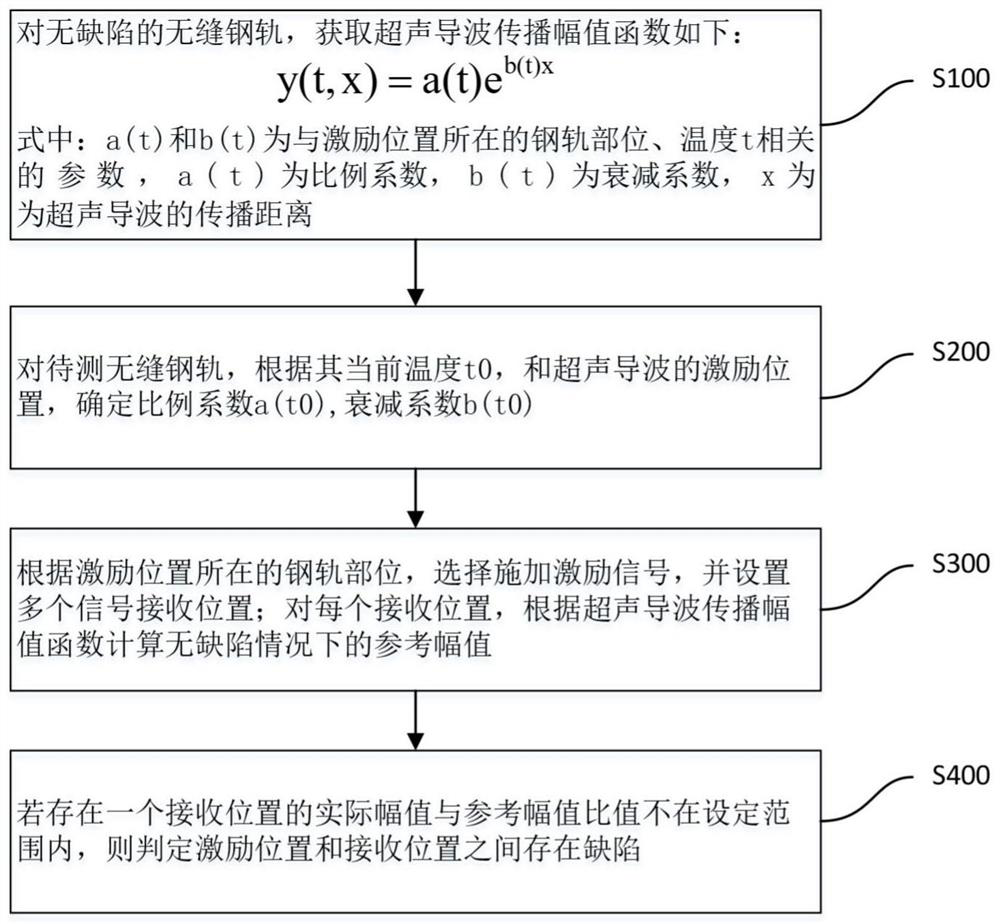

Seamless steel rail detection method and device based on guided wave attenuation and storage medium

A seamless steel rail and detection method technology, applied in the direction of measuring device, using sound wave/ultrasonic wave/infrasonic wave to analyze solid, using sound wave/ultrasonic wave/infrasonic wave for material analysis, etc., can solve false alarm detection, difficulty in modal separation, detection range Limited and other problems, to achieve the effect of convenient and quick defect detection and location, simple and practical method, and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

