Air pressure driven cavity type flexible color-changing film and method

A color-changing film, air pressure-driven technology, applied in optical components, instruments, optics, etc., can solve the problems of unstable performance, single color change, slow color change speed, etc., to achieve simple structure and principle, eliminate exposure characteristics, and respond quickly. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

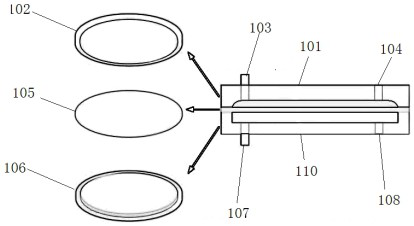

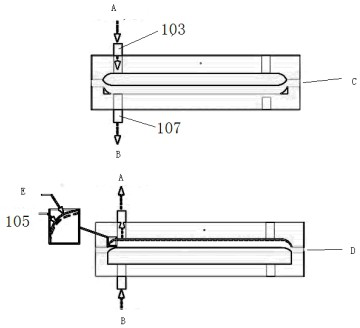

[0034] like figure 1 , 2 , 3, 4, and 5, a pneumatically driven chamber type flexible color-changing film, including an upper PMMA plate 101, a colored liquid chamber 102, an elastic film 105 between the two chambers, a colorless gas chamber 106, Dichroic layer, inter-color PMMA plate, bottom layer, lower layer PMMA plate 110, colorless gas control system device and colored liquid cavity color-changing film device. The colored liquid chamber is connected with the microfluidic control system device; the colored liquid chamber 102 is connected with the elastic film 105 between the two chambers, and the elastic film 105 between the two chambers is in contact with the colorless gas chamber 106. connect.

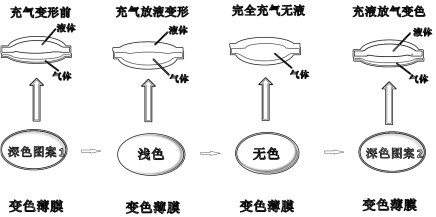

[0035] By adjusting the compressed air gas driving device, the colorless gas is filled into the air cavity of the lower layer of the cavity-type color-changing film, so as to squeeze the deformation of the colored film to complete the color change of the film; the microfluidic d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com