Novel continuous melting material melting equipment

A melting and new type of technology, applied in the direction of feeding device, chemical industry, climate sustainability, etc., can solve the problems of wasting steam, dirty discharge and reducing the service life of equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

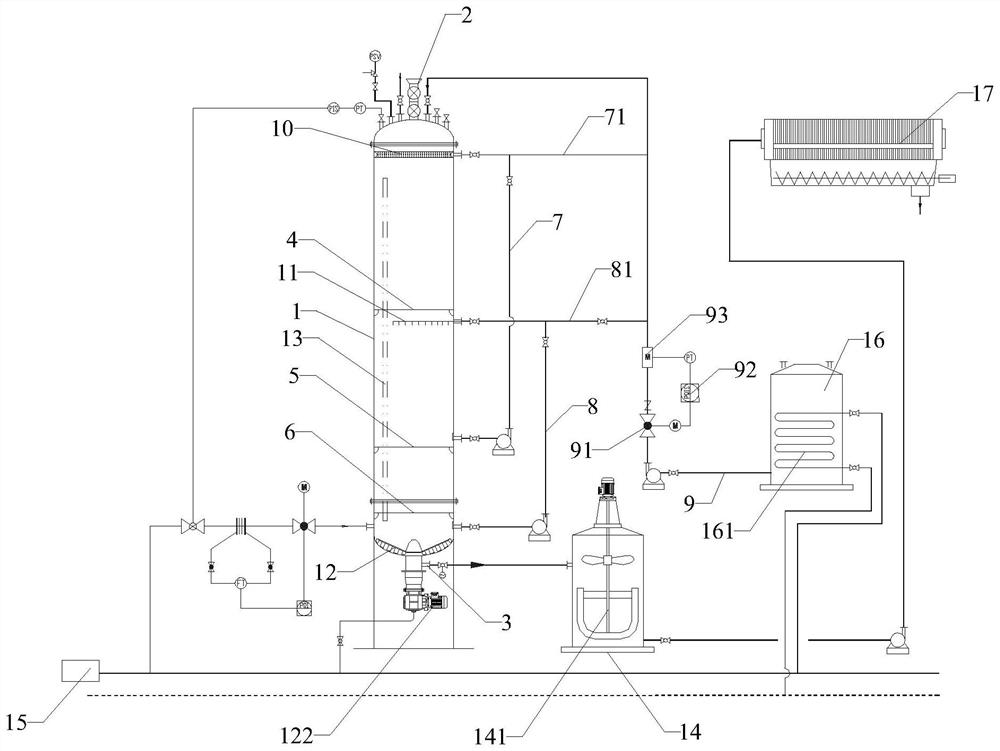

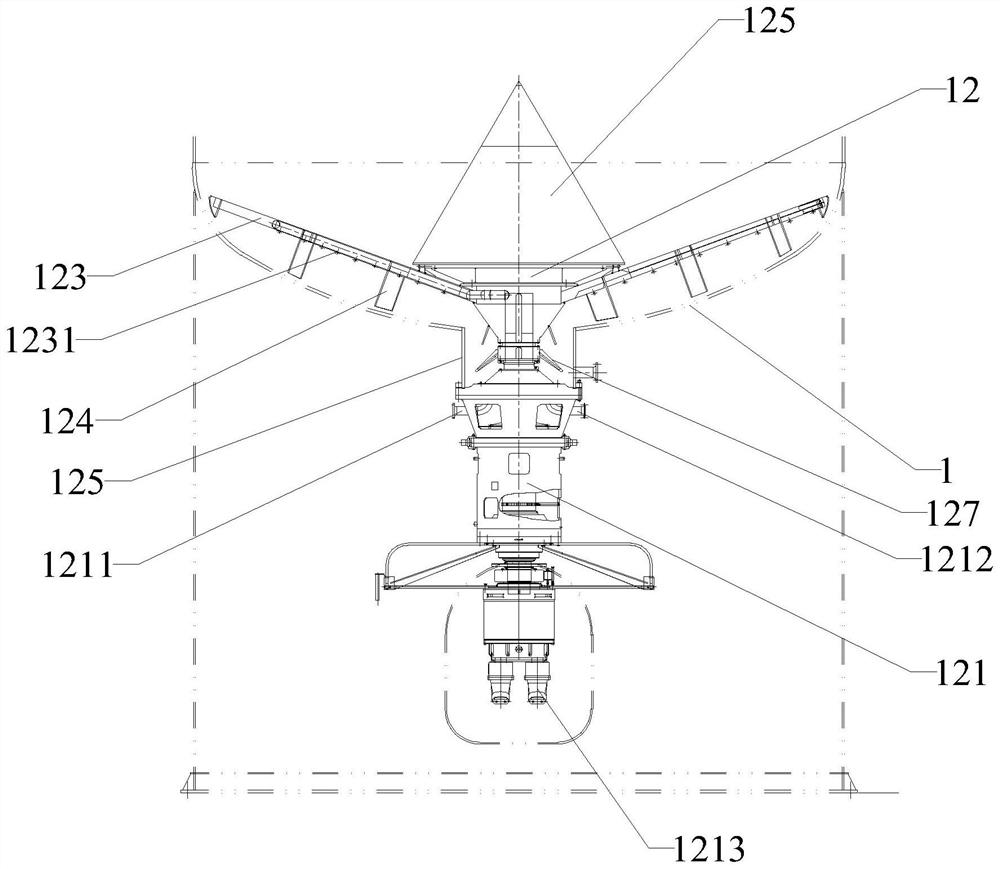

[0052] Please refer to Figure 1 to Figure 3 , a new type of continuous melting material equipment, including:

[0053] Chemical material tank body 1, the chemical material tank body 1 is cylindrical with the axial direction being vertical;

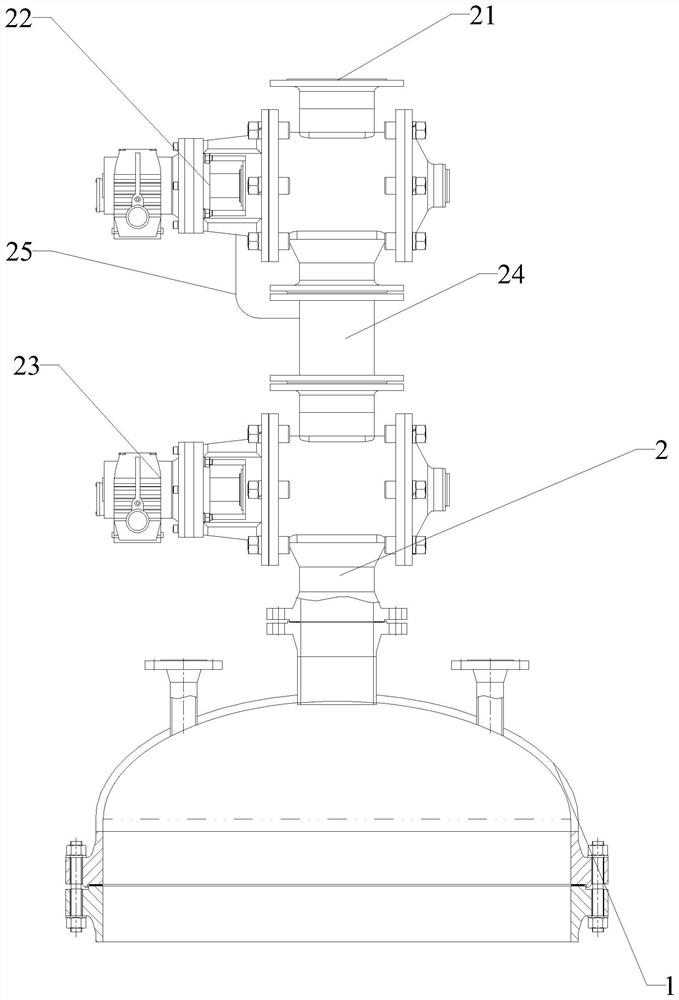

[0054] Feeding device 2, the feeding device 2 is connected to the top of the chemical tank body 1;

[0055] A discharge port 3, the discharge port 3 is arranged at the bottom of the chemical tank body 1;

[0056] The first sieve plate 4, the first sieve plate 4 is arranged inside the chemical tank body 1;

[0057] The second sieve plate 5, the second sieve plate 5 is arranged inside the chemical material kettle body 1, the second sieve plate 5 is located below the first sieve plate 4, and the sieve hole of the second sieve plate 5 is smaller than the first sieve plate 5 A sieve hole of the sieve plate 4;

[0058] The third sieve plate 6, the third sieve plate 6 is arranged inside the chemical material kettle body 1, the third sieve pl...

Embodiment 2

[0082] The novel continuous melting material equipment described in embodiment 1, wherein, also includes:

[0083] A slurry buffer tank 14 , the liquid inlet end of the slurry buffer tank 14 communicates with the discharge port 3 of the chemical tank body 1 ;

Embodiment 3

[0085] In the novel continuous melting material equipment described in Example 1, the discharge port 3 is provided with an electric control valve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com