Forming mold for power turbine casing wax model

A power turbine and forming mold technology, which is applied to casting and forming equipment, can solve the problems of unfavorable injection hole position, difficult demoulding, and overall overweight of the forming mold, so as to achieve convenient demoulding method, convenient and stable demoulding process, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0031] Aiming at the existing problems of difficulty in demoulding, unfavorable positions of injection holes for dissolving injection materials, and overall overweight of the molding mold, the invention provides a molding mold for a power turbine casing wax mold.

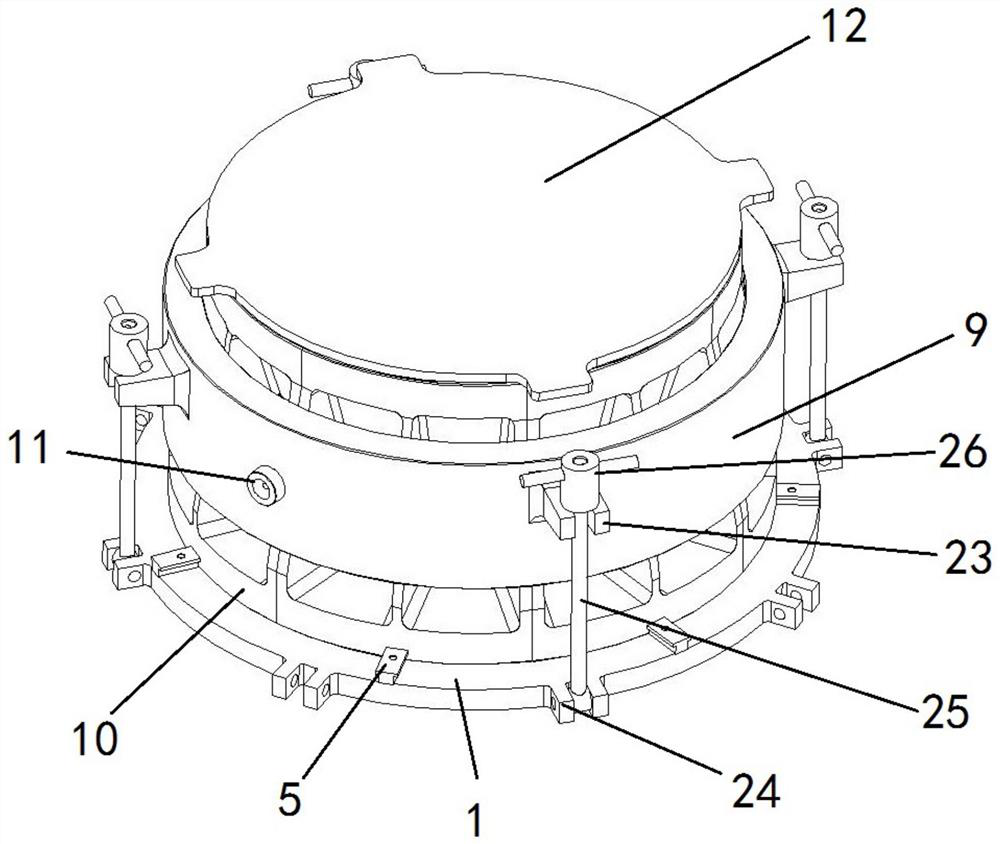

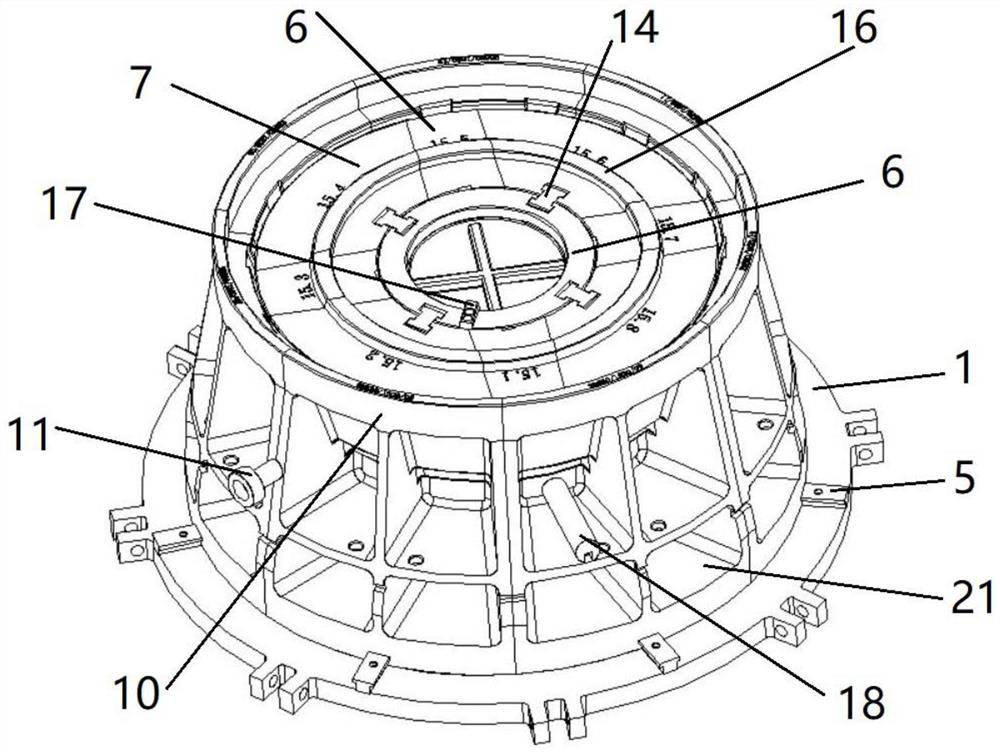

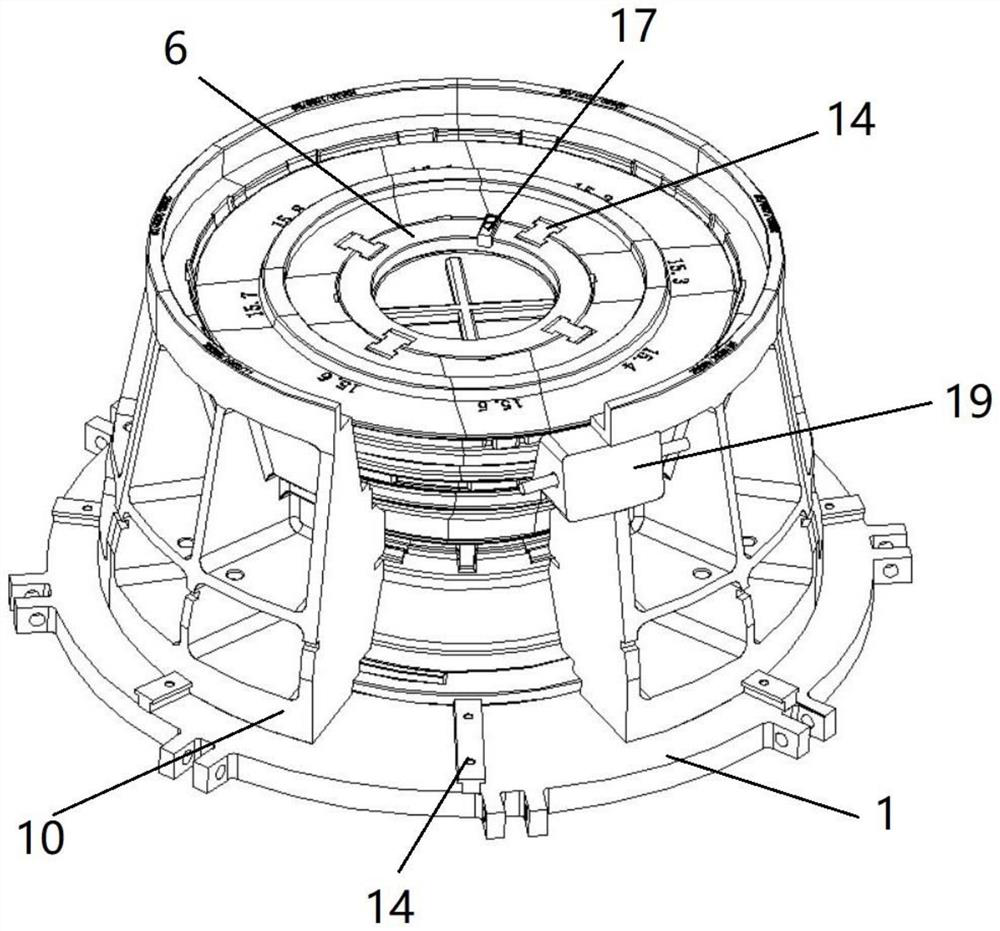

[0032] Such as Figure 1 to Figure 7 As shown, the embodiment of the present invention provides a molding die for a power turbine casing wax mold, including: a mold base 1, a bottom mold boss 2 is arranged at the center of the mold base 1, and the top surface of the bottom mold boss 2 is An inner mold groove 3 is provided, and the center of the inner mold groove 3 is provided with a through hole; the mold base 1 is provided with a ring template 4 around the bottom mold boss 2; the top surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com