Detection device applied to automatic detection of performance of pipeline gas self-closing valve

A technology of gas self-closing valve and detection device, which is applied in the direction of measuring device, liquid tightness measurement using liquid/vacuum degree, mechanical valve test, etc., which can solve the troublesome operation, detect self-closing valve alone, and affect the detection of self-closing valve Efficiency and other issues, to achieve the effect of precise and controllable lifting stroke, compact equipment structure and saving installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

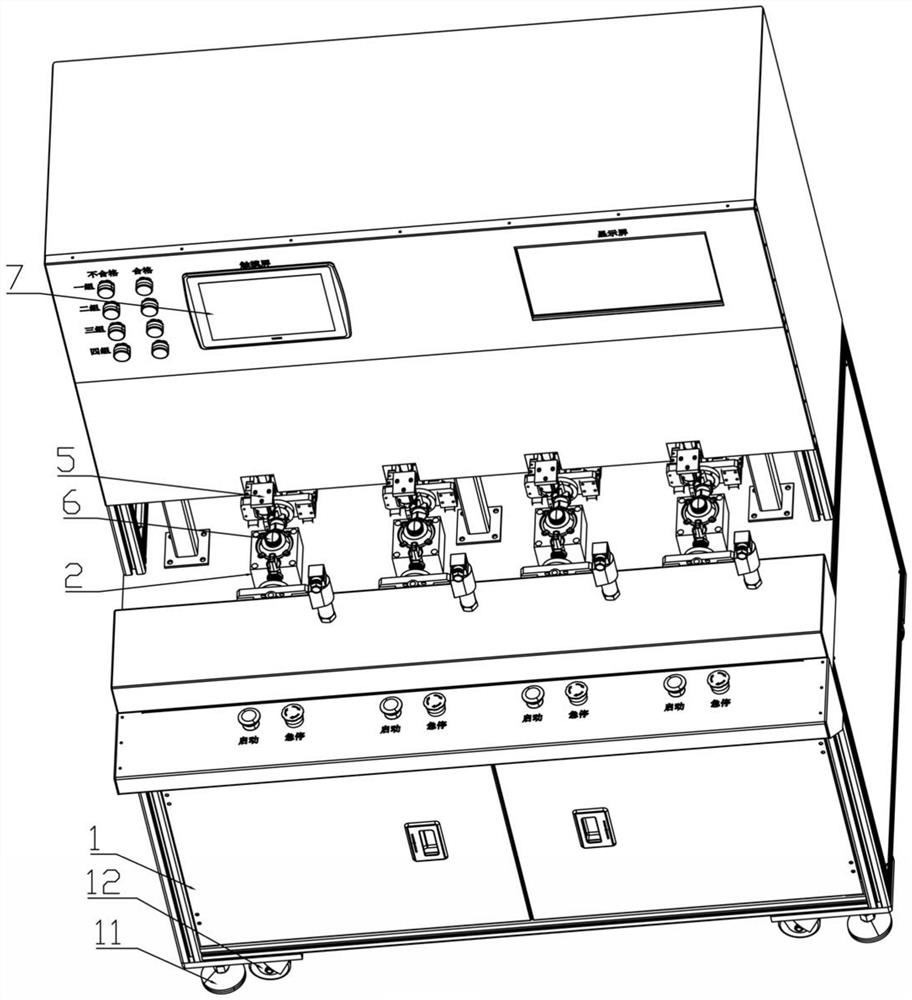

