Device, method and system for producing hydrogen by electrolyzing water

A hydrogen production device and electrolyzed water technology, applied in the direction of electrolysis components, electrolysis process, cells, etc., can solve the problems of equipment shutdown, high cost, unstable output current harmonics, etc., and achieve the effect of voltage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific implementations of the embodiments of the present invention will be described in detail below with reference to the accompanying drawings. It should be understood that the specific embodiments described herein are only used to illustrate and explain the embodiments of the present invention, and are not used to limit the embodiments of the present invention.

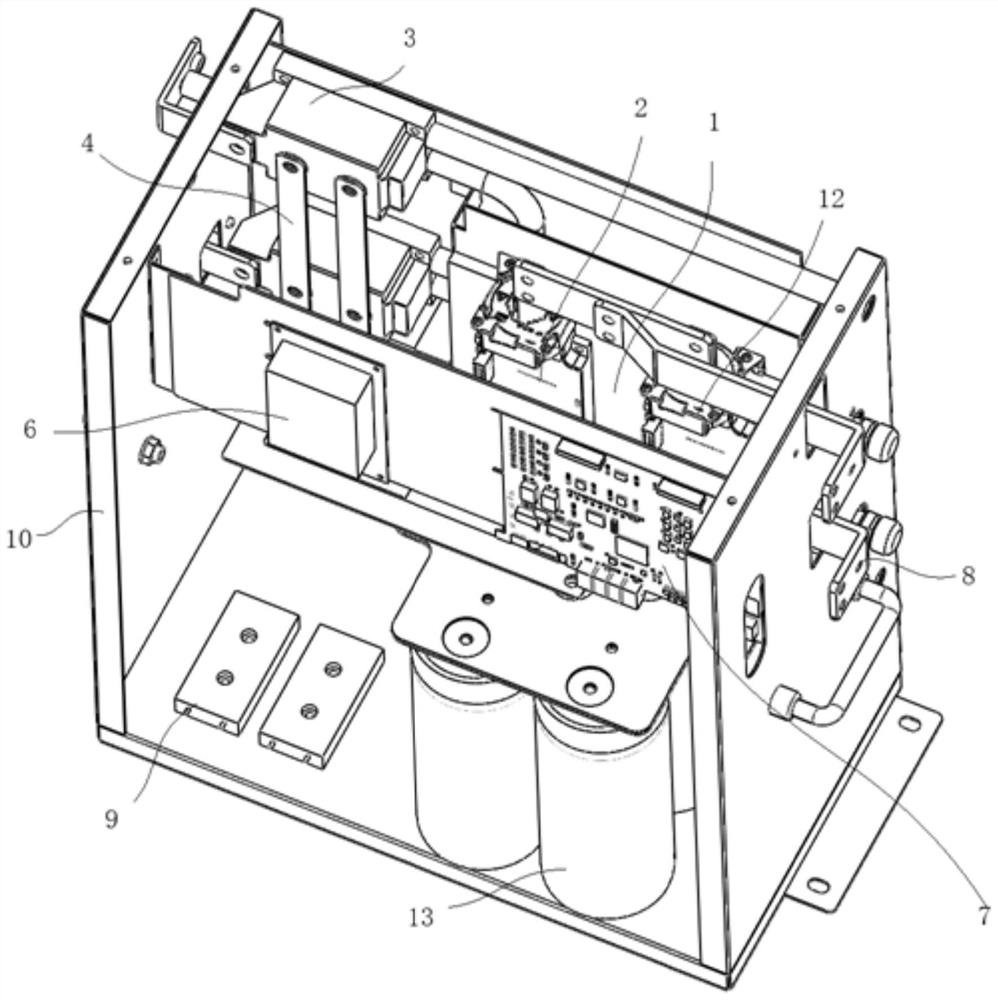

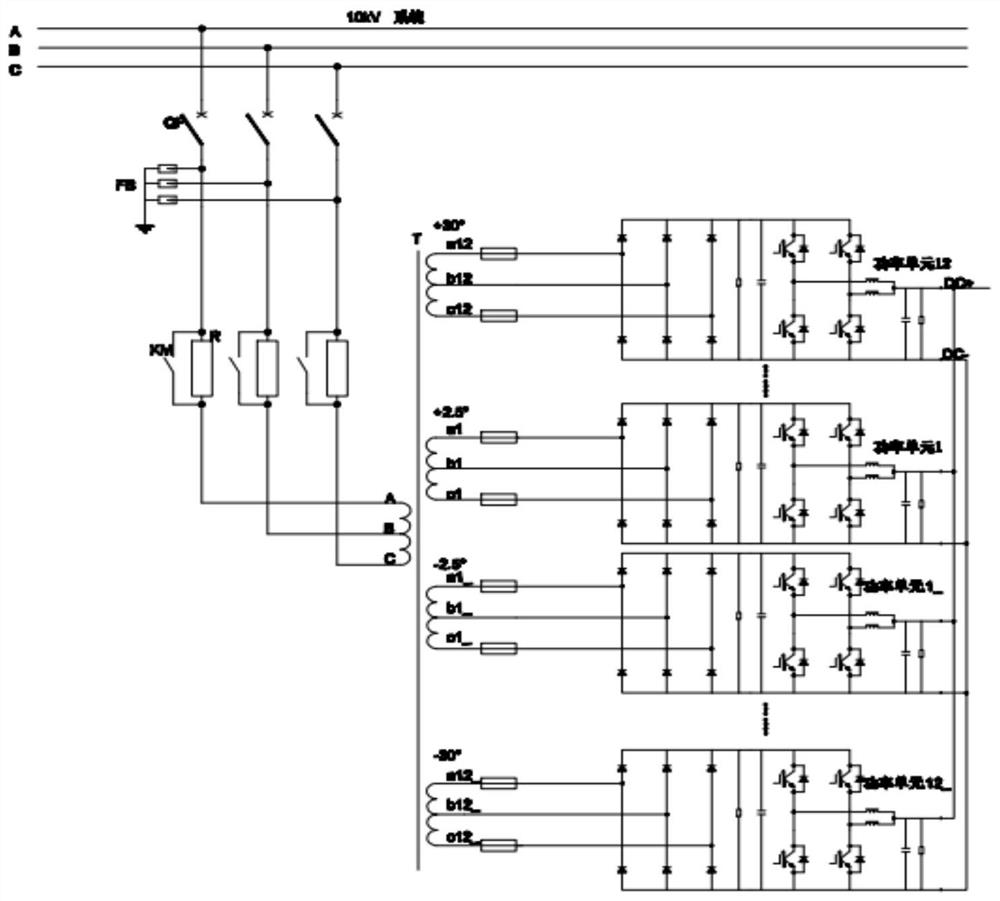

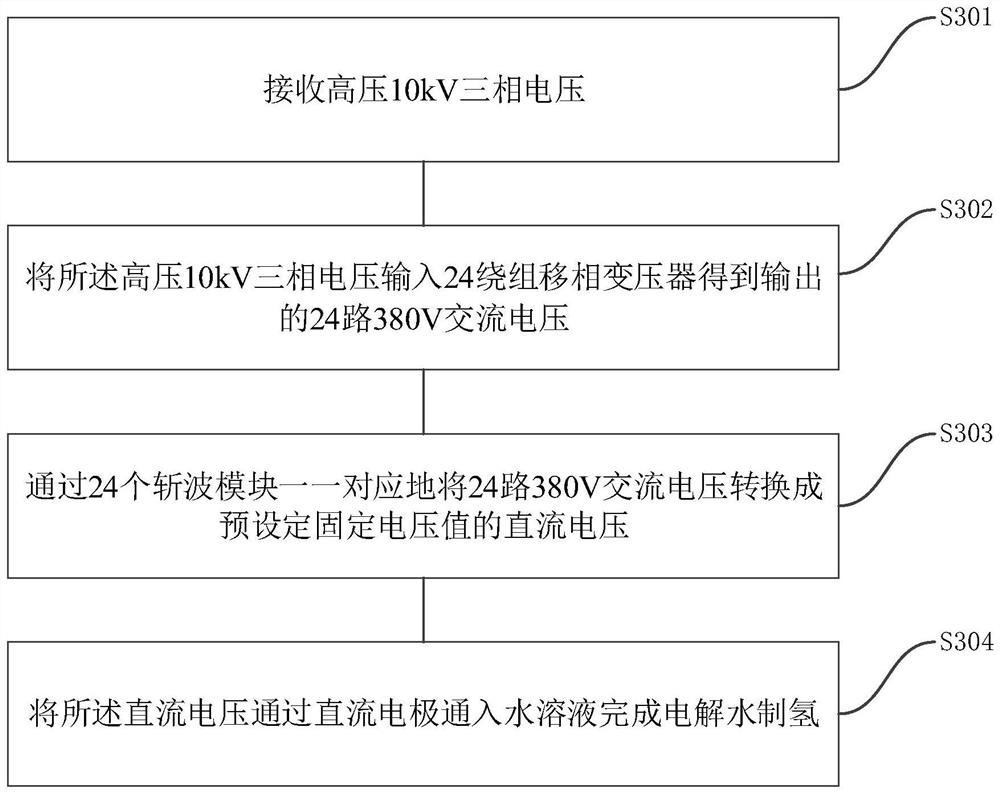

[0035] figure 1 is a schematic structural diagram of a chopper power module of the present invention, Figure 4 is a schematic diagram of the structure from another angle, such as figure 1 As shown, the chopper power module includes a unit casing 10 and 24 chopper modules installed inside the unit casing 10; wherein, the chopper modules are used for 24 channels of AC from a three-phase power supply. The voltage is converted into a DC voltage with a preset fixed voltage value in a one-to-one correspondence, so that the DC electrode electrically connected to the output end of the chopper module and pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com