Cleaning device for excess glue overflowing during plywood bonding

A cleaning device and a technology for plywood, applied in the field of plywood, can solve problems such as the impact of plywood quality, overflow of glue, and waste of glue, and achieve the effects of improving production quality, accelerating solidification, and avoiding offset

Active Publication Date: 2022-06-03

临沂友瑞木业有限公司

View PDF5 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004]

The purpose of the present invention is to solve the problem that the glue between the plywood is easy to overflow from the gap between the plywood when the existing plywood in the prior art is pressed and bonded, which not only causes waste of glue, but also easily affects the quality of the plywood. cause a certain impact, and the existing plywood residual glue cleaning device often only uses a scraper to scrape off the excess glue at one time, and the gap between the plywood may still continue to overflow the problem of glue, and a plywood is proposed Cleaning device for excess glue overflowing during bonding

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

[0025] working principle:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

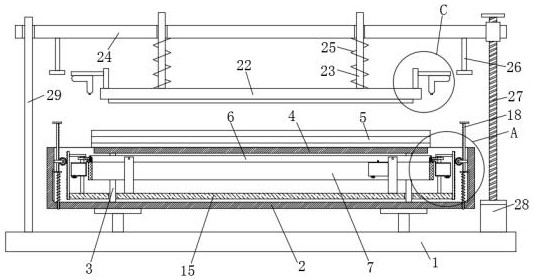

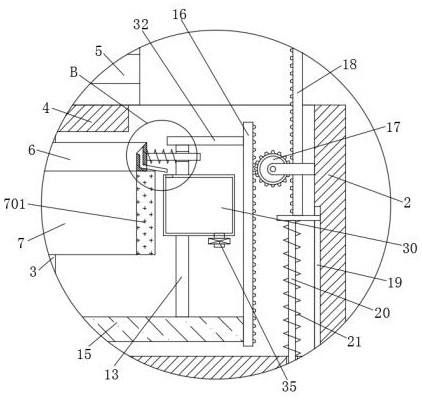

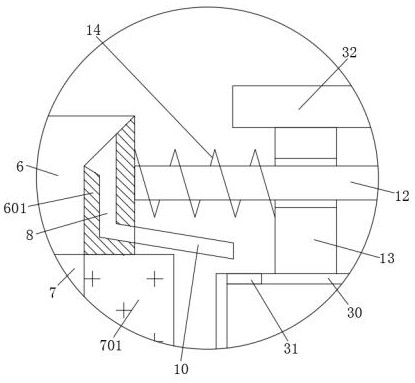

The cleaning device comprises a base, a fixing frame is fixedly installed at the upper end of the base, fixing rods are fixedly connected to the left side and the right side of the inner bottom end of the fixing frame, a workbench is fixedly connected to the upper ends of the fixing rods, a plywood body is arranged on the upper side of the workbench, and the plywood body is placed on the workbench; first cutting plates are arranged in the fixing frame and located on the front side and the rear side of the plywood body. When the device is used, the cutting plate I and the cutting plate II are arranged, so that residual glue overflowing from the outer end of the plywood body is conveniently scraped, and after scraping is completed, the cutting plate I and the cutting plate II continuously ascend to drive the heating plate I and the heating plate II to be attached to the outer end of the plywood body, so that the residual glue on the surface of the outer end of the plywood body is conveniently heated; and solidification of glue on the surface of the plywood body is accelerated, so that the glue in the plywood body can be prevented from overflowing again, and the production quality of the plywood body is improved.

Description

technical field [0001] The invention relates to the technical field of plywood, in particular to a cleaning device for overflowing excess glue when the plywood is bonded. Background technique [0002] Plywood is a three-layer or multi-layer board material made of wood segments that are cut into veneers or sliced into veneers, and then glued together with adhesives, usually with odd layers of veneers, and adjacent layers of veneers The fiber directions are glued perpendicular to each other. Plywood is one of the commonly used materials for furniture. It is one of the three major wood-based panels. It can also be used for aircraft, ships, trains, automobiles, buildings and packaging boxes. A group of veneer is usually formed by gluing the wood grain directions of adjacent layers perpendicular to each other. Usually, the surface plate and the inner layer are symmetrically arranged on both sides of the center layer or the core. It is a slab made of glued veneers crisscrossed...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B05C11/10B05C13/02B05C9/14B05D3/02B27D1/04

CPCB05C11/1039B05C13/02B05C9/14B05D3/0254B27D1/04Y02W30/62

Inventor 姚万忠

Owner 临沂友瑞木业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com