Agricultural organic waste fermentation system and method

A technology for organic waste and fermentation systems, applied in biochemical equipment and methods, biological material sampling methods, bioreactor/fermentation tank combinations, etc., can solve the problems of increased material viscosity, poor thermal conductivity, and difficult discharge, etc. problem, to achieve the effect of increasing the stirring torque, improving the stirring effect and improving the heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

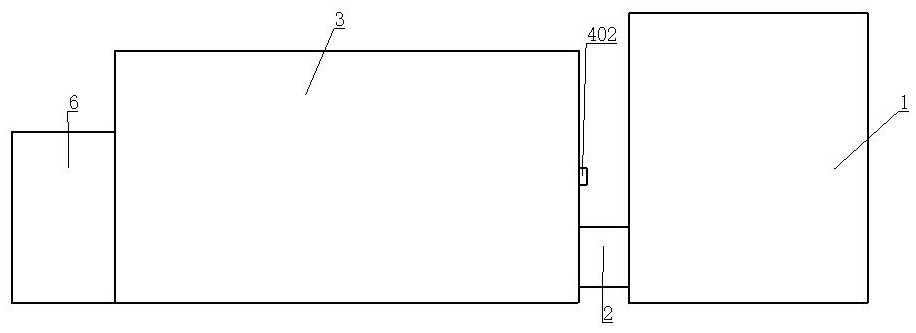

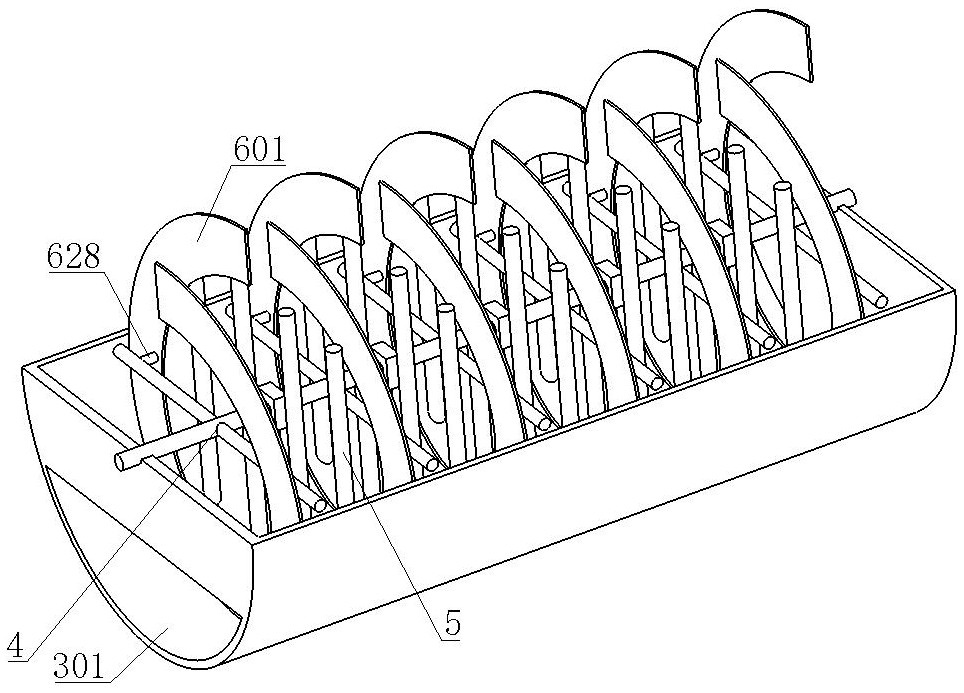

[0049] An agricultural organic waste fermentation system, such as Figure 1-16 Shown, comprising a pretreatment device, the pretreatment device is connected to a fermentation device, the pretreatment device comprises a crushing device 1 and an infeed device 2 connected to the inlet, the fermentation device comprises a fermentation tank 3, the fermentation tank 3 is provided with a uniform heating device, and there is also a stirring device 4 in conjunction with the uniform heating device.