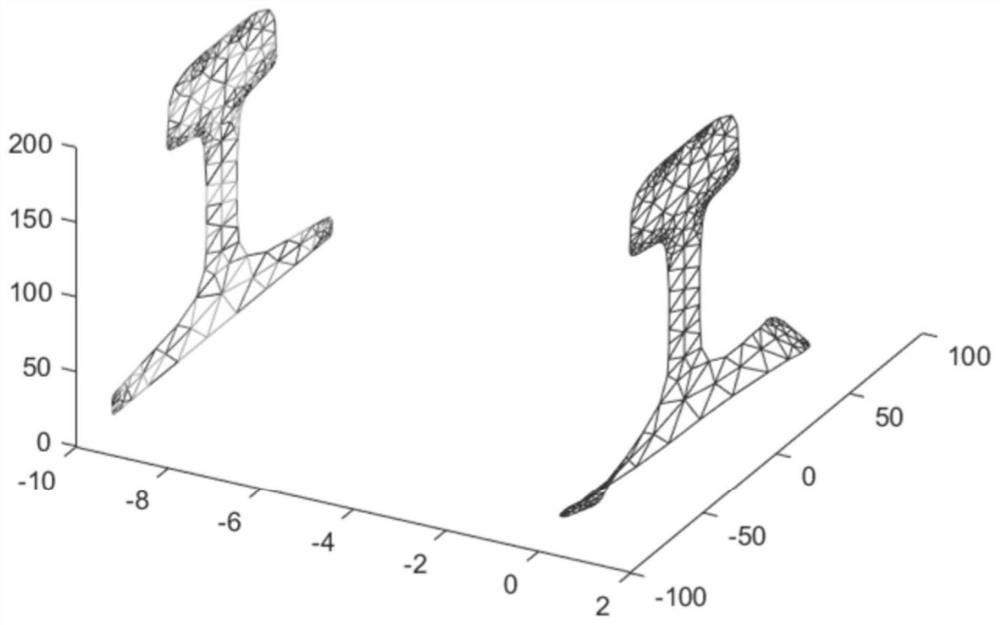

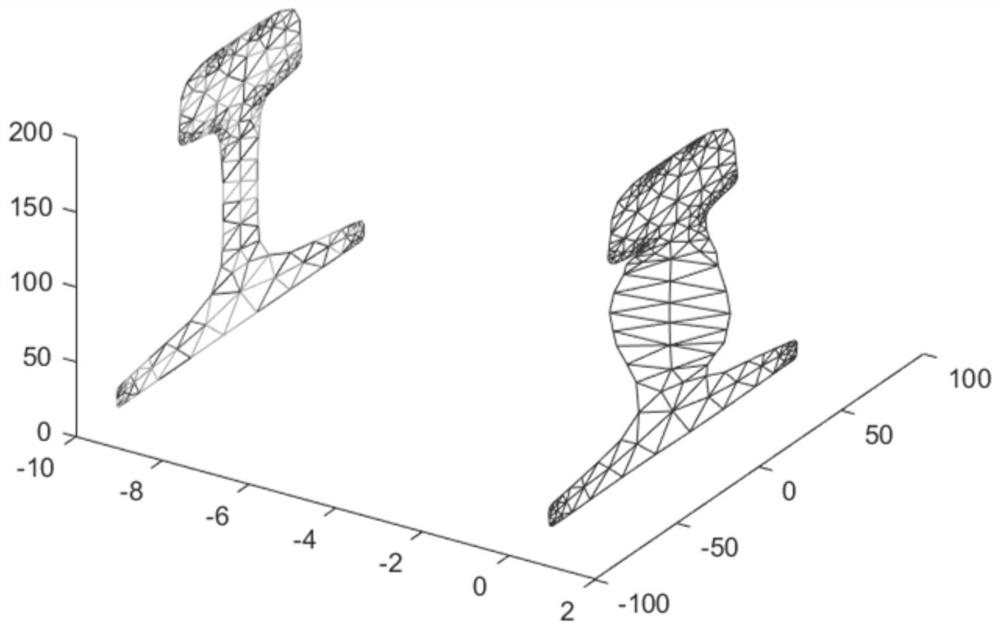

[0038] In the present invention, the seamless steel rail has the characteristics of very long rails. When laying, according to the local temperature of the laying place, select the appropriate temperature to fix the steel rail. At this time, the internal concentrated stress of the steel rail is zero, and this laying temperature is called to lock the rail temperature.

[0039] When studying the relationship between ultrasonic guided wave attenuation and rail temperature, it is necessary to obtain the vibration amplitudes of ultrasonic guided waves at different rail temperatures. You can choose the SGW-II digital rail thermometer strategy for the rail temperature. It uses a magnetic steel adsorption sensor probe, which can be easily adsorbed on any part of the rail. The temperature measurement range is -40 degrees Celsius to 70 degrees Celsius. The basic error of temperature measurement is ±1 degree Celsius, LCD resolution is 0.1 degree Celsius. Digital rail thermometers can al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com