Wheel edge driving structure, wheel edge driving assembly and vehicle

A wheel-side drive and drive structure technology, which is applied to vehicle parts, electric vehicles, power plants, etc., can solve the problems of high weight and cost, large volume, etc., and achieve the effects of reduced production costs, enhanced ability to escape difficulties, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings. It should be understood that the specific embodiments described herein are only used to illustrate and explain the present invention, but not to limit the present invention.

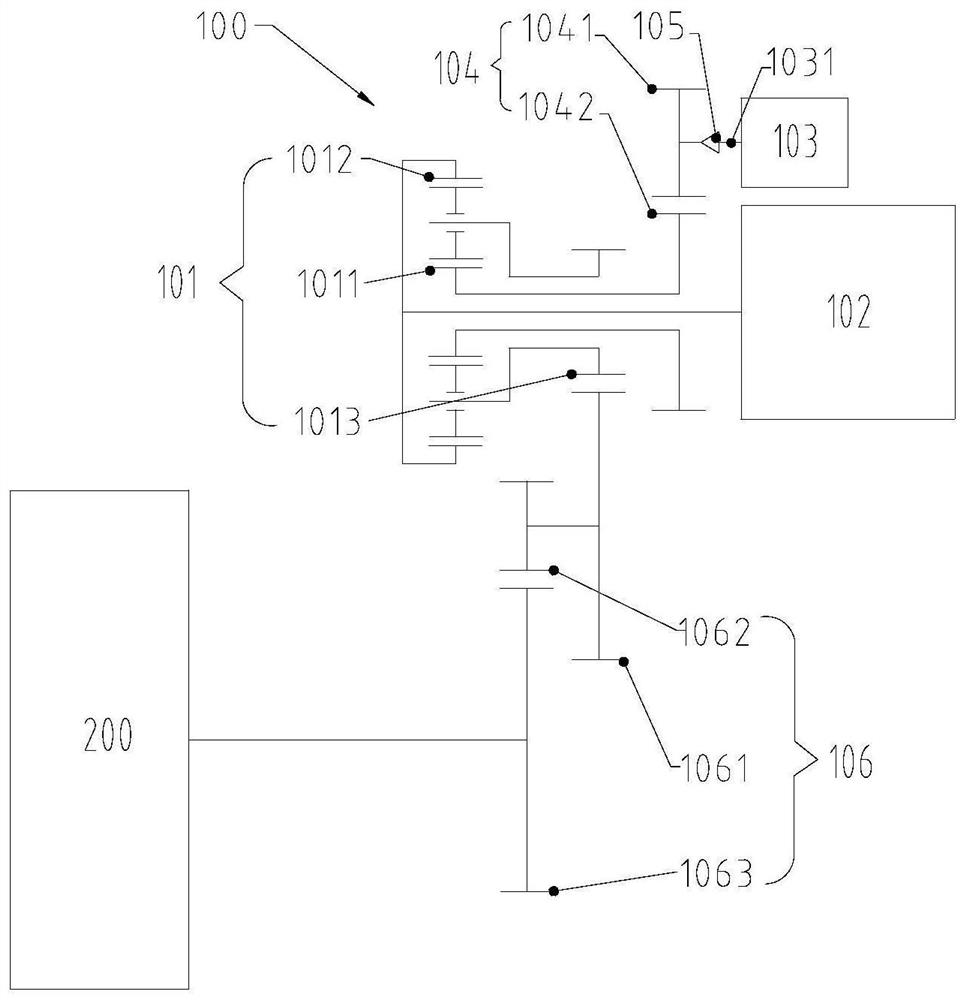

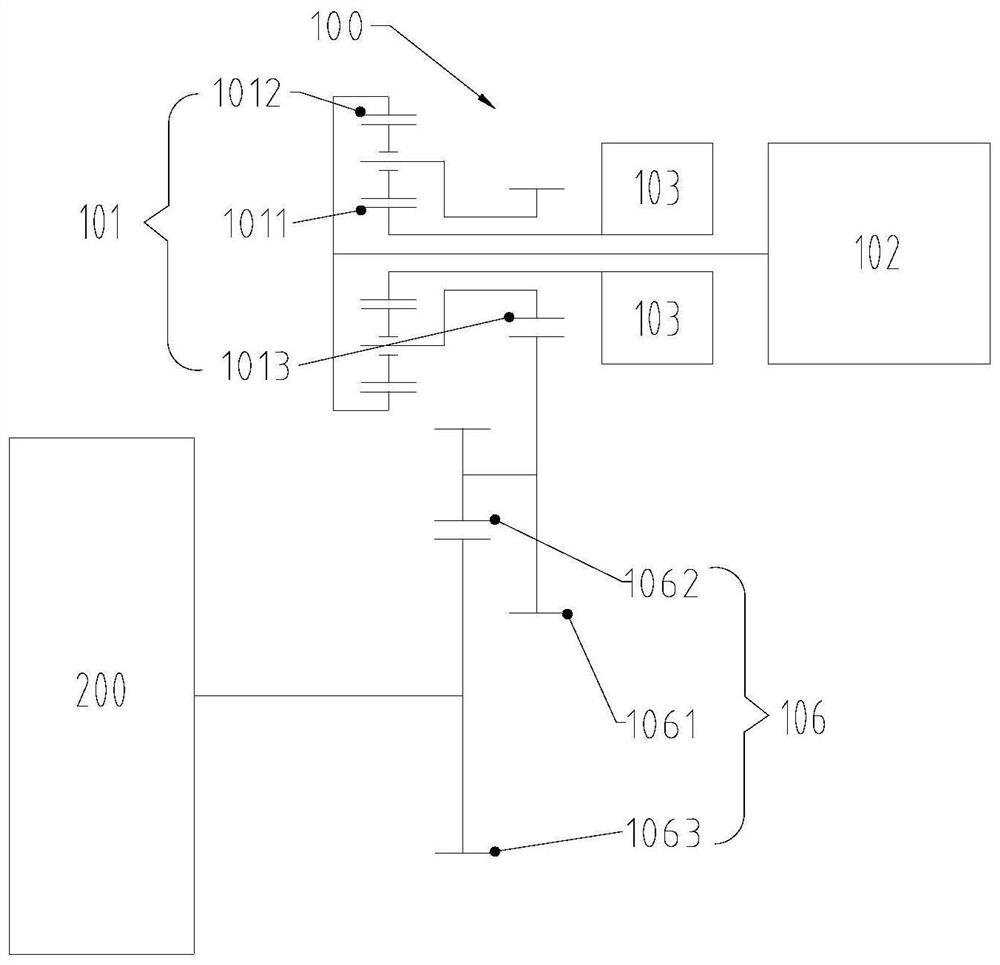

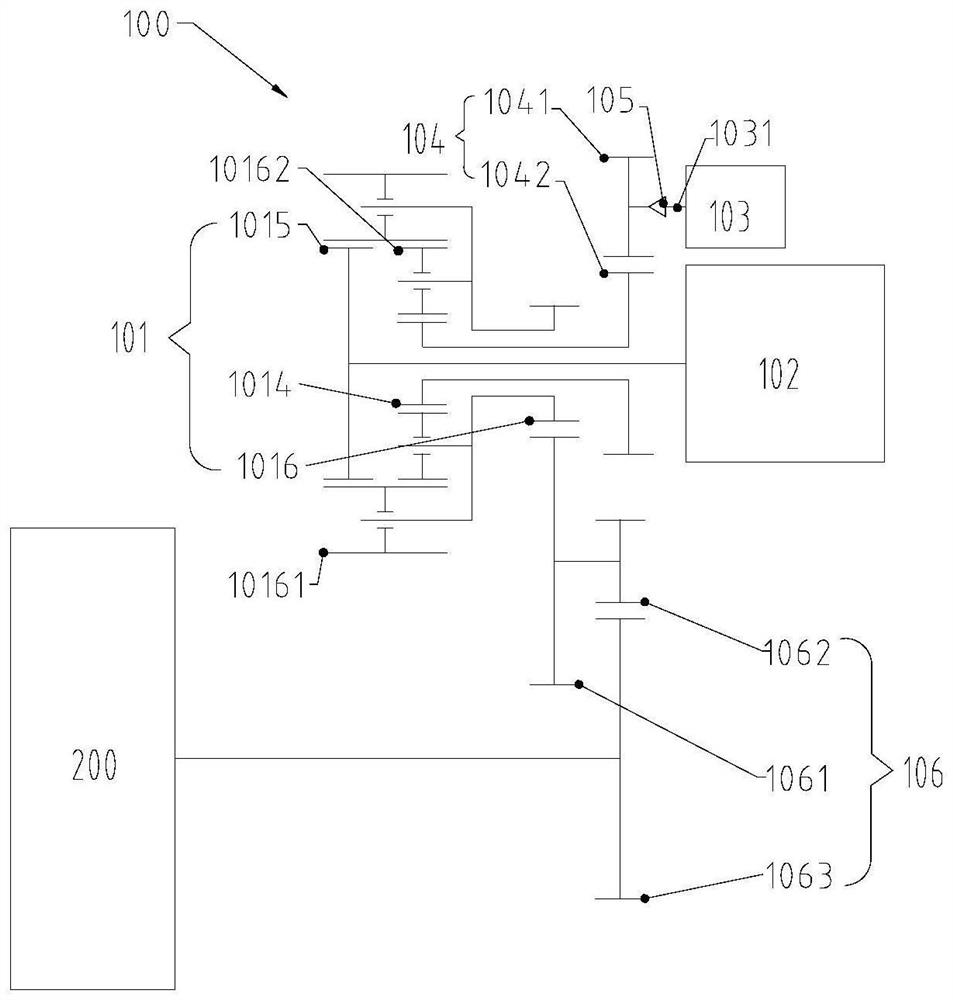

[0051] below with reference to the attached Figure 1 to Figure 14 The wheel drive structure 100 , the wheel drive assembly 300 and the vehicle of the present invention will be described.

[0052] The present invention provides a wheel drive structure with a novel structure. The wheel drive structure 100 includes a planetary gear train 101, a drive motor unit 102 and a speed regulating motor unit 103, wherein the planetary gear train 101 in this technical solution may include For the two different structural forms, correspondingly, the transmission structure between the planetary gear train 101 and the drive motor unit 102 and the speed regulating motor unit 103 is adap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com