Method for evaluating bonding performance of pavement heating type sealant based on dissipated energy

A technology of bonding performance and sealant, which is applied in the direction of applying stable tension/pressure to test the strength of materials, instruments, complex mathematical operations, etc. The effect of evaluation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

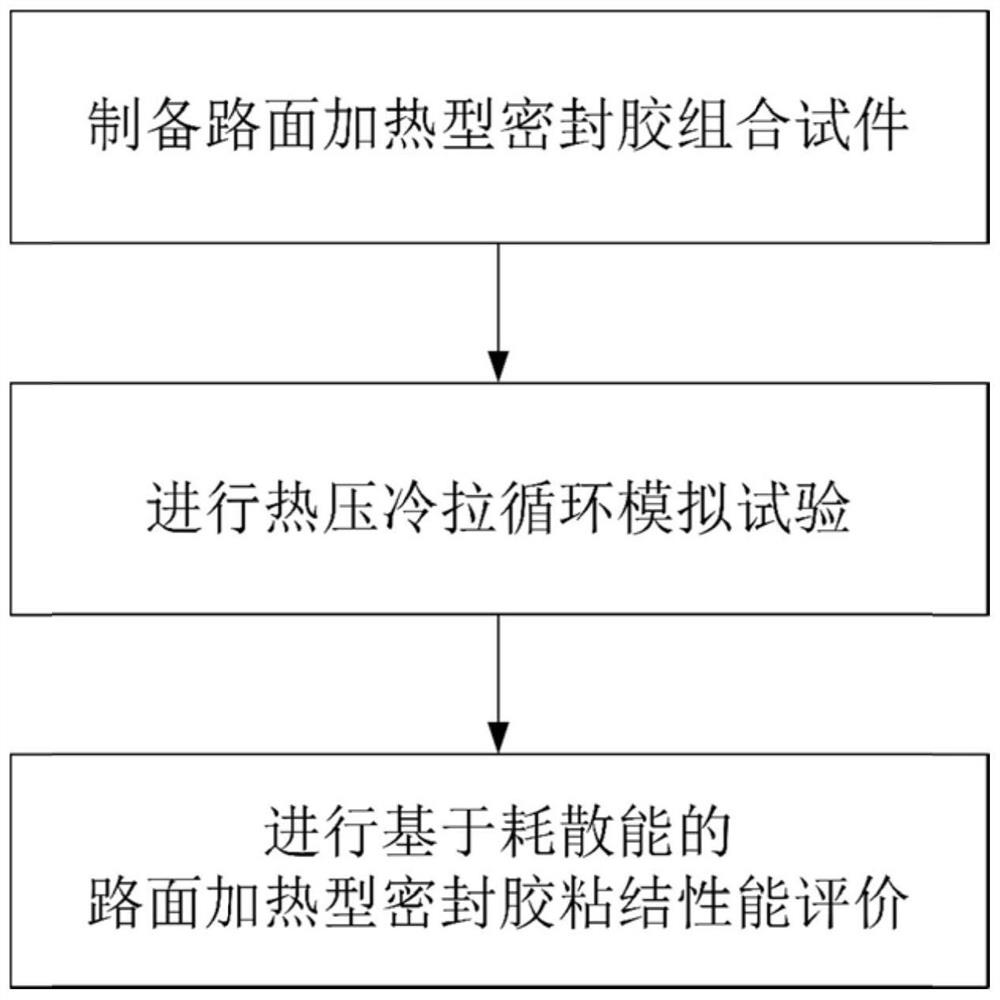

[0052] like figure 1 As shown, the method for evaluating the bonding performance of the road heating type sealant based on dissipated energy of the present invention includes the following steps:

[0053] Step 1. Prepare the pavement heating type sealant composite test piece, which specifically includes the following steps:

[0054] Step 11. Preparation of asphalt mixture test block: cut the asphalt mixture standard rutting test sample with AC-13 gradation to obtain a plurality of block-shaped asphalt mixture test blocks, the size of the asphalt mixture test block is 7cm× 7cm×2cm;

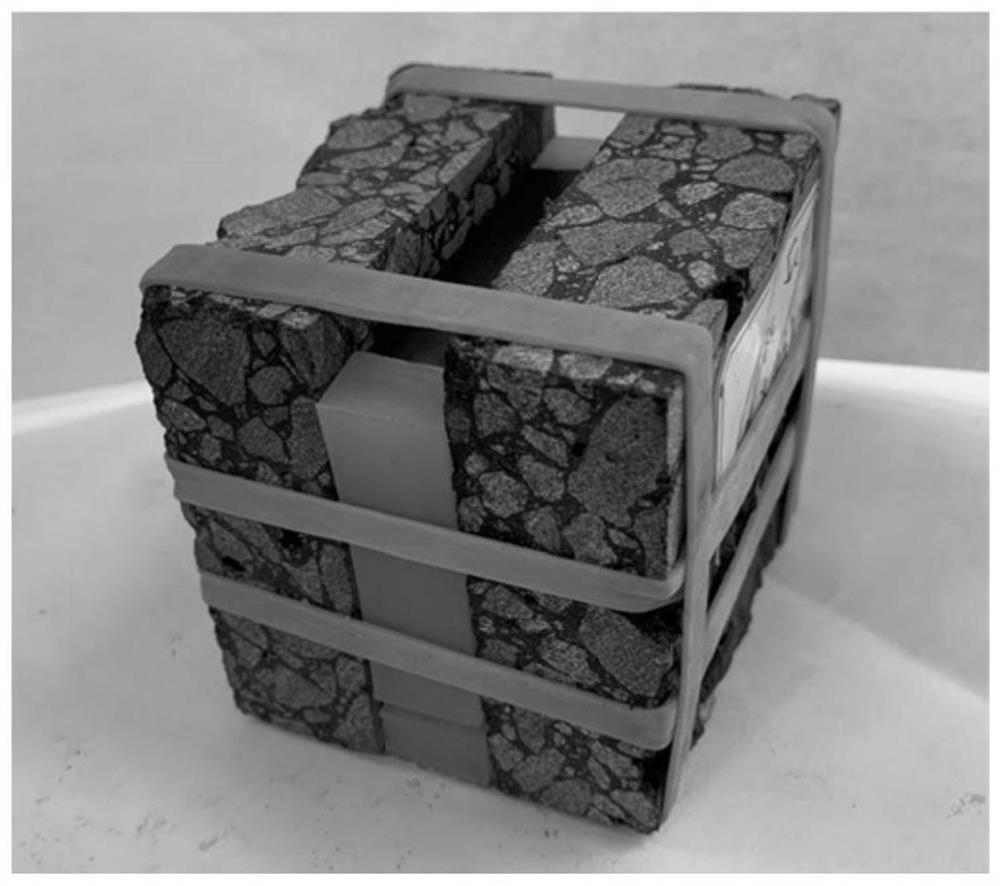

[0055] Step 12. Preparations before the sealant is poured: such as figure 2 As shown, use 3 spacers and 2 block asphalt mixture test blocks to form a 5cm×5cm×1.5cm groove gap, and use 4 rubber belts to fix the test block and spacer block, the spacer bloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com