Full-tab top cover assembly and full-tab battery

An all-pole ear and top cover technology, applied in battery pack parts, circuits, structural parts, etc., can solve problems such as poor battery performance and shaking, and achieve high assembly process accuracy, fast positioning, and excellent battery performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

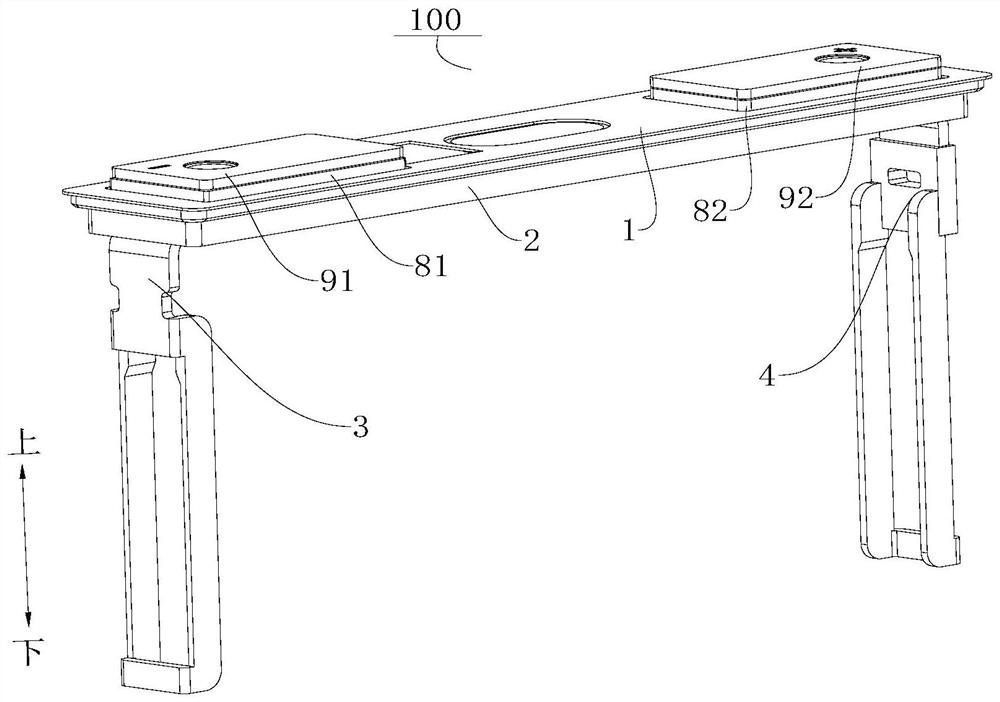

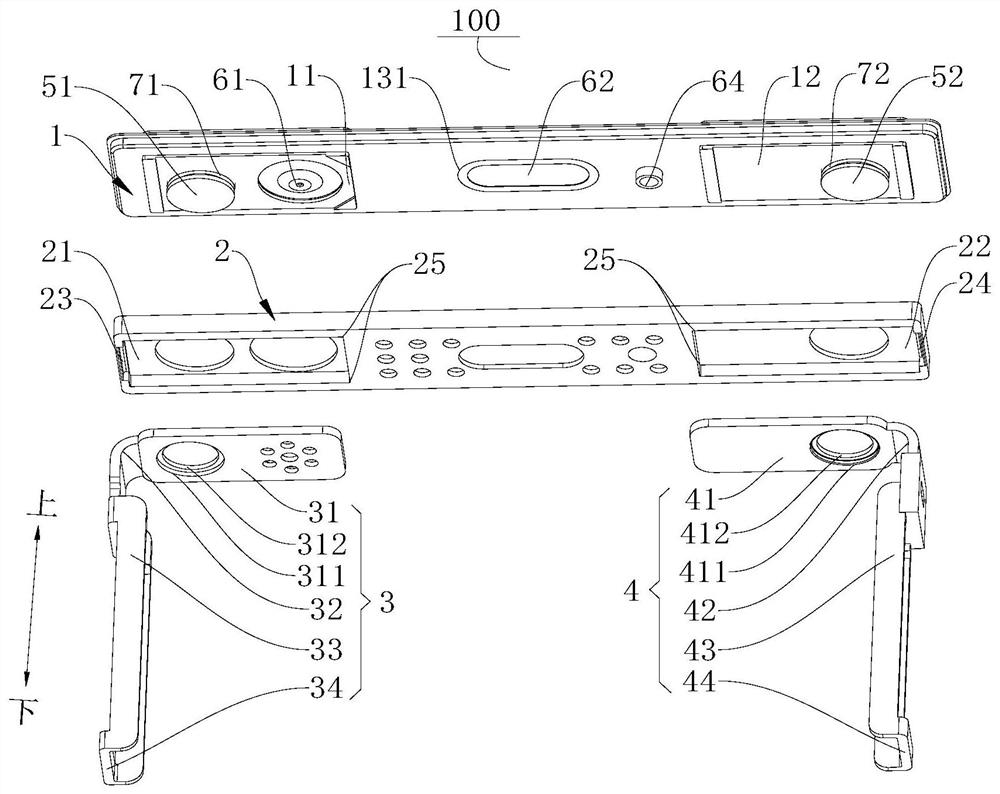

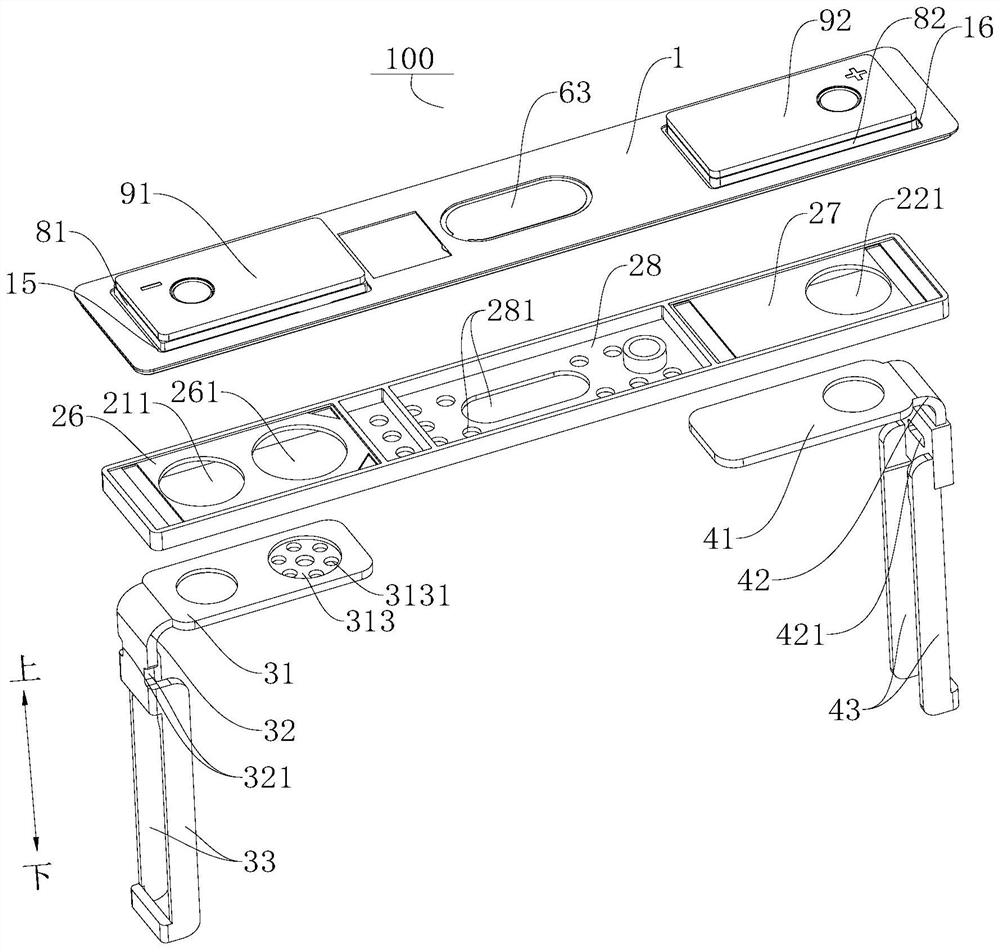

[0119] A full tab top cover assembly 100, such as figure 1 As shown, it includes: a top cover sheet 1 , a lower plastic sheet 2 , a first connecting sheet 3 and a second connecting sheet 4 .

[0120] Among them, such as figure 1 and figure 2 As shown, the lower plastic 2 fits on the bottom of the top cover sheet 1 .

[0121] like figure 2 As shown, the bottom of the lower plastic 2 is provided with a first groove 21 and a second groove 22 that are concave upward toward the direction of the top cover sheet 1, and the first groove 21 and the second groove 22 are respectively arranged on the lower plastic 2 at intervals. sides in the long direction. Continue to refer to figure 2 As shown, the first groove 21 has a first locking groove 23 on the groove wall of the side away from the second groove 22, and the first locking groove 23 communicates with the first groove 21; the second groove 22 is far away from the first groove. A second locking groove 24 is formed on one sid...

Embodiment 2

[0125] An all-tab battery 1000, comprising: two battery cells 200, a housing 300 and a full-tab top cover assembly 100, wherein the assembled all-tab battery 1000 can refer to Figure 6 shown.

[0126] like Figure 7 As shown, two battery cells 200 are housed in the casing 300 .

[0127] like Figure 7 and Figure 9 As shown, pole pieces of different polarities of the battery cell 200 protrude from both sides of the battery core 200, and some areas of the protruding pole piece are not coated with a coating, and the uncoated area protruding from the negative pole piece is formed as The first connecting portion 210 and the uncoated area protruding from the positive electrode tab are formed as the second connecting portion 220 .

[0128] like Figure 7 and Figure 8 As shown, the full-tab top cover assembly 100 is the full-tab top cover assembly 100 in Embodiment 1, as Figure 6 As shown, the full tab top cover assembly 100 is covered on the shell 300, as Figure 8 As sho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com