Novel soft and smooth silicone oil for polyester and preparation method of novel soft and smooth silicone oil

A polyester and silicone oil technology, applied in fiber types, textiles and papermaking, fiber processing, etc., can solve problems such as poor hand feel and polyester fabrics that are not soft and slippery, and achieve the effect of improving soft and slippery performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

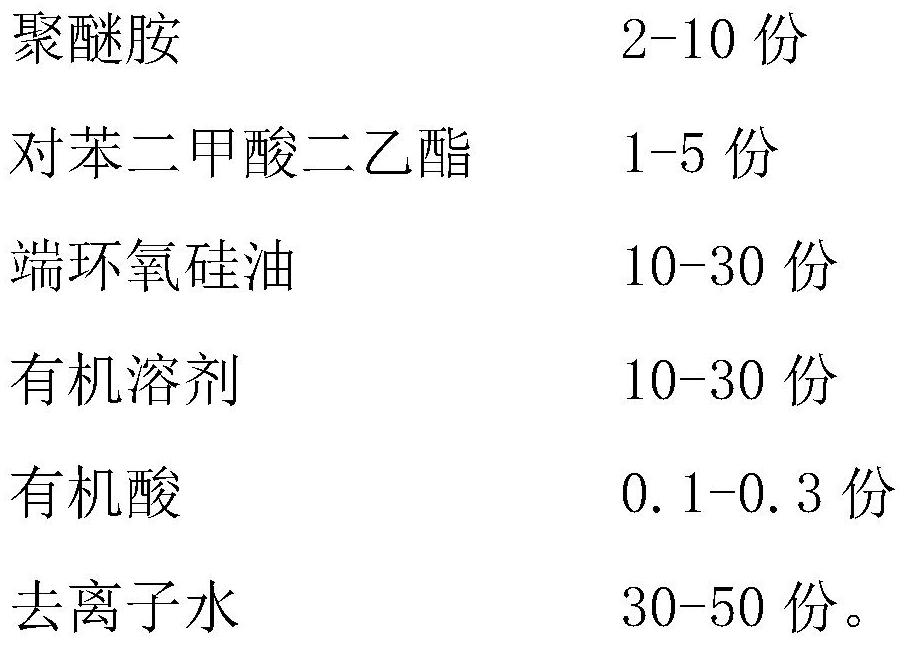

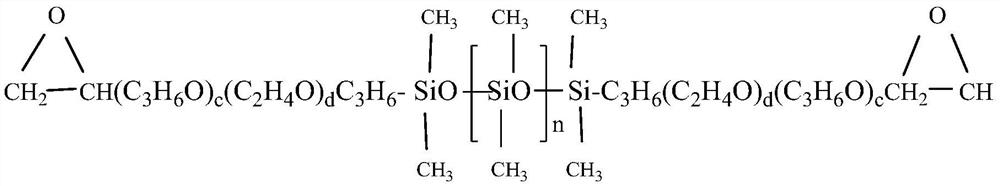

[0027] The raw materials of the following metered weights are provided: polyether amine with a molecular weight of 600: 4.6 parts, diethyl terephthalate: 2 parts, epoxy-terminated polyether silicone oil with a molecular weight of 13000: 26.8 parts, ethylene glycol monobutyl ether: 28 parts , glacial acetic acid: 0.5 parts, deionized water 32.3 parts.

[0028] The specific preparation process of the soft and slippery silicone oil for polyester involved in the present invention is as follows:

[0029] (1) Add polyetheramine and diethyl terephthalate to the reactor, heat to 160°C, react for 5 hours and remove ethanol in a vacuum;

[0030] (2) Add epoxy-terminated polyether silicone oil and organic solvent to the reaction vessel, react at 100°C for 15 hours, cool to 50°C, and proceed to the next step;

[0031] (3) Slowly add 10 parts of deionized water, stir for 10 minutes, then mix the organic acid and 10 parts of deionized water evenly, and slowly add;

[0032] (4) Slowly add ...

Embodiment 2

[0034] The raw material of following measurement weight is provided: the polyether amine of molecular weight 600: 3.8 parts, diethyl terephthalate: 1.4 parts, the end epoxy polyether silicone oil of molecular weight 10000: 20 parts, ethylene glycol butyl ether: 25 parts, Glacial acetic acid: 0.5 parts, 49.5 parts of deionized water.

[0035] The specific preparation process of the soft and slippery silicone oil for polyester involved in the present invention is as follows:

[0036] (1) Add polyetheramine and diethyl terephthalate to the reactor, heat to 160°C, react for 6 hours and remove ethanol in a vacuum;

[0037] (2) Add epoxy-terminated polyether silicone oil and solvent to the reaction vessel, react at 100°C for 18 hours, cool to 50°C, and proceed to the next step;

[0038] (3) Slowly add 10 parts of deionized water, stir for 10 minutes, then mix the organic acid and 10 parts of deionized water evenly, and slowly add;

[0039] (4) Slowly add the remaining deionized wa...

Embodiment 3

[0041] The raw materials of the following metered weights are provided: polyether amine with a molecular weight of 900: 5.5 parts, diethyl terephthalate: 1.7 parts, epoxy-terminated polyether silicone oil with a molecular weight of 8000: 30.3 parts, butyl glycol ether: 30 parts, Glacial acetic acid: 0.5 parts, deionized water 32.0 parts.

[0042] The specific preparation process of the soft and slippery silicone oil for polyester involved in the present invention is as follows:

[0043] (1) Add polyetheramine and diethyl terephthalate to the reactor, heat to 160°C, react for 6 hours and remove ethanol in a vacuum;

[0044] (2) Add epoxy-terminated polyether silicone oil and solvent into the reaction vessel, react at 100°C for 24 hours, cool to 50°C, and proceed to the next step.

[0045] (3) Slowly add 10 parts of deionized water, stir for 10 minutes, then mix the organic acid and 10 parts of deionized water evenly, and slowly add;

[0046] (4) Slowly add the remaining deion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com