Height-adjustable textile machine tool

An adjustable, machine tool technology, used in textiles and papermaking, needle punching machines, non-woven fabrics, etc., can solve the problem of inconvenience for staff of different heights, and achieve easy operation for operators, wide range of use, and stable operation of the device. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following examples are for illustrative purposes only and are not intended to limit the scope of the invention.

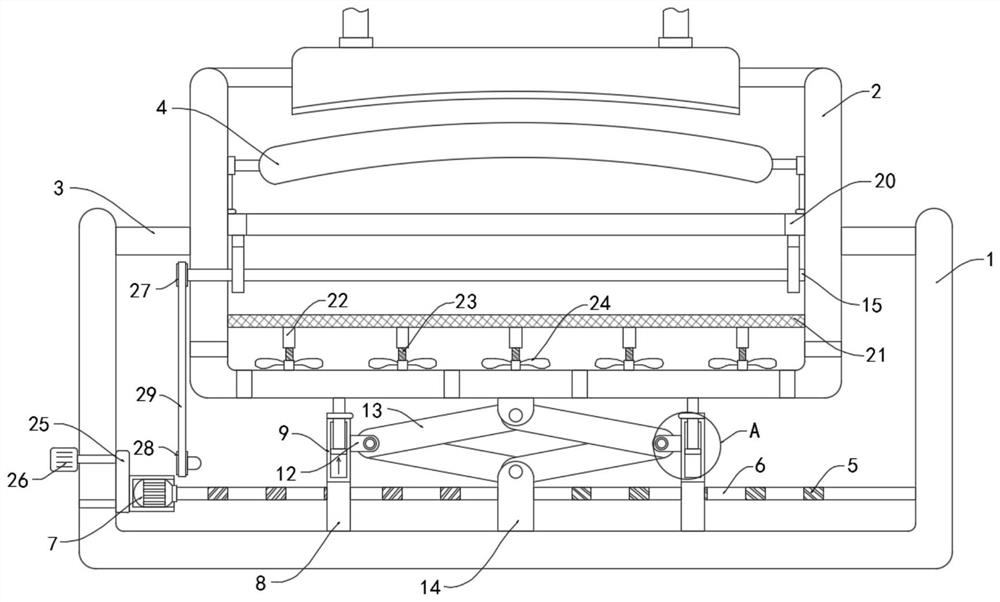

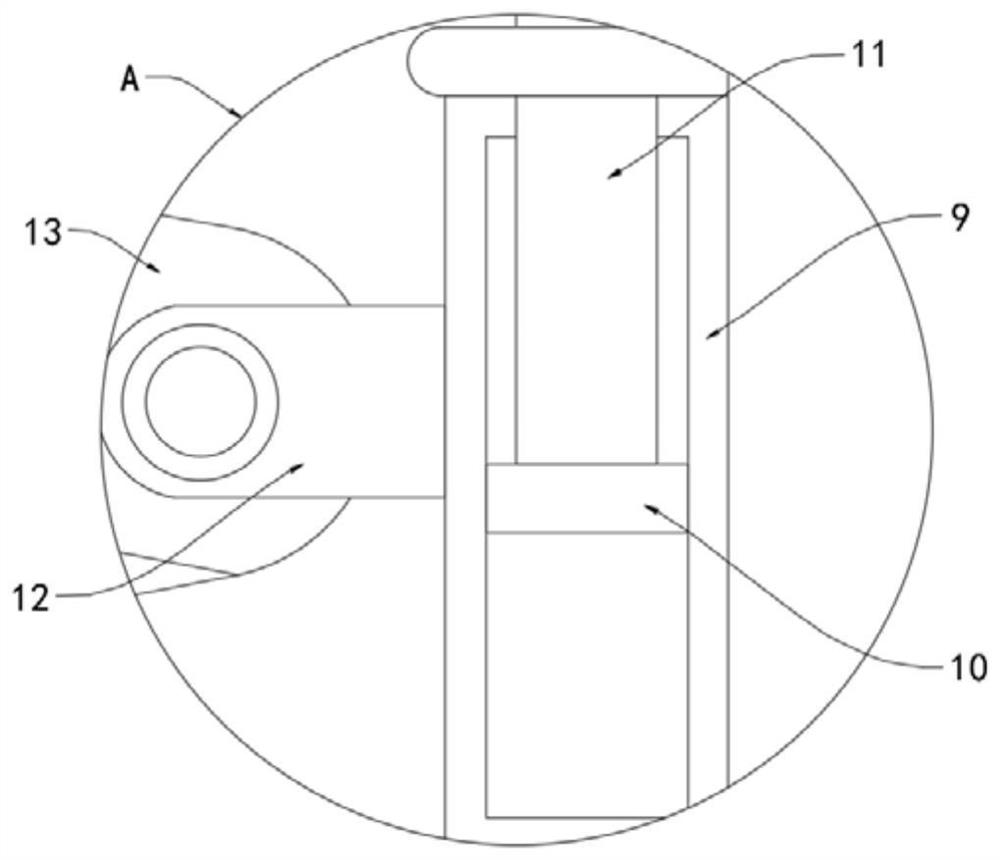

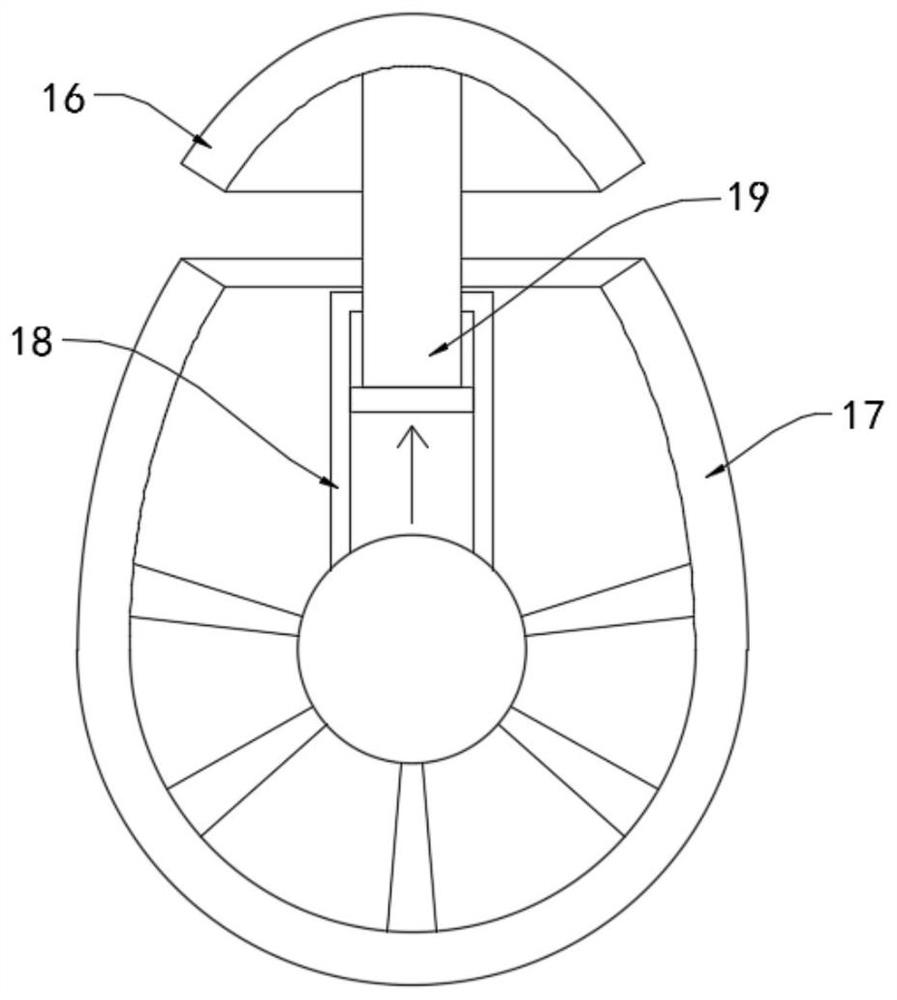

[0034] Such as Figure 1-4 As shown, a height-adjustable textile machine tool includes an outer machine frame 1 and a needle punching mechanism, an inner machine frame 2 is set inside the outer machine frame 1, and a horizontal ring is fixedly connected to the inner wall of the upper port of the outer machine frame 1. The plate 3 and the annular plate 3 are slidingly connected with the inner machine frame 2, and the outer machine frame 1 and the inner machine frame 2 can slide relatively;

[0035] The acupuncture mechanism is used to repeatedly puncture the non-woven fiber web, and the hook belt fiber is reinforced into a cloth. The acupuncture mechanism includes an acupuncture part fixedly arranged on the upper end of the inner machine frame 2, and the lower end of the acupuncture part is covered with evenly arranged needles. Components are prior art. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com