Material loading and transporting vehicle for coal mine

A technology for loading vehicles and materials, which is applied in the directions of safety devices, transportation and packaging, and load suspension components. It can solve the problems of equipment space waste, inability to place materials, and inability to use, etc., to reduce occupied space, increase lifting force, Guaranteed safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

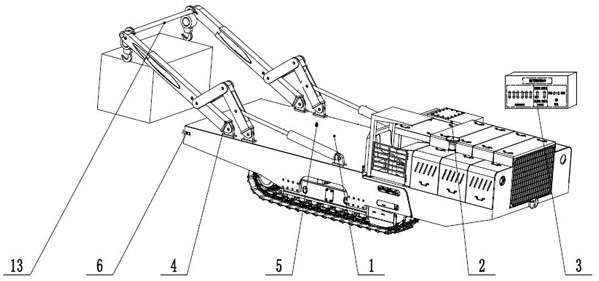

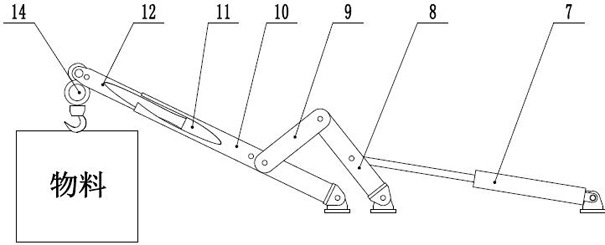

Please refer to Figure 1-2, a coal mine material loading vehicle, including a body 1, a power system 2 and a control system 3, the body 1 includes a main frame and a walking mechanism at the bottom, the power system 2 is installed on the main frame, and the power system 2 Including the explosion-proof engine system and hydraulic system, the explosion-proof engine outputs power, drives the hydraulic pump, and provides power for the hydraulic system. Hydraulic oil source, the control system 3 includes a local operating system and a remote control system, a hoisting system 4 and a fixing device 5 are installed on one end of the main frame surface of the body 1, and an anti-collision system 6 is installed on the edge of one end of the main frame, and an anti-collision system 6 is installed. It includes ranging sensor and controller. When the object to be lifted is close to the ranging sensor and less than the set safe distance during the lifting process, an alarm will be issued to p...

Embodiment 2

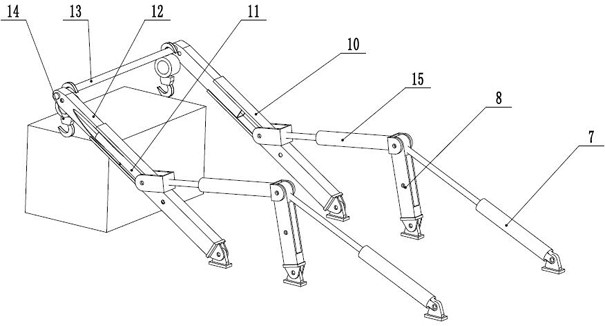

see image 3 The embodiment is further optimized on the basis of Embodiment 1. Specifically, the connecting rod 9 is replaced with a luffing cylinder 15, and the hoisting cylinder 7 is installed from the middle of the forearm 8 to the top of the forearm 8.

[0019] In this embodiment, when the weight of the object to be lifted is relatively large, the hoisting system 4 can replace the connecting rod 9 with the luffing cylinder 15. In this way, the original four-link mechanism becomes a variable-rod and long four-link mechanism, and the lifting cylinder is increased. 7. The force arm increases the lifting force, and the lifting position can be changed without changing the size of the crane, which solves the problem that the size of the lifting mechanism of the same lifting level is too large and cannot be used underground.

Embodiment 3

Referring to FIG. 4 , the present embodiment is optimized as follows on the basis of Example 1 or Example 2. Specifically, a magneto-induced displacement sensor 16 is provided inside the telescopic oil cylinder 11 .

[0021] In this embodiment, the magnetic displacement sensor 16 is installed in the telescopic oil cylinder 11, which can record the cylinder stroke in real time. When the anti-collision system 6 issues an alarm, the operating system automatically locks the operation solenoid valves of the lifting oil cylinder 7 and the luffing oil cylinder 15, and Actively control the telescopic cylinder 11 to extend the specified length L, and the system automatically determines whether the alarm is in contact. If it is still at a safe distance, the telescopic cylinder 11 extends the specified length L again until the alarm is lifted. At the same time, the hoisting cylinder 7 and the luffing cylinder 15 are automatically unlocked.

[0022] To sum up: the present invention adopts t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com