Automatic control method for operating robot to break lead

A technology for robots and wire cutting, which is applied in the field of operating robots and can solve the problem of inability to effectively cut wires of different specifications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

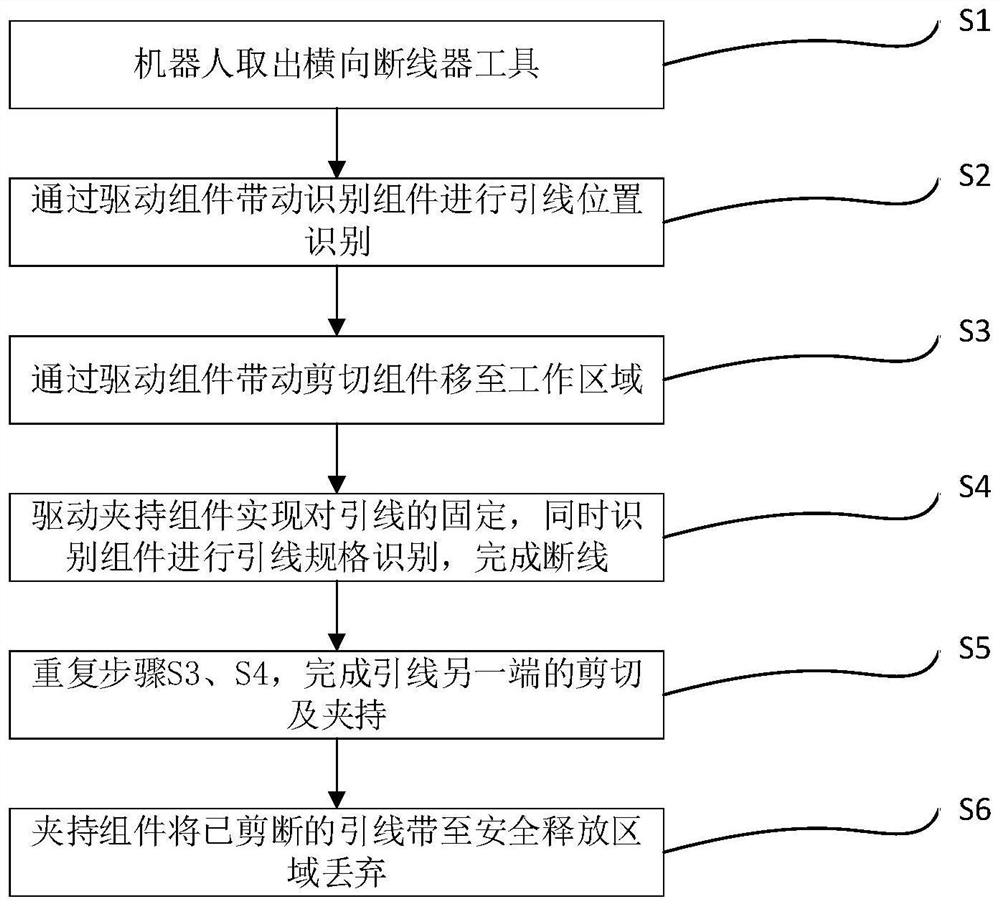

[0033] Embodiment: A kind of automatic control method for operating the robot to break the lead wire of this embodiment, such as figure 1 shown, including the following steps:

[0034] S1 robot takes out the transverse wire breaker tool;

