Vehicle-mounted camera cleaning device based on small swing brush

A cleaning device and camera technology, applied in the field of vehicle cameras, can solve problems such as failure to work normally, dirty external cameras, etc., and achieve the effect of simple, stable and efficient structure, and reduce potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

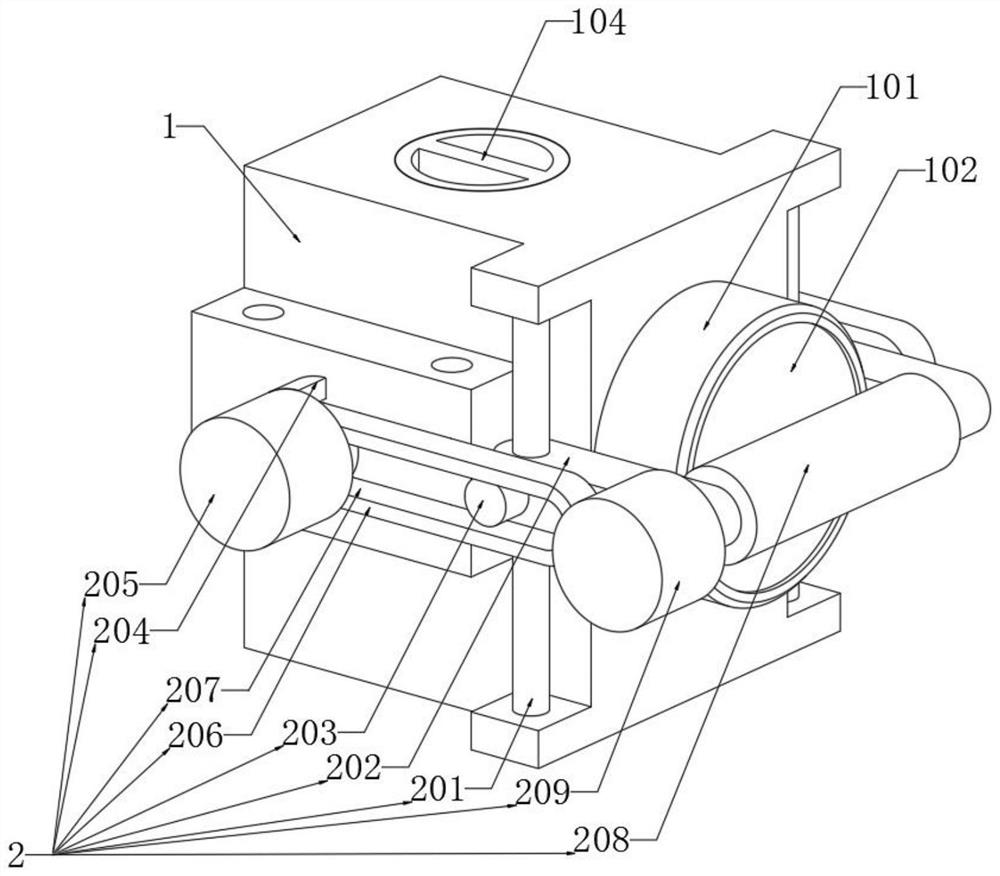

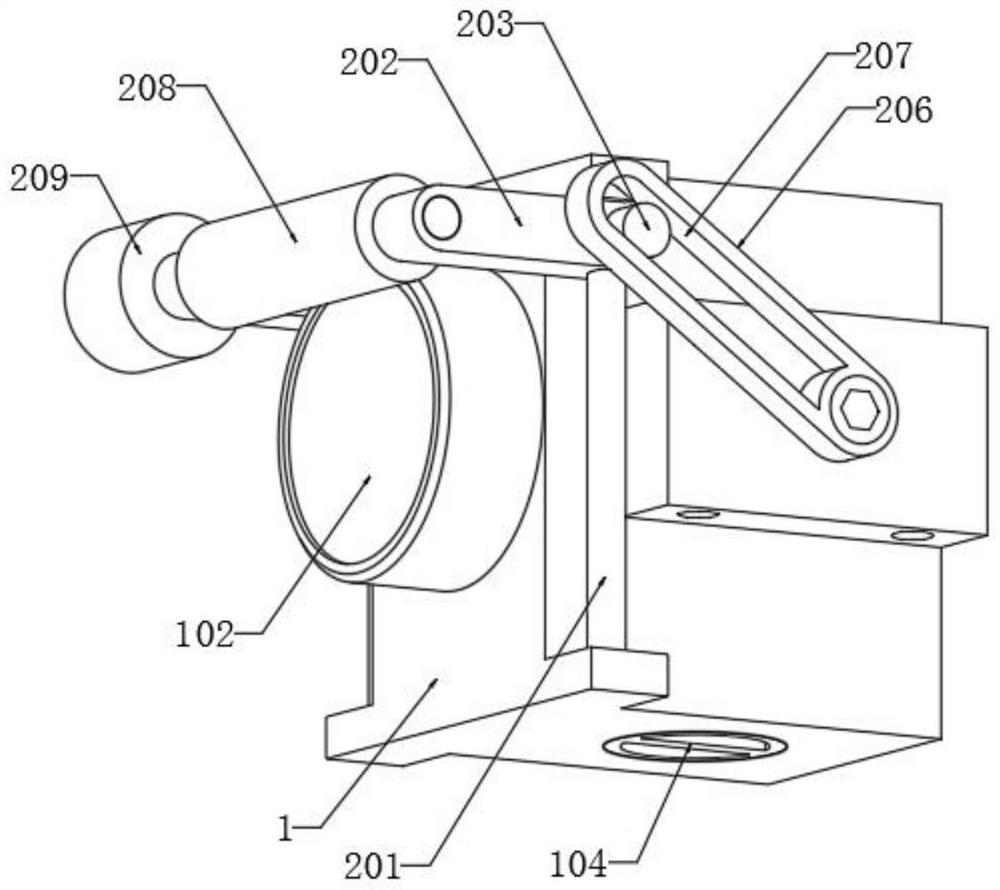

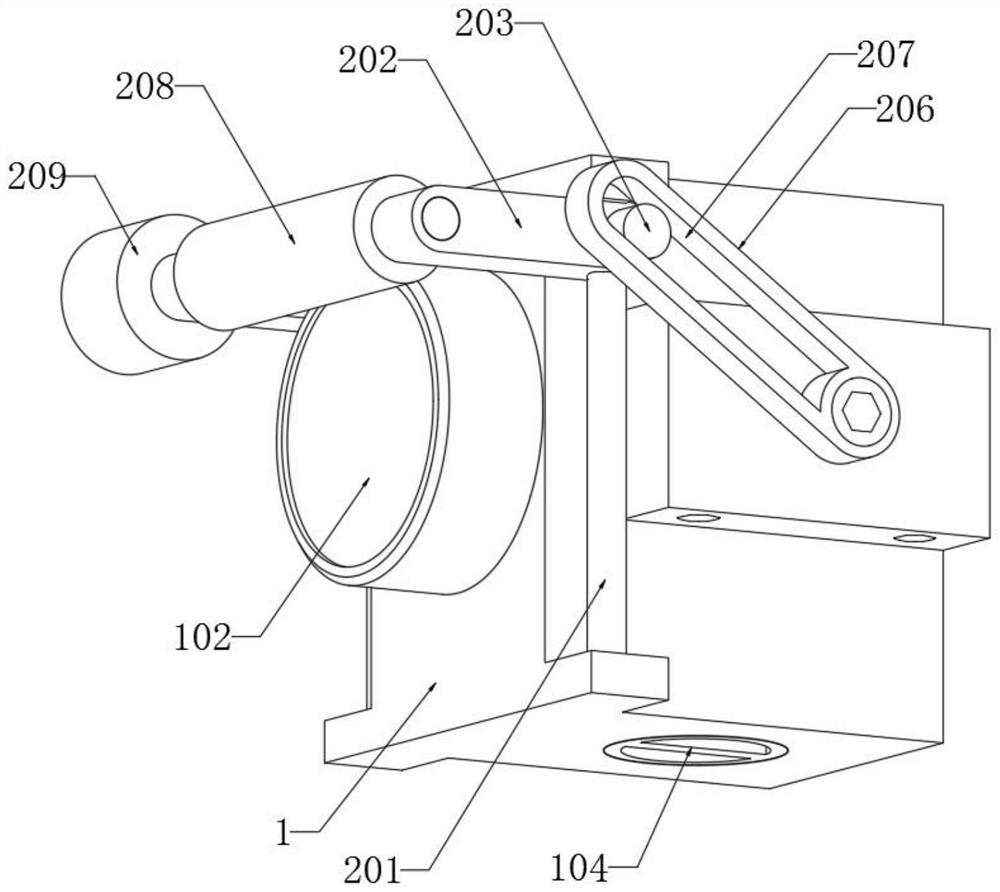

[0037] refer to Figure 1-Figure 8 , a vehicle-mounted camera cleaning device based on a small pendulum brush, comprising a housing 1 and a camera 3, the camera 3 is installed in the housing 1, and the outer wall of the housing 1 is provided with a protective cover 101 and a lens 102 for the camera 3 to shoot, The outer wall of the housing 1 is also installed with a swing brush mechanism 2 for cleaning the lens 102;

[0038] The swing brush mechanism 2 includes a roller brush 208 and a second motor 209 for cleaning the lens 102, and also includes a first motor 205, a connecting rod 206, a guide rod 201 and a slider 202 for driving the roller brush 208 to swing. The guide rods 201 are located on both sides of the protective cover 101 , the slider 202 is slidably connected to the guide rod 201 , and both ends of the roller brush 208 are rotatably connected to the two sets of sliders 202 , and the first motor 205 passes through The bracket 204 is connected to the housing 1, and ...

Embodiment 2

