Unpowered obstacle crossing snow sweeper

A snow removal vehicle and power technology, which is applied to snow surface cleaning, construction, cleaning methods, etc., can solve the problems of missing a large area of snow by the snow pusher, the snow removal effect is not ideal, and the cleaning effect is reduced, and achieves a significant snow removal effect. Novel, quick installation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be described below with reference to the accompanying drawings and embodiments.

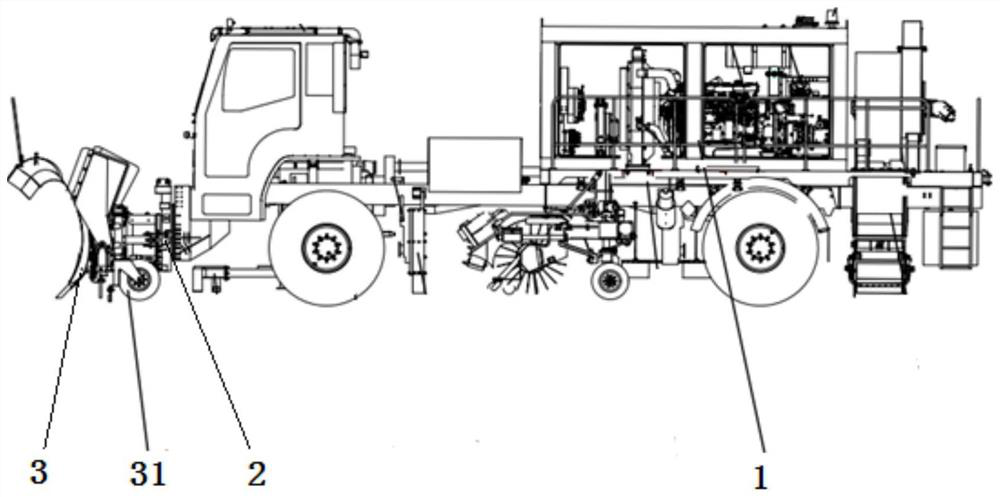

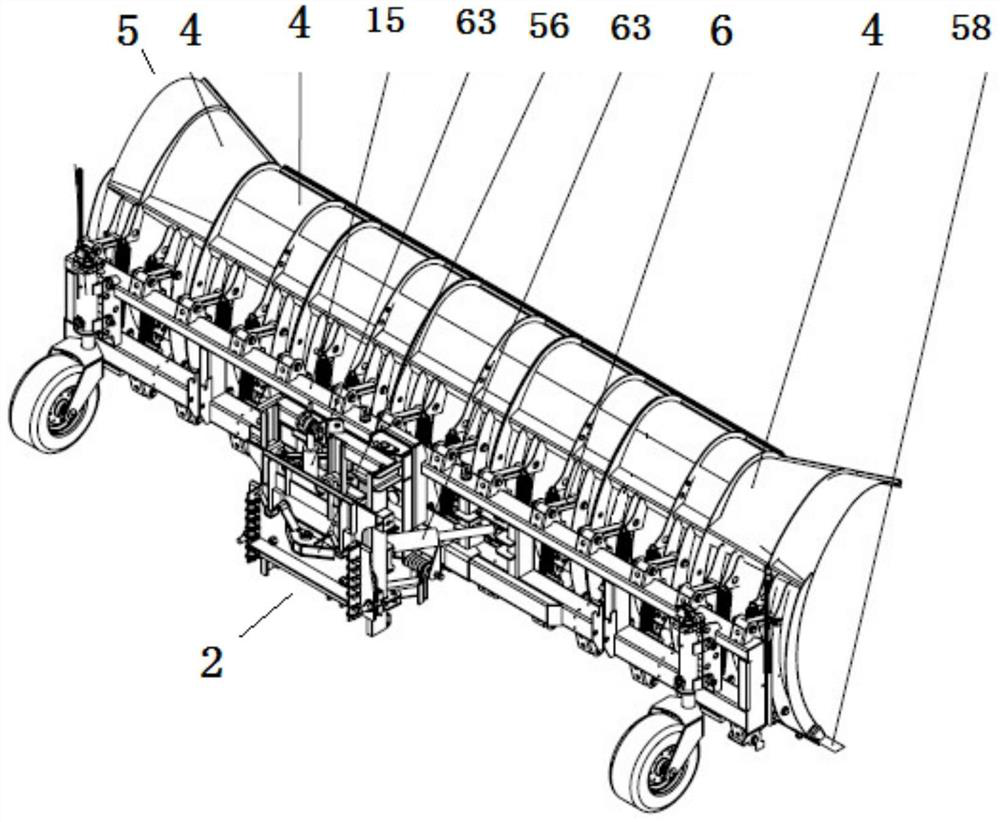

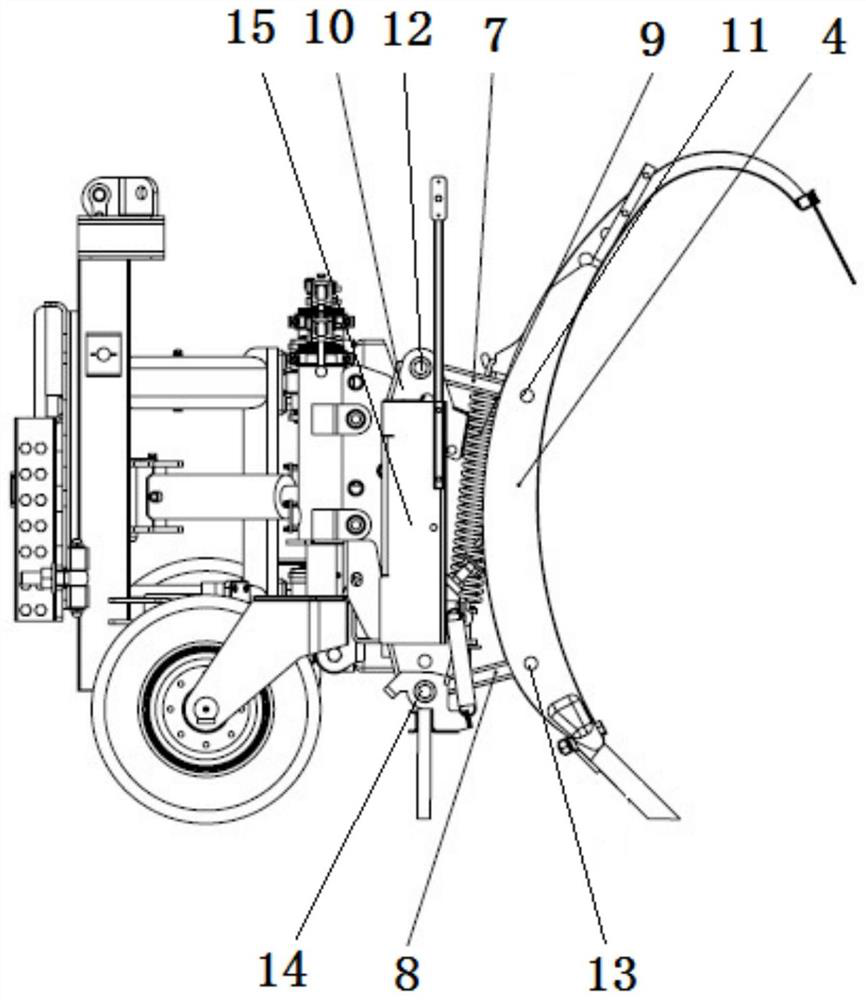

[0047] as attached figure 1 , figure 2 As shown in the figure, an unpowered obstacle-surmounting snow removal vehicle includes an automobile chassis 1, and the front end of the automobile chassis 1 is connected with a snow-pushing device 3 through a push-board support device 2, and is characterized in that the snow-pushing device 3 is composed of The snow pusher 5 composed of the unit snow pusher 4, the unit unpowered obstacle-crossing support device 6 and the main frame 15, which are arranged side by side, the side walls are in contact with each other and do not interfere with each other when moving, are composed of the unit snow pusher 4. Two juxtaposed units of unpowered obstacle crossing support devices 6 are connected with the main frame 15 to enhance the overall stability of the snowboard. When encountering a bump on the road, the unit snow pusher 4 corr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com