Multi-station machining equipment for anti-explosion self-locking leveraging wrench

A processing equipment, multi-station technology, applied in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., can solve the problems of poor mechanical assembly applicability, and achieve the effect of facilitating mechanical assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

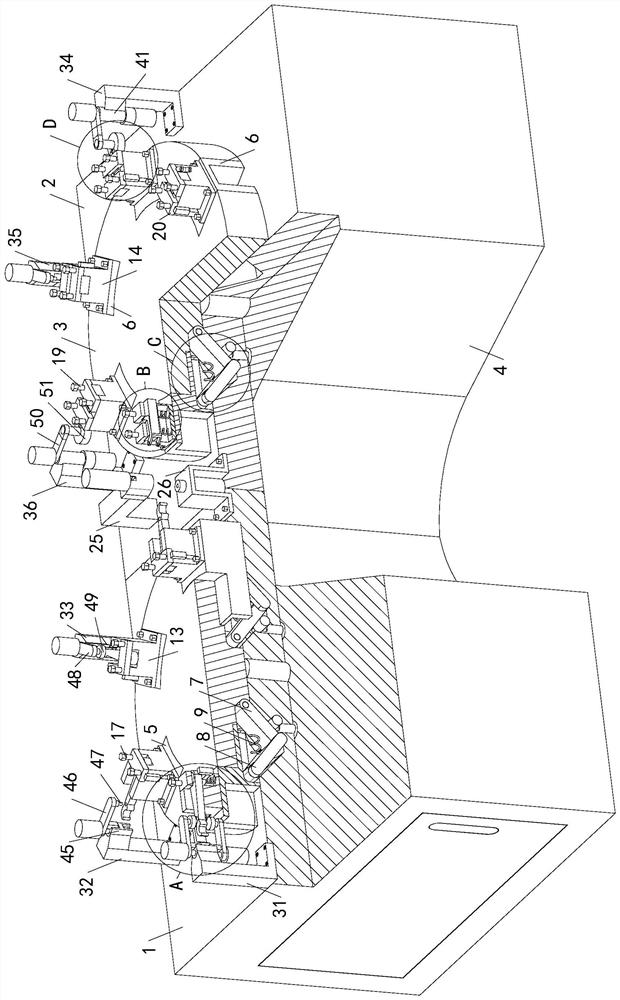

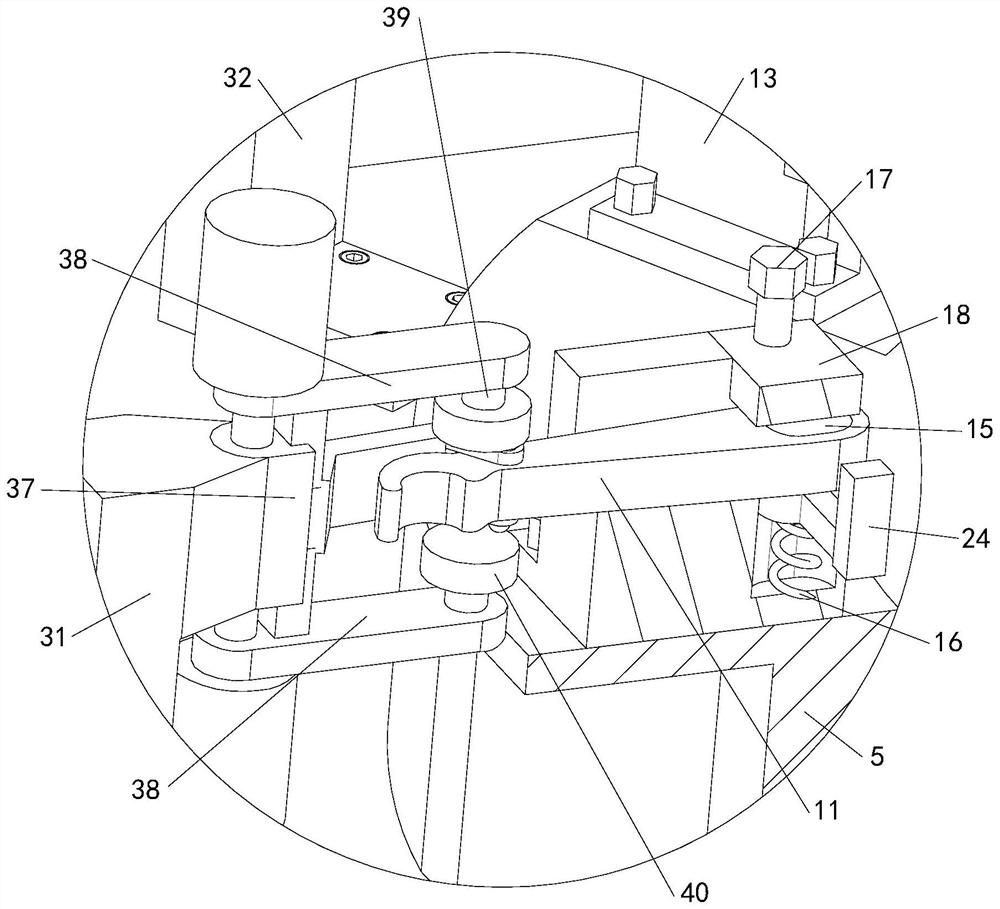

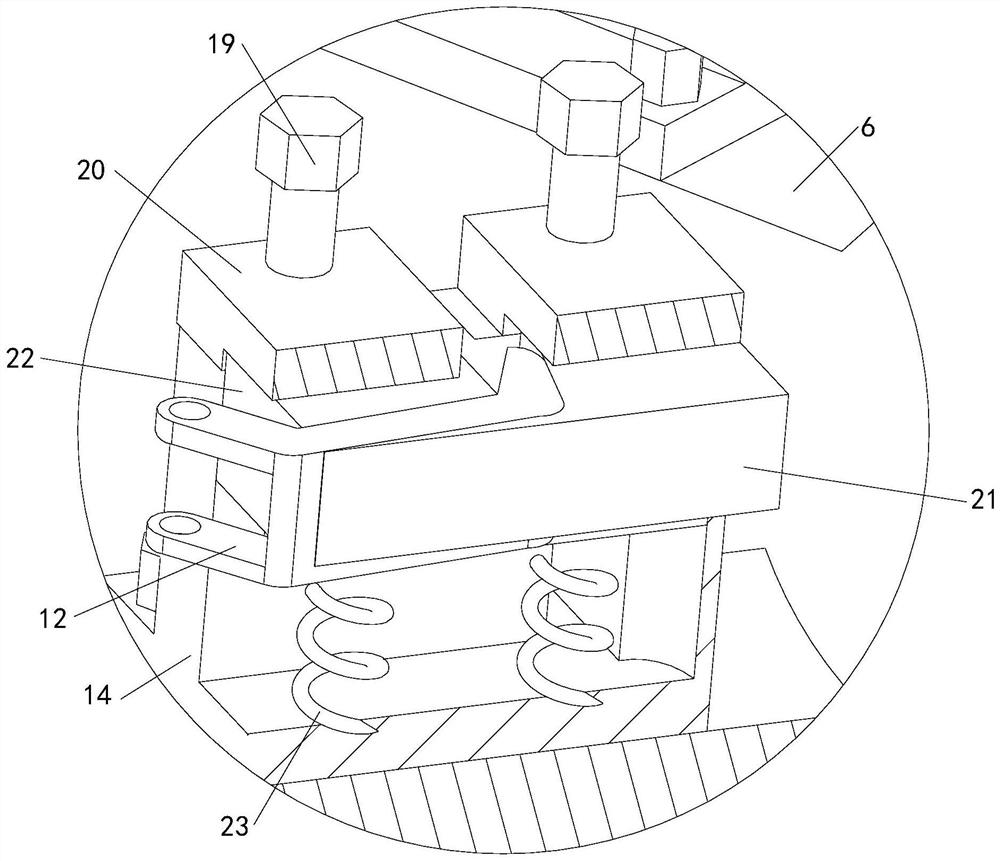

[0032] see Figure 1-7, a multi-station processing equipment for explosion-proof self-locking lever wrench, including a left bed 1 and a right bed 2, the left bed 1 and the right bed 2 are equipped with intermittent rotation around their axis The turntable 3 also includes a left processing system, a left positioning system, a right processing system and a right positioning system, and a wrench fixed part 11 and a wrench movable part 12 that cooperate with each other. The wrench fixed part 11 is provided with an auxiliary hole, and the wrench movable part 12 Upper preset is provided with installation gap, left positioning system and right positioning system respectively comprise a plurality of left pedestals 13 and a plurality of right pedestals 14, a plurality of left pedestals 13 are respectively installed on a plurality of left sliding frames 5, a plurality of right The base frame 14 is respectively installed on a plurality of right sliding frames 6, and the left base frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com