Coaxial electric drive axle assembly with self-locking and disengaging functions and working method

A coaxial, electric drive technology, applied in axles, transportation and packaging, control devices, etc., can solve the problems of disengagement of the integral bridge without electric drive, lack of all-terrain driving, unfavorable battery layout, etc., to achieve favorable Lightweight design, good vehicle space utilization, and the effect of reducing drag torque and back electromotive force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

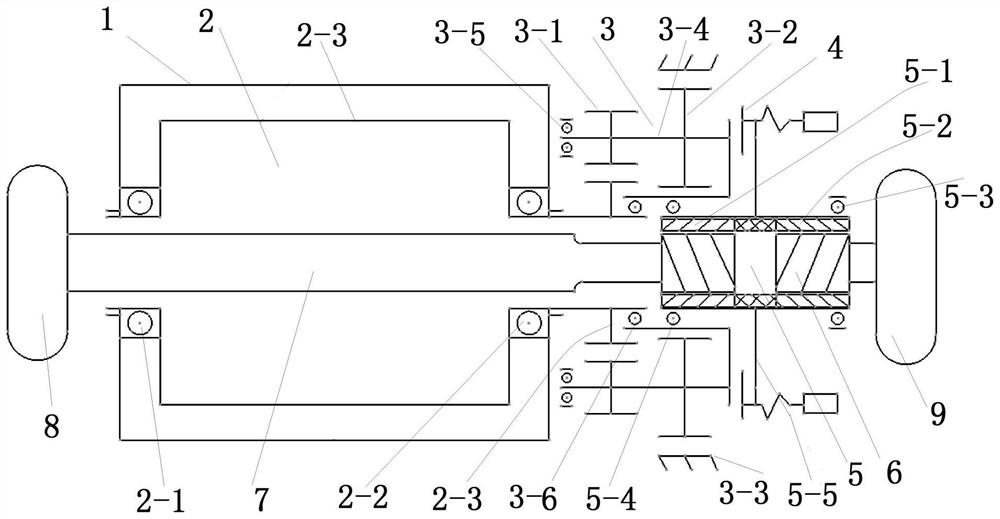

[0024] refer to figure 1 , a coaxial electric drive axle assembly with self-locking and disengaging functions, including a stator assembly 1, a rotor assembly 2, an axle housing (not shown), a planetary gear assembly 3, an electromagnetic clutch 4 , Self-locking differential assembly 5, right half shaft 6, left half shaft 7, the rotor assembly 2 has an axial inner hole, and the axial inner hole of the rotor assembly 2 is sleeved on the left half shaft 7 , the planetary gear assembly 3 includes a sun gear 2-3, a planetary pinion 3-1, a planetary large gear 3-2, a ring gear 3-3, and a planet carrier 3-4. The sun gear 2-3 is fixedly arranged At the right end of the rotor assembly 2, the planetary pinion 3-1 and the planetary gear 3-2 are mounted on the planet carrier 3-4, and the planetary pinion 3-1 and the planetary gear 3-2 are coaxially fixed , the planetary pinion 3-1 meshes with the sun gear 2-3, the planetary gear 3-2 meshes with the internal teeth of the ring gear 3-3, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com