Hybrid bidirectional driving unmanned mining dump truck chassis

A mining dump truck and unmanned driving technology, which is applied in the direction of electric vehicles, power units, steering rods, etc., can solve the problems of a large number of manpower, increased labor costs, and inconvenient unloading of materials, so as to ensure power and solve the difficulty of turning around. , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

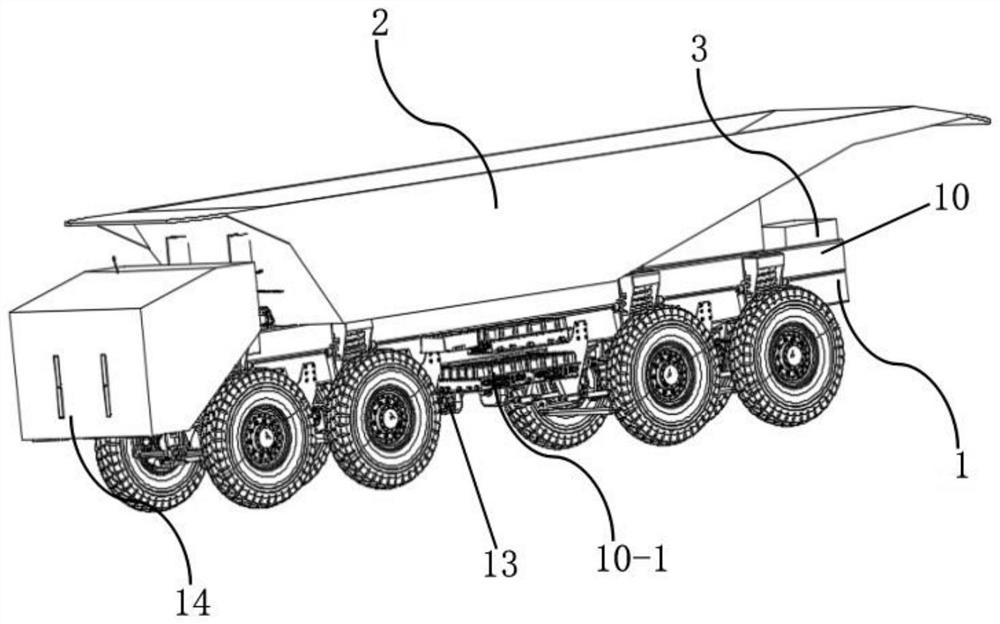

[0057] The hybrid two-way driving unmanned mining dump truck chassis of the present invention, through the calculation and control of the front and rear unmanned modules 3, when driving under high-load road conditions such as climbing and potholes, the range extender 14 works at full load Together with the power battery 10-1, the two drive motors 13-1 are supplied with energy, and the driving force is large at this time; when driving under low load conditions, according to the power status of the power battery 10-1, if the power is high, the range will be increased. The power battery 10-1 is used as the main power supply object. If the power is low, the range extender 14 is the main power supply object. If the power is lower than the warning line, the range extender 14 is the power battery 10 at the same time. -1 charging; when braking downhill, the drive motor 13-1 participates in braking, and feeds the braking energy back to the power battery 10-1; while saving energy and pro...

