Burner capable of adapting to various gas fuels

A technology of gas fuel and combustion chamber, which is applied in the direction of gas fuel burners, burners, combustion chambers, etc., and can solve the problems of being unable to adapt to fuels with different calorific values

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

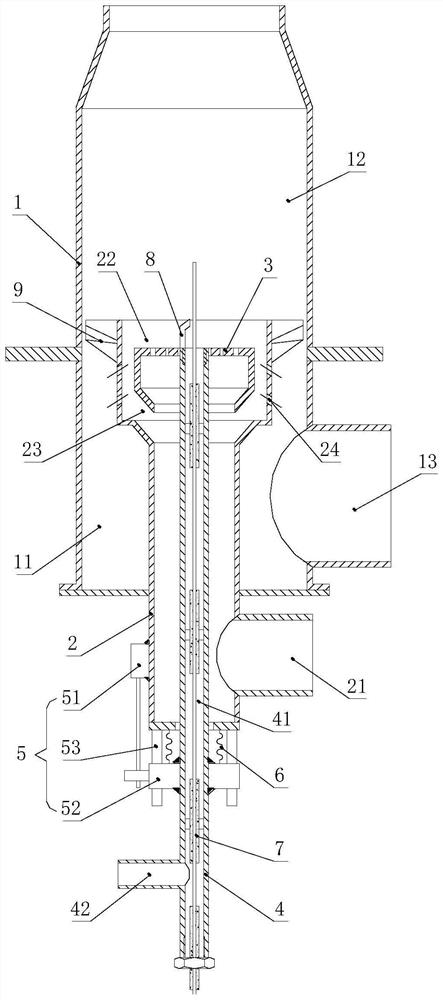

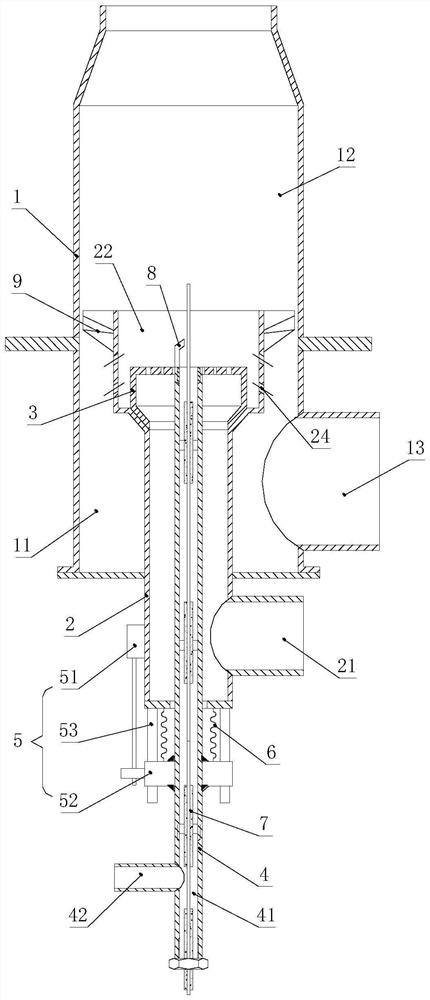

[0029] combined with figure 1 , this embodiment provides a burner that can adapt to a variety of gas fuels, including a casing 1 and a gas supply pipe 2, the casing 1 is provided with an intake chamber 11 and a combustion chamber 12 at both ends, and the intake The chamber 11 is provided with a gas-assisting interface 13, and both ends of the gas supply pipe 2 are respectively provided with a gas interface 21 and a nozzle cavity 22; the end of the gas supply pipe 2 with the nozzle cavity 22 is located in the casing 1, and the The nozzle chamber 22 is connected to the combustion chamber 12; the nozzle chamber 22 is used for accommodating the gas nozzle 3, and a gas flow channel 23 is provided between the gas nozzle 3 and the side wall of the nozzle chamber 22, and the gas flow channel The effective flow area of 23 is adjustable.

[0030] It can be understood that, the effective flow area of the gas flow channel 23 can be adjusted in various ways. The size of the gap betwe...

Embodiment 2

[0049] This embodiment provides a burner that can adapt to a variety of gas fuels. Based on the structure and principle described in Embodiment 1, the nozzle chamber 22 is communicated with the intake chamber 11 through a premixing channel 24, so that the gas During combustion, a small part of the auxiliary gas is injected into the nozzle cavity 22 through the premixing channel 24 on the gas supply pipe 2 to be premixed with the fuel gas, which can improve the stability of the flame.

Embodiment 3

[0051] This embodiment provides a burner that can adapt to various gas fuels. Based on the structure and principle described in Embodiment 1 or Embodiment 2, the gas supply pipe 2 is located at the outer periphery of one end of the combustion chamber 12 . The flow vane 9 is used to make the oxidant gas and the fuel gas fully mixed through the swirling flow vane 9 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com