Rigidity-variable soft mechanical arm

A soft-body machine and variable-stiffness technology, applied in manipulators, claw arms, manufacturing tools, etc., can solve the problems of reducing the load capacity of the manipulator and restricting the application of the software manipulator, and achieve the effect of good flexibility and good interactive security.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

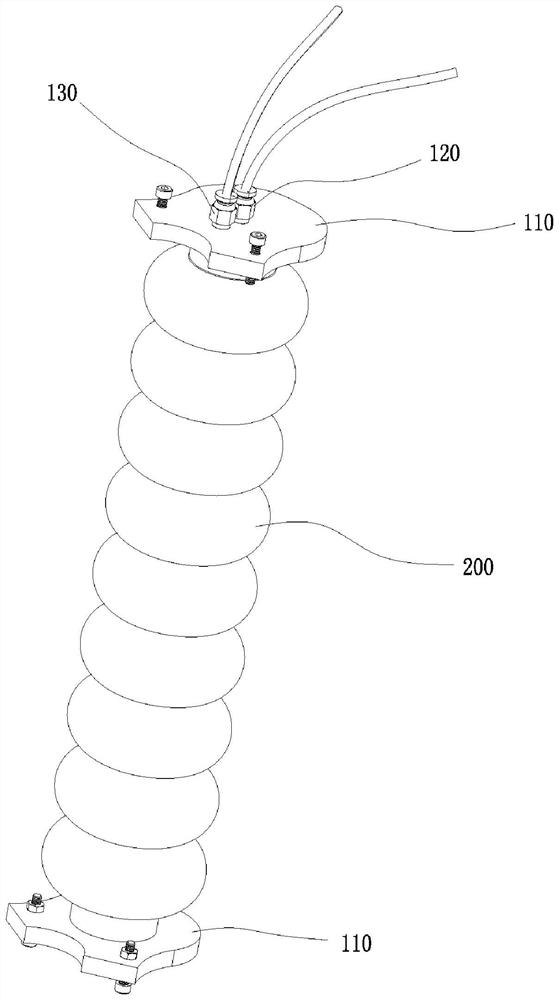

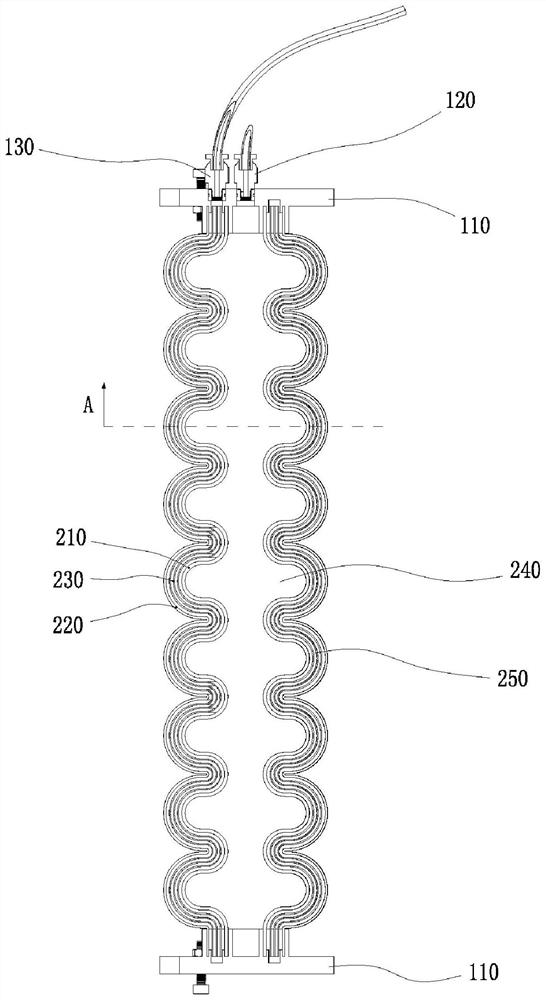

[0033] This embodiment provides a variable stiffness soft manipulator, such as Figure 1-6 As shown, it includes two connecting seats 100 and three bellows modules 200 arranged between the two connecting seats 100, wherein the three bellows modules 200 are arranged in parallel, and the three bellows modules 200 are spaced at intervals of 120 ° way parallel connection between the two connecting seats 100.

[0034] In this embodiment, one of the bellows modules 200 is taken as an example to illustrate its structure. The bellows module 200 includes an inner bellows 210, an outer bellows 220, and a variable stiffness body 230, wherein the inner bellows 210 forms a main ventilation cavity. The body 240 forms a variable stiffness cavity 250 between the inner corrugated tube 210 and the outer corrugated tube 220, and the variable stiffness body 230 is arranged in the variable stiffness cavity 250;

[0035] Further, the variable stiffness main body 230 has three hard particle layers ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com