[0047] In Example 1, the first motor 205 drives the roller brush 208 to swing to the obstruction area, starts the second motor 209, and drives the roller brush 208 to rotate to remove the obstruction. The first motor 205 is only responsible for swinging the roller brush 208 to the obstruction area, Instead of directly participating in the cleaning of the obstructions, the second motor 209 drives the roller brush 208 to rotate and clean, which belongs to fixed-point cleaning. The difference between Embodiment 2 and Embodiment 1 is that the second motor 209 controls the roller brush 208 not to rotate, completely The roller brush 208 is driven by the first motor 205 to repeatedly oscillate to erase the obstructions on the surface of the lens 102 . This cleaning method directly cleans the entire lens 102 without calculating the position of the obstruction, which can save CPU computing power.

Embodiment 3

[0049]The difference from Embodiment 1 and Embodiment 2 is that the first motor 205 and the second motor 209 work at the same time, and the roller brush 208 is driven to rotate while wiping the surface of the lens 102. At this time, the cleaning ability of the swing brush mechanism 2 is relatively strong. , the stubborn dirt that is difficult to remove in Example 1 and Example 2 can be removed.

[0050] The working principle of the swing brush mechanism 2 of the device: the device drives the connecting rod 206 to deflect through the first motor 205, and the deflected connecting rod 206 drives the sliding block 202 to slide along the guide rod 201 through the sliding groove 207 and the short column 203, and passes the sliding block 202 The second motor 209 and the roller brush 208 are driven to swing. During this process, the slider 202 is restricted by the guide rod 201 , so that the moving path of the roller brush 208 is always in close contact with the lens 102 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com