Automatic glue applying system for wind power blade production

A technology for wind turbine blades and glue storage, which is applied in the fields of final product manufacturing, climate sustainability, coating, etc., and can solve problems such as early solidification of adhesive glue and low efficiency of manual glue application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

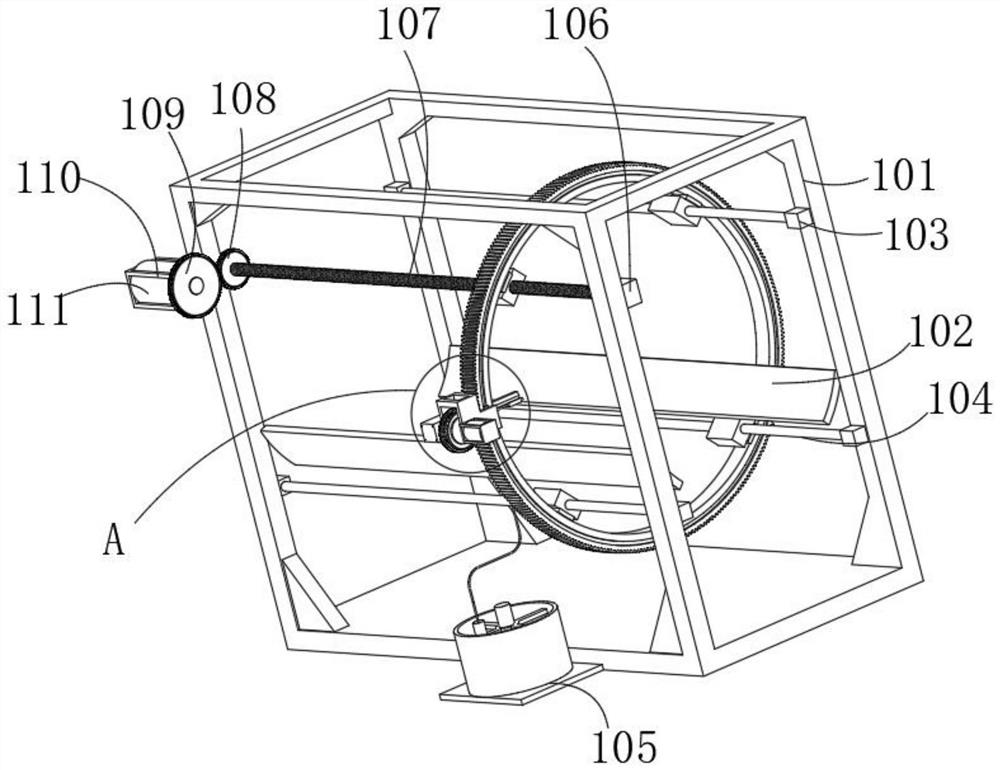

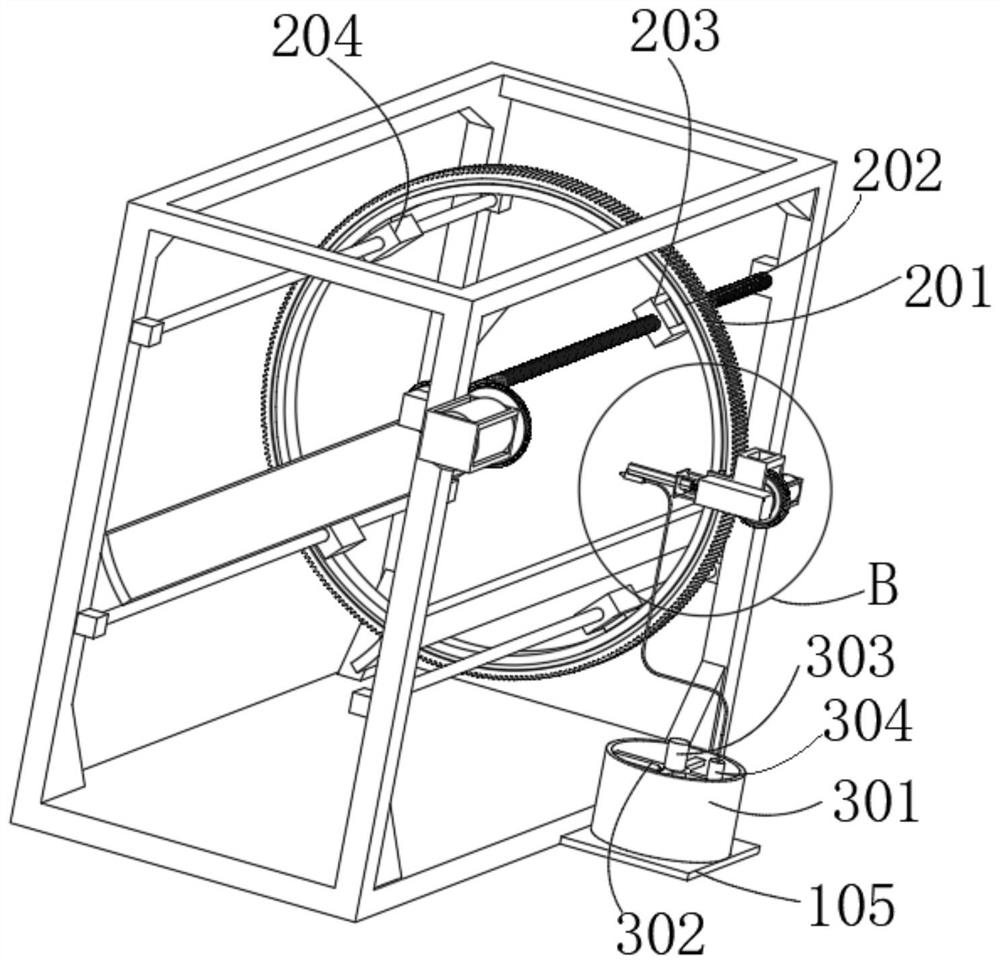

[0029] like Figure 1-6As shown, the embodiment of the present invention provides an automatic glue application system for wind power blade production, which includes a main fixing mechanism 1, a circular driving mechanism 2 and a middle dump glue mechanism 3. The main fixing mechanism 1 is provided with a circular driving mechanism The side part of the fixing mechanism 1 is provided with a middle dumping glue mechanism 3 .

[0030] The main fixing mechanism 1 includes a fixing frame 101 , an arc-shaped stocking plate 102 , a fixing piece 103 , a limit sliding rod 104 , a supporting plate 105 , a fixed bearing 106 , a main driving screw 107 , a lateral driving auxiliary gear 108 , and a lateral driving main gear 109 , The first motor frame 110 and the transverse drive motor 111, the upper and lower middle of the inner rear side wall of the fixed frame 101 and the middle and lower parts of the inner front side wall are fixedly connected to two sets of laterally arranged fixing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com