Space on-orbit centrifugal machine stator supporting assembly and centrifugal machine

A technology for supporting components and machine stators, applied to motor vehicles, aerospace equipment, space navigation equipment, etc., can solve problems such as complex support structures and difficulties in effectively supporting centrifuges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

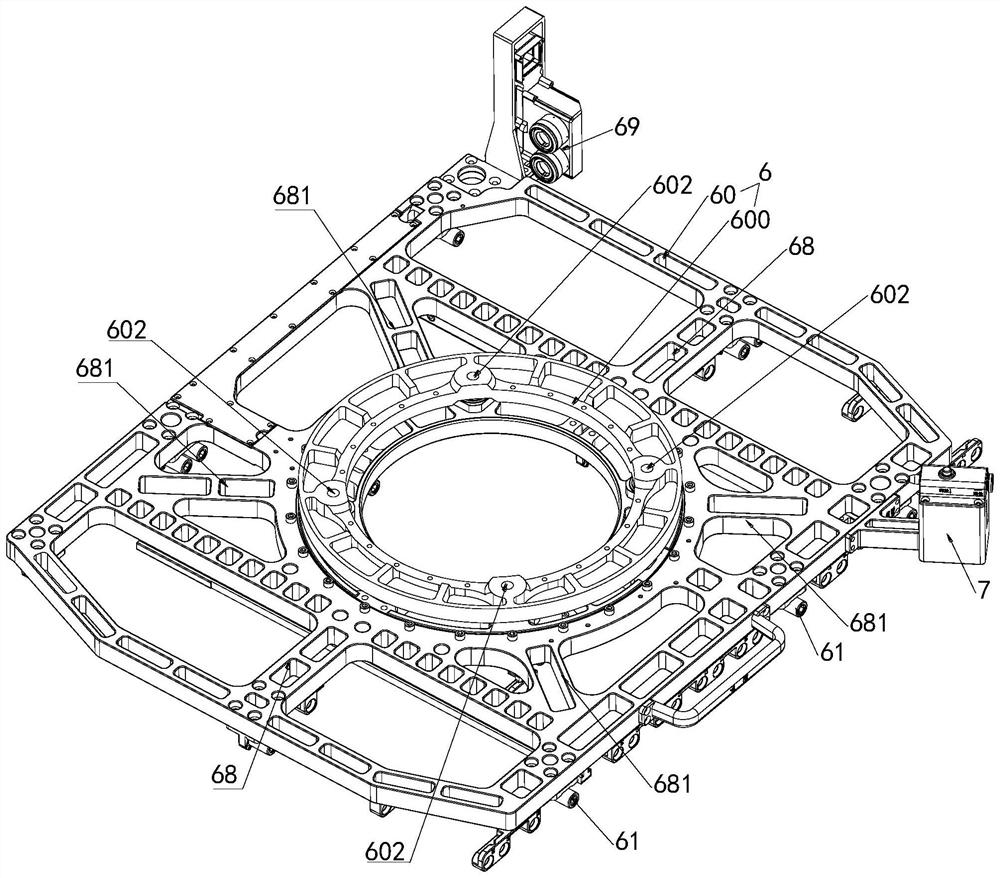

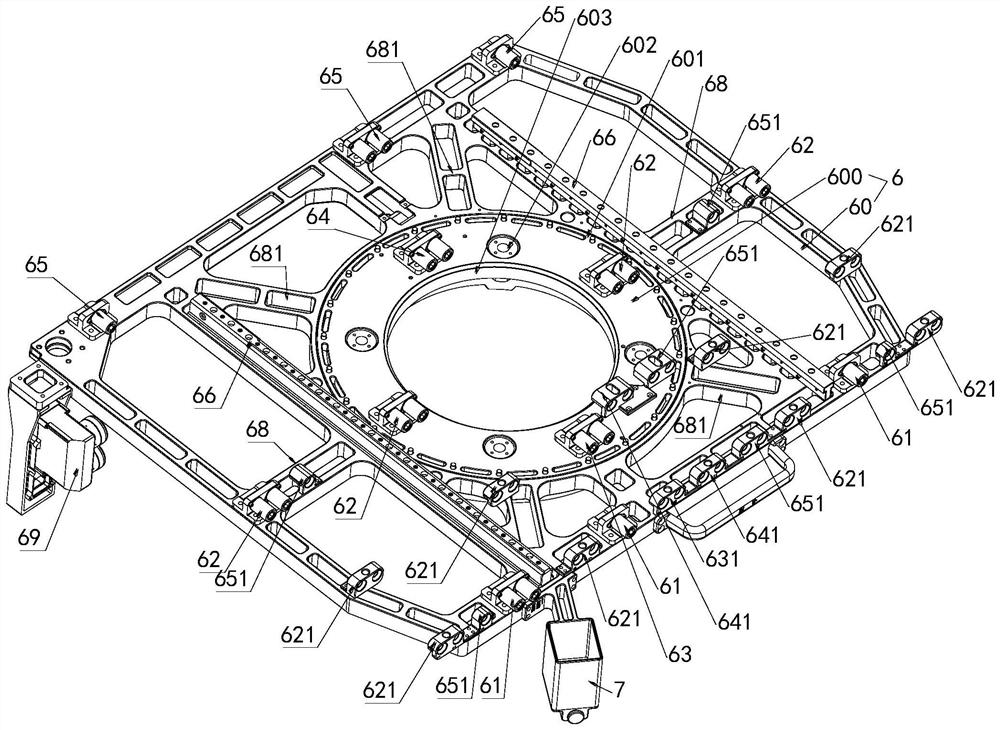

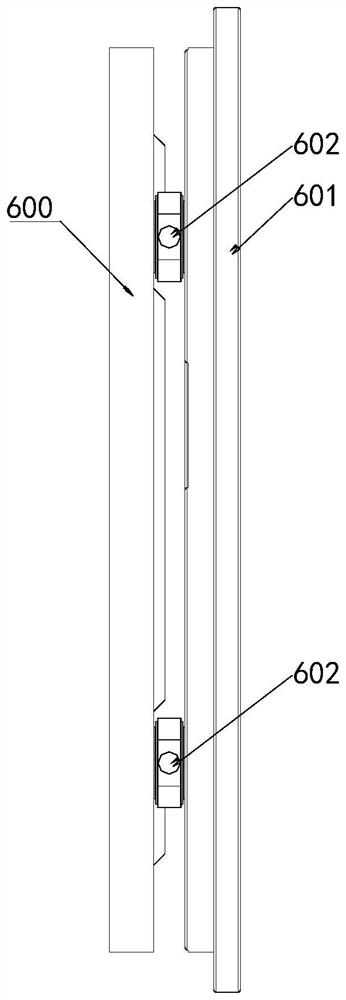

[0049] like Figure 1 to Figure 9 As shown, a space-on-orbit centrifuge stator support assembly in this embodiment includes a support frame 6, and the front end, middle and rear end of one side of the support frame 6 are respectively provided with front end connecting bolts 61, middle connecting bolts and rear end connecting bolts 61. The end connecting bolt 65 is provided with a first guide seat on one side of the support frame 6 corresponding to the front side of the middle connecting bolt, and a second guide seat is provided on one side of the support frame 6 corresponding to the front side of the rear end connecting bolt 65 651; one side surface of the support frame 6 is provided with a guide rail 66 arranged in the front-rear direction, and a stator assembly hole 67 is provided in the middle of the other side surface of the support frame 6.

[0050] like figure 1 and figure 2 As shown, the middle connecting bolts in this embodiment include middle connecting bolts 62, m...

Embodiment 2

[0077] like Figure 10 As shown, a centrifuge in this embodiment includes the space-on-orbit centrifuge stator support assembly described in Embodiment 1, and also includes a turntable 4 and a drive device 5 , and the stator of the drive device is assembled on the support frame 6 In the stator mounting hole 67 in the middle of the other side of the , that is, it is mounted in the stator mounting hole 67 of the balance measuring force table, and the turntable 4 is mounted on the rotor of the driving device.

[0078] In the centrifuge of this embodiment, the supporting assembly can be used to effectively and stably support the driving device, and the components such as the driving device and the turntable can be stably and compactly assembled on the inner wall of the cabinet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com