Hydraulic automatic centering, positioning and clamping device

A positioning and clamping, automatic technology, applied in the field of parts positioning and clamping devices, can solve the problems of insufficient machining allowance on one side of the part, uneven machining allowance, difficulty in automation, etc., to achieve automatic control of clamping action and ensure connection Accuracy and reliability, the effect of realizing automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below with reference to the embodiments of the accompanying drawings.

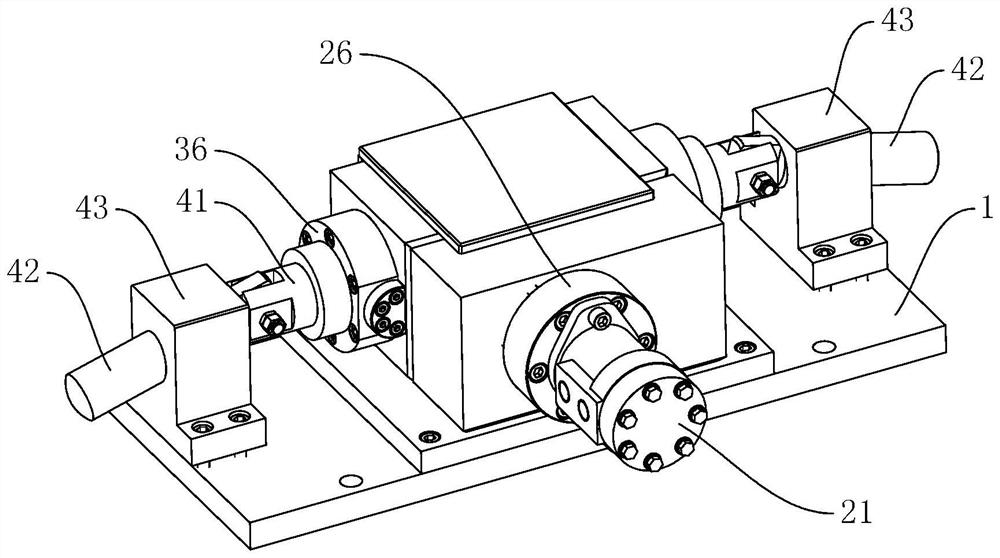

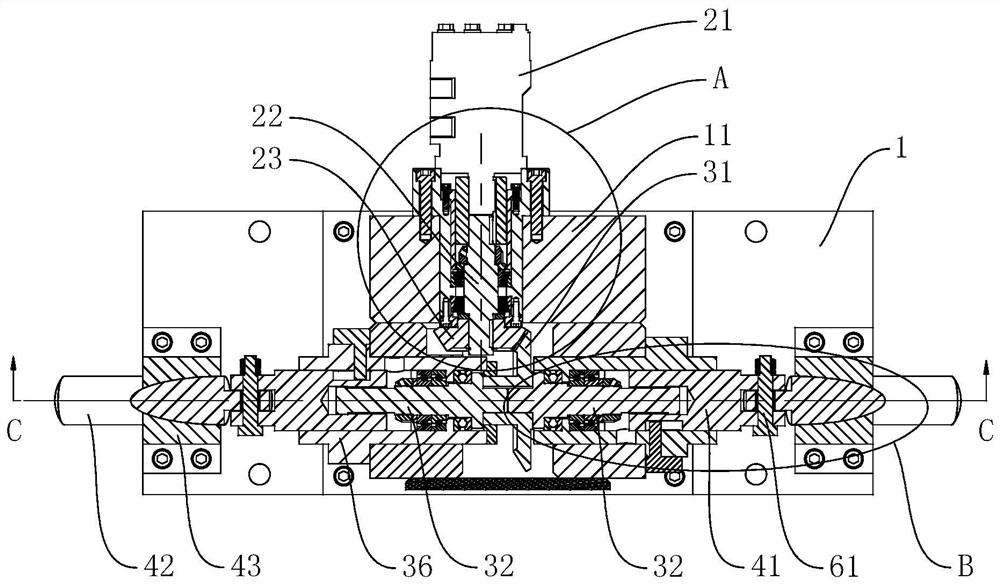

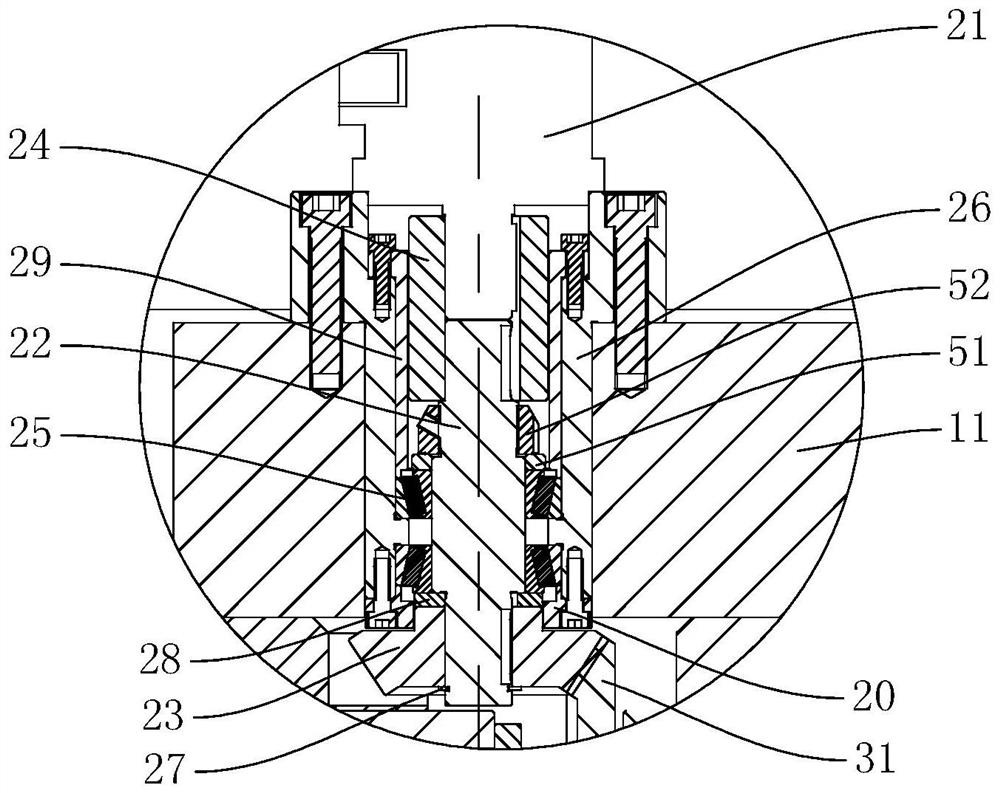

[0022] The hydraulic automatic centering and positioning clamping device of the embodiment, such as Figure 1~Figure 5 As shown, it includes a bottom plate 1, a driving mechanism, a central positioning mechanism and a jacking mechanism. The driving mechanism includes a hydraulic motor 21, an input shaft 22 and a first bevel gear 23. The two ends of the input shaft 22 are respectively connected with the output end of the hydraulic motor 21. It is coaxially and fixedly connected with the first bevel gear 23. The centring positioning mechanism includes a second bevel gear 31 and two centring positioning units. The second bevel gear 31 meshes with the first bevel gear 23. Each centring positioning unit includes a An output shaft 32, the output shafts 32 of the two central positioning units are symmetrically arranged and coaxially fixed on both si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com