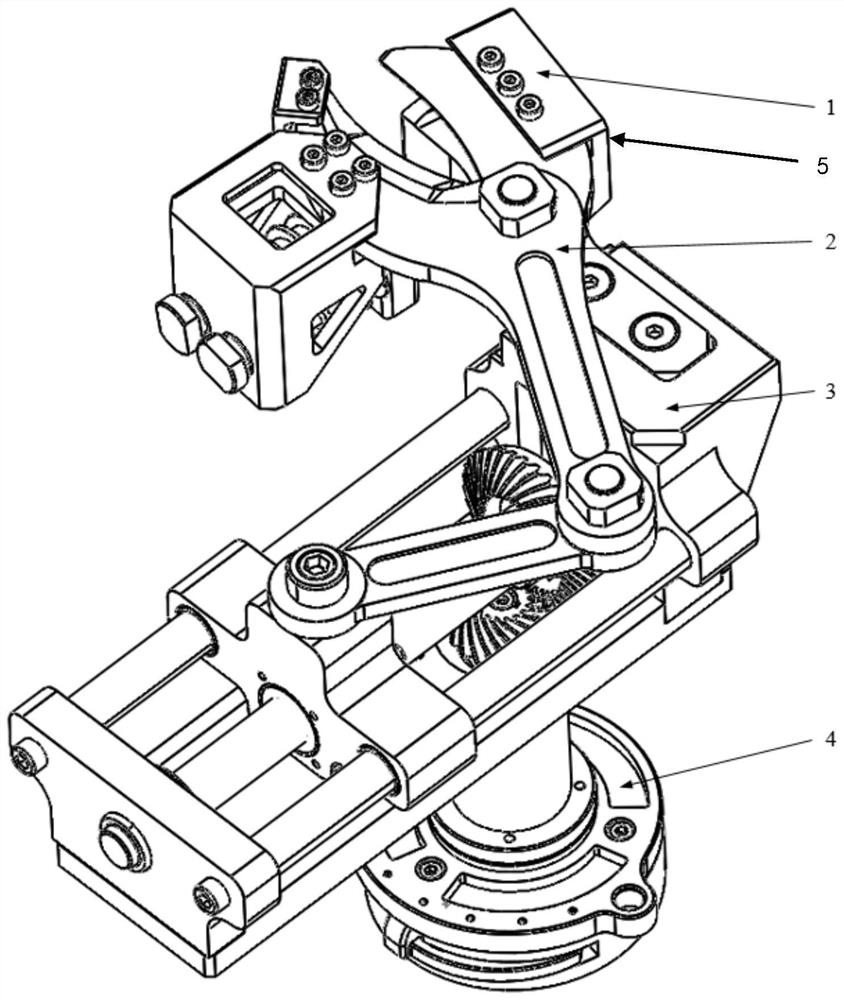

[0035] S2 drives the identification assembly 5 through the drive assembly 3 to identify the lead position;

[0036] S3 drives the shearing component 2 to move to the working area through the driving component 3, which specifically includes:

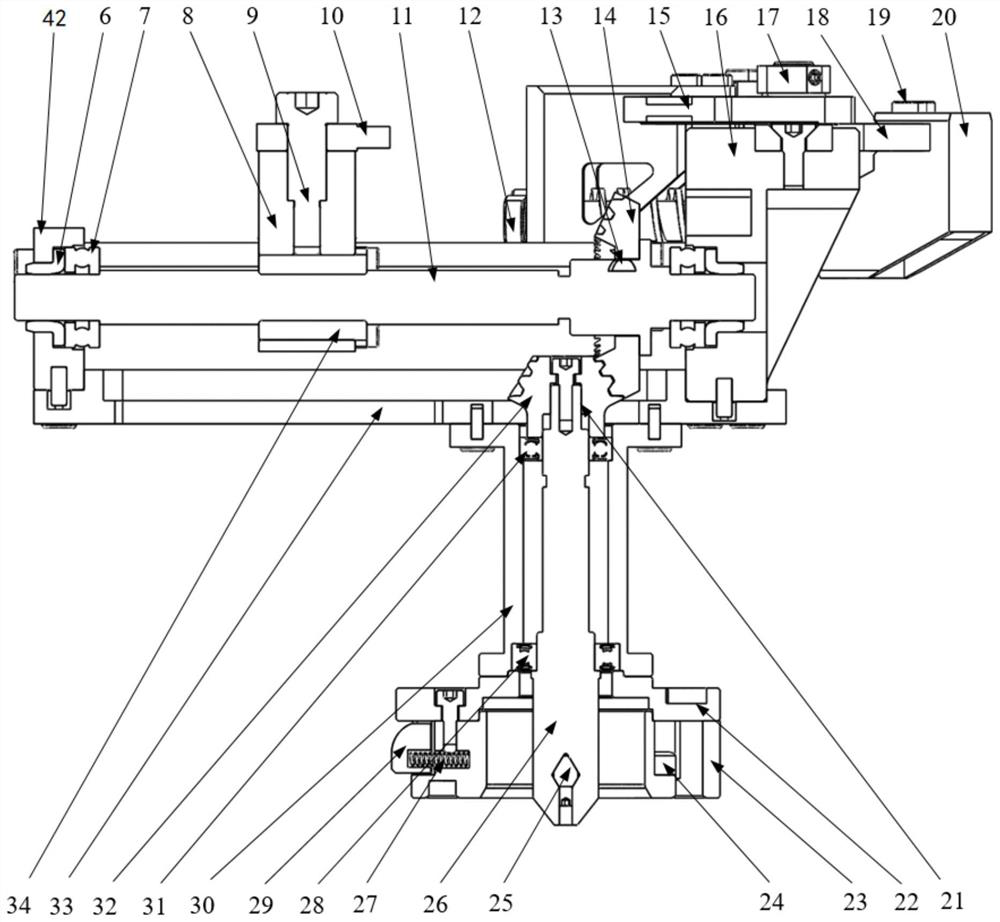

[0037] S3.1 drives the transmission shaft 26 to reverse, and drives the connecting rod 10 and the movable knife 15 in the shearing assembly 2 to move through the driving assembly 3, so that the movable knife 15 moves to the maximum opening limit;

[0038] S3.2 Deliver the horizontal wire breaker tool to the operation area and compare the position of the thread trimmer;

[0039] S3.3 After the thread trimming position is determined, the manipulator moves to make the horizontal thread breaker gradually...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com