Embodiment 2

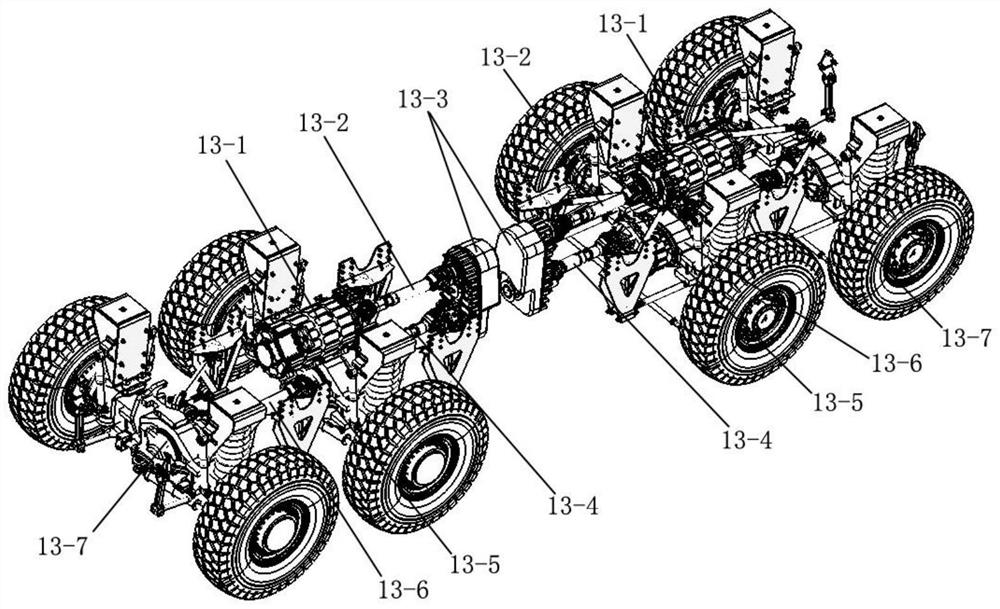

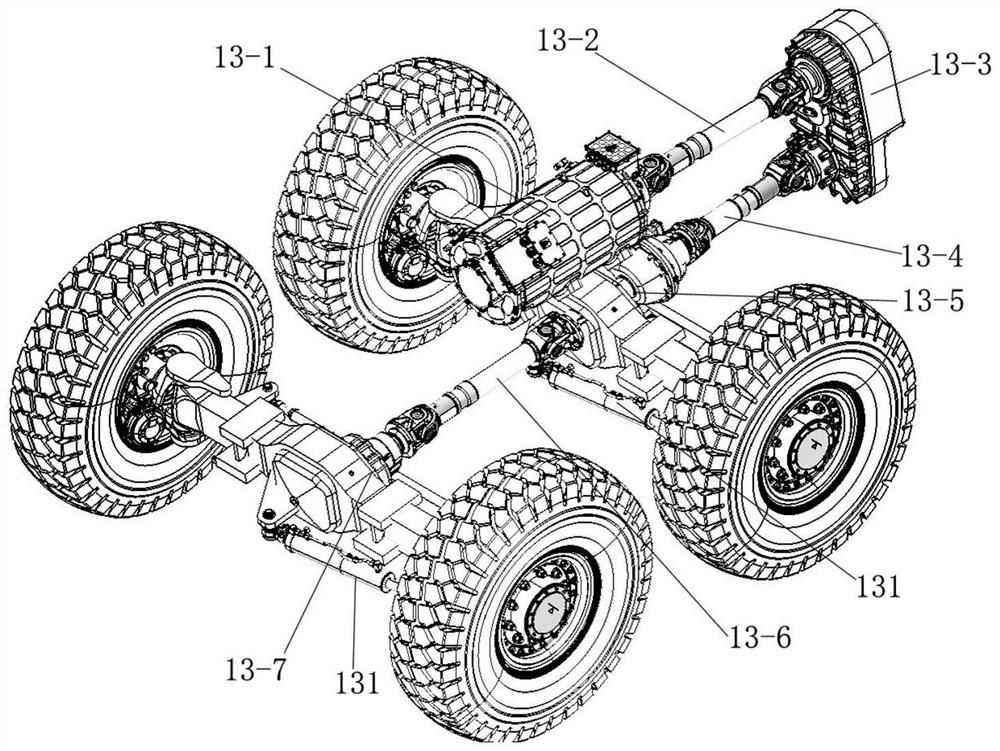

[0060] In the hybrid two-way driving unmanned mining dump truck chassis of the present invention, the forward and reverse gears of the gearbox 13-3 are the same, so that two-way driving is realized, and the original road can be returned without turning around, and the production efficiency is improved; The first steering drive axle 13-5 and the second steering drive axle 13-7 use a steering cylinder 131 for hydraulic steering. The engine 11 is provided with an oil pump 130, and the oil pump 130 takes power from the engine 11 to drive the steering cylinder 131 to move for steering. , realizes all-wheel steering, solves the problem of difficult turning of the vehicle in a narrow space, and at the same time improves the operation efficiency and vehicle driving safety.

Embodiment 3

[0062] The hybrid bidirectional driving unmanned mining dump truck chassis of the present invention adopts an unmanned system, which reduces human resources, improves the attendance efficiency of the mining dump truck, and saves human resources.

[0063] The front and rear unmanned modules 3 specifically include a fusion perception subsystem, a control subsystem, a remote subsystem, a vehicle interaction subsystem and an execution subsystem, and the control subsystem includes an automatic driving control system and a vehicle controller. The automatic driving control system and the vehicle controller are connected in data communication, the fusion perception subsystem and the automatic driving control system are connected through a data signal line, and the remote subsystem, the vehicle interaction subsystem and the execution subsystem are all connected to the vehicle controller. connect.

[0064] The automatic driving control system mainly completes the issuance of the automat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com