High-reliability liquid cooling system and control method

A control method and reliable technology, which is applied in the field of high reliability liquid cooling system and control, and can solve the problems of high outlet pressure of the main drive device, leakage prevention, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

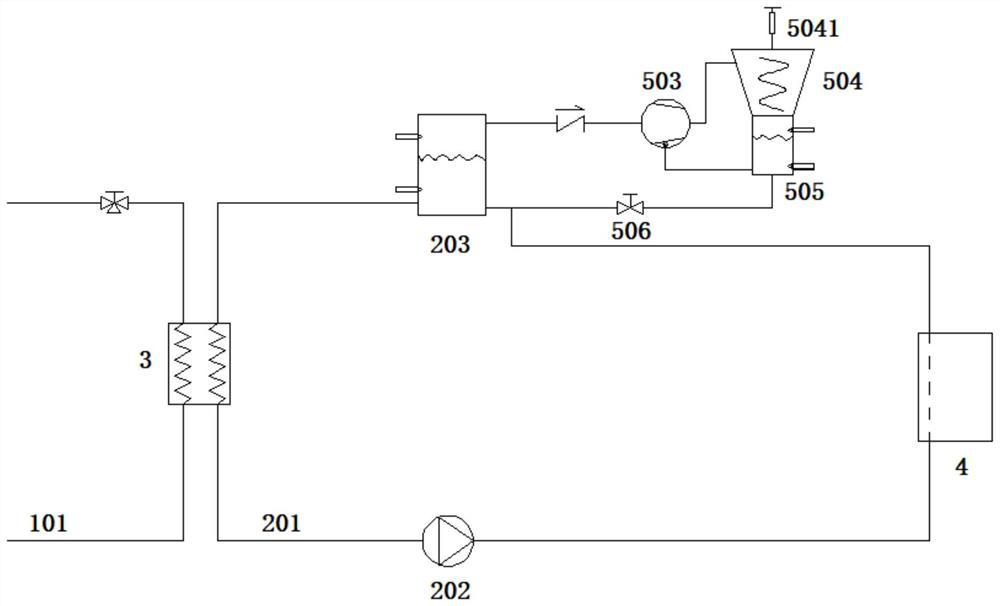

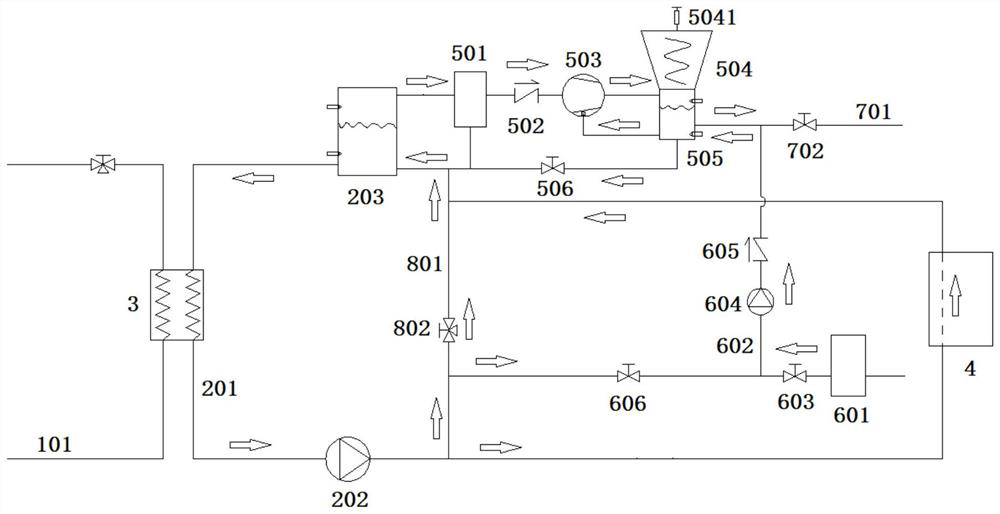

[0053] Such as figure 2 As shown, the high-reliability liquid cooling system of Embodiment 1 of the present invention is introduced, which includes a primary pipeline 101 for the flow of the primary refrigerant, a secondary pipeline 201 for the flow of the secondary refrigerant, and a circuit for driving the flow of the secondary refrigerant. The main driving device 202, the heat exchanger 3 used for heat exchange between the primary refrigerant and the secondary refrigerant, the pre-pump liquid storage tank 203 communicated with the secondary pipeline 201 and the pre-pump liquid storage tank 203 connected to the vacuum equipment 503 . Wherein, a pressure relief pipeline 801 is provided between the outlet of the main driving device 202 and the inlet of the liquid storage tank 203 before the pump, and a pressure relief valve 802 is provided on the pressure relief pipeline 801 .

[0054] It should be noted that, generally, the main driving device 202 drives the secondary refri...

Embodiment 2

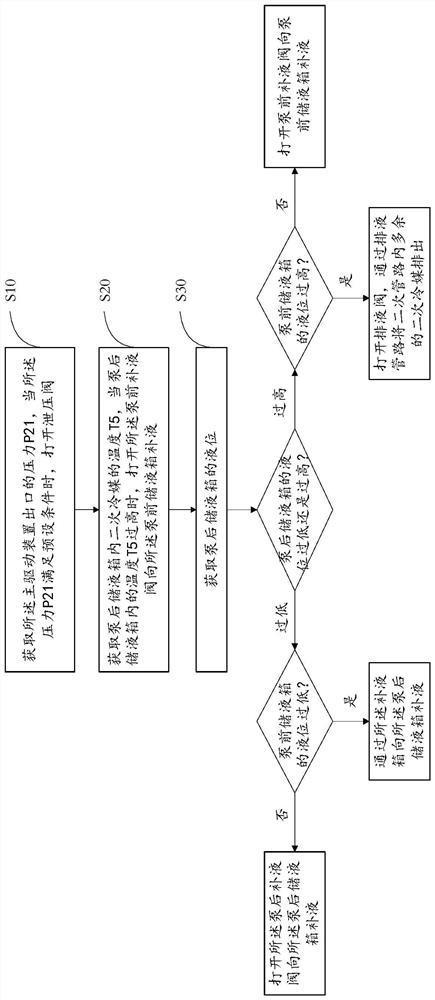

[0067] Such as image 3 As shown, the control method of Embodiment 2 of the present invention is introduced, which is suitable for figure 2 The highly reliable liquid cooling system provided by the illustrated embodiment 1 has the same function and technical effect.

[0068] Described control method comprises the steps:

[0069] S10: Obtain the pressure P21 at the outlet of the main driving device 202, and open the pressure relief valve 802 when the pressure P21 meets a preset condition;

[0070] After the pressure relief valve 802 is opened, the secondary refrigerant at the outlet of the main drive device 202 will flow directly to the liquid storage tank 203 in front of the pump through the pressure relief valve 802, thereby preventing the pressure in the secondary pipeline 201 from being greater than the atmospheric pressure, resulting in a negative pressure system. The anti-leakage function fails. Generally, it can be set that when the pressure P21>(1 bar-margin value),...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com