A large-diameter packer capable of hanging screens

A large-diameter, screen-pipe technology, which is applied in sealing/isolation, wellbore/well components, construction, etc., can solve the problems of cumbersome operation steps, increased operation cycle, strong impact force, etc., and achieves good suspension effect, setting Stable and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

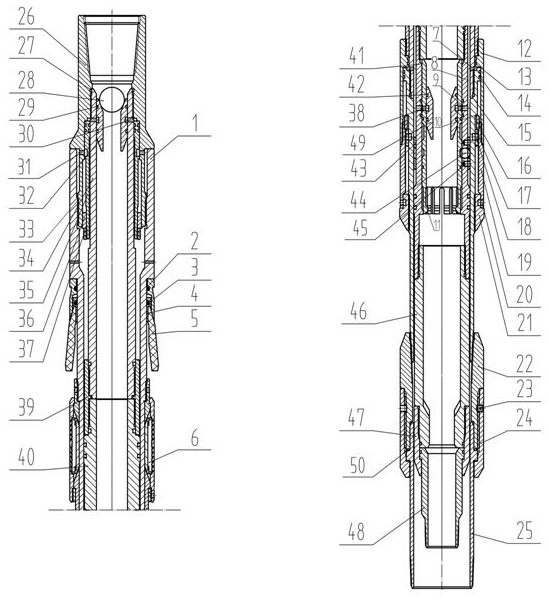

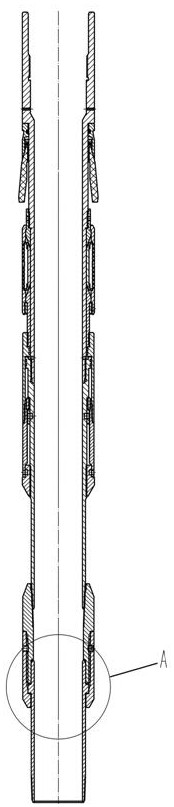

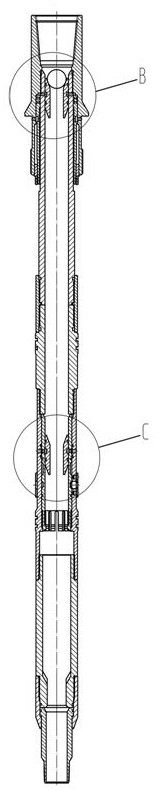

[0057] see Figure 1 to Figure 8 , a large-diameter packer capable of hanging a screen tube, comprising a well-retaining part and a service part detachably installed in the well-retaining part.

[0058] The well-retaining part includes a self-sealing structure, a seat-sealing mechanism 6 and a hydraulic pushing mechanism.

[0059] The service part includes the lifting and disengaging mechanism, the starting protection mechanism, and the circulation protection mechanism.

[0060] The self-sealing structure includes an upper center pipe 1 , and a bowl rubber cylinder 5 is installed on the outer middle part of the upper center pipe 1 . Specifically, a guard ring 2 is threadedly connected to the upper outer middle part of the upper center pipe 1 , and a vulcanization ring 4 is threadedly connected to the bottom of the guard ring 2 . , the bottom of the vulcanization ring 4 is vulcanized and connected with the top of the bowl rubber cylinder 5.

[0061] The rubber bowl 5 and the ...

Embodiment 2

[0089] This embodiment is optimized on the basis of Embodiment 1, specifically:

[0090] The bottom of the lower joint 15 is also connected with a quick-connecting mechanism, and the quick-connecting mechanism includes a quick-connecting head 22 , a quick-connecting sheath 24 and an adaptable joint 25 .

[0091] The quick connection head 22 is threadedly connected to the bottom of the lower joint 15, the quick connection sheath 24 is threadedly connected to the outside of the lower end of the quick connection head 22, an anti-rotation pin 23 is arranged between the quick connection head 22 and the quick connection sleeve 24, and the adaptable head 25 The top of the swivel is rotatably installed inside the quick connect head 22 and the quick connect sheath 24 .

[0092] An axial rotating groove is formed between the quick connecting head 22 and the quick connecting sheath 24 , and a rotating boss 251 which is matched with the rotating groove is provided on the outer peripheral ...

Embodiment 3

[0097] In this embodiment, on the basis of Embodiment 1, the sealing between various components is optimized, specifically:

[0098] A set of first sealing rings 3 are arranged between the vulcanization ring 4 and the upper central tube 1 , a second sealing ring 13 is arranged between the pushing sleeve 12 and the upper central tube 1 , and a set of first sealing rings 13 are arranged between the pushing sleeve 12 and the lower joint 15 . Three sealing rings 14 .

[0099] A fourth sealing ring 27 is provided between the hydraulic rod 34 and the upper joint 26 , and a fifth sealing ring 29 is provided between the hydraulic rod 34 and the upper ball seat 32 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com