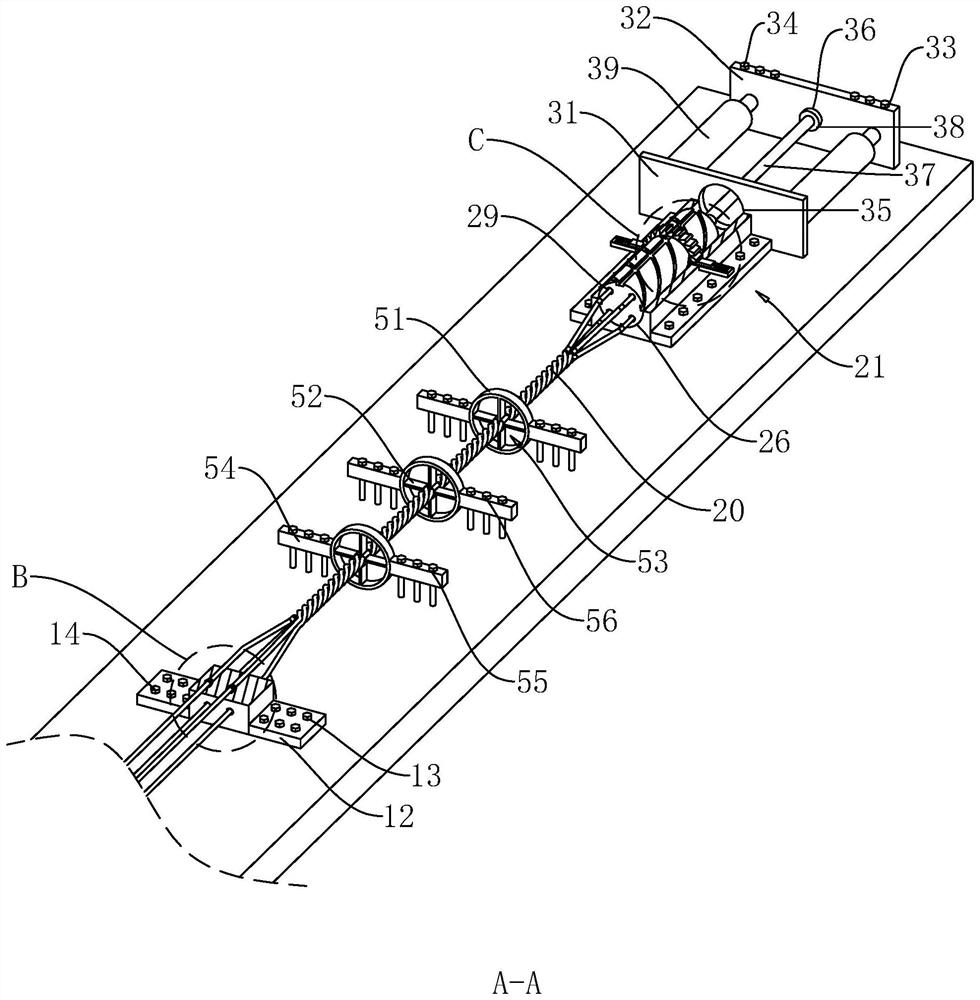

[0032] Attached to the following Figure 1-6 This application will be described in further detail.

[0033] The embodiment of the present application discloses a frame beam prestressing reinforcement device and a construction method thereof. refer to Figure 1-3 As shown, the frame beam prestressing reinforcement device and the construction method thereof include two groups of support blocks 11 installed on the bottom surface of the frame beam along the length direction of the frame beam, and the two groups of support blocks 11 are oppositely arranged, and the support blocks 11 are blocks in the shape of a rectangular parallelepiped. structure. Both the front and rear sides of the support block 11 are welded with a support straight plate 12 , and the support straight plate 12 is provided with two sets of bolt through holes 13 penetrating the upper and lower sides of the support straight plate 12 along the length direction of the frame beam, and each set of bolt through holes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com