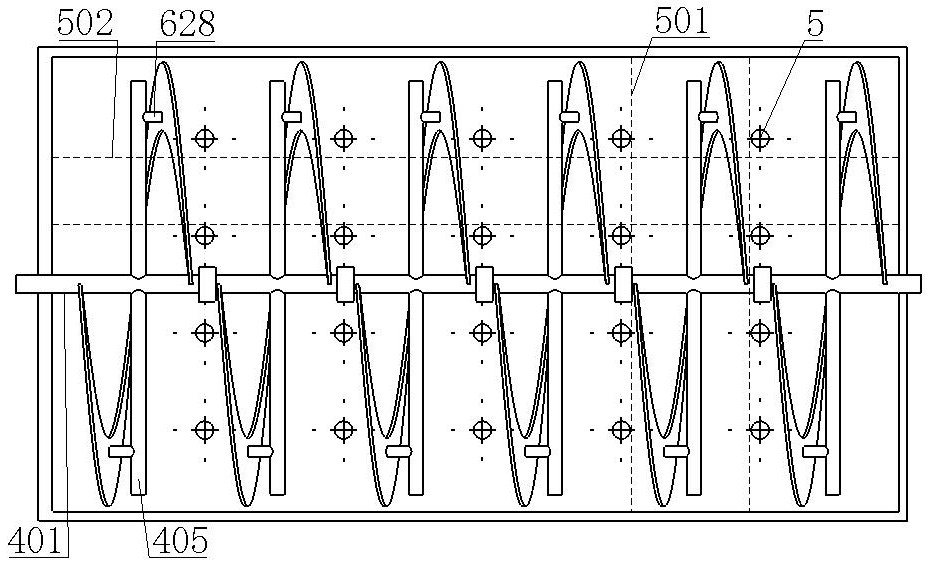

[0050] as Figure 1-6As shown, the fermentation tank 3 is a hollow cylindrical structure set horizontally, the front and rear ends of the fermentation tank 3 are opened with an inlet and an outlet port 301, the inlet is connected to the feed device 2, and the feed device 2 is connected to the crushing device 1 at one end away from the feed port; the heating device includes a heating tube 5 set vertically inside the fermentation tank 3, each heating tube 5 is a vertical cylindrical structure, and...

Embodiment 2

[0059] Embodiment 1 of the method of agricultural organic waste fermentation system, comprising the following steps:

[0060]Step 1, add materials; the waste straw and other materials are added to the crushing device 1, the crushing device 1 is crushed, the feed device 2 transports the material from the inlet to the fermentation tank 3; when the material is added to the fermentation tank 3, each first motor 410 rotates and drives the drive shaft 409 to rotate, the transmission shaft 409 drives the second bevel gear 407 at the top of it to rotate, the second bevel gear 407 drives the first bevel gear 406 to rotate and its meshing connection, and the first bevel gear 406 drives the second stirring shaft 403 to rotate, The second stirring shaft 403 drives the stirring rod 405 and the rotating blade 601 rotates, the rotating blade 601 pushes the material from front to back, the material is transported to the fermentation tank 3, the material enters the fermentation tank 3, and the in...

Embodiment 3

[0064] The present embodiment is the same as other portions of Example 2, the difference is, e.g., Figure 17-19As shown, the top of the fermentation tank 3 is sealed with a closed shell 302, the closed shell 302 is internally connected with the fermentation tank 3, the closed shell 302 is provided with a cleaning device corresponding to the heating tube 5 7, the cleaning device 7 includes a scraping ring 701 directly above each heating tube 5, the scraping ring 701 is a circular structure coaxial to the addition of the tube, the inner diameter of the scraping ring 701 is 2-5mm larger than the outer diameter of the heating tube 5, the outer ring surface of the lower half of the scraping ring 701 is inclined, and the slope is inclined from top to bottom to its axis. Scraping ring 701 on the vertical surface of the projection of the upper half is rectangular, the lower half is a large and small trapezoidal. Scraping ring 701 is connected to the upper part of the lifting mechanism 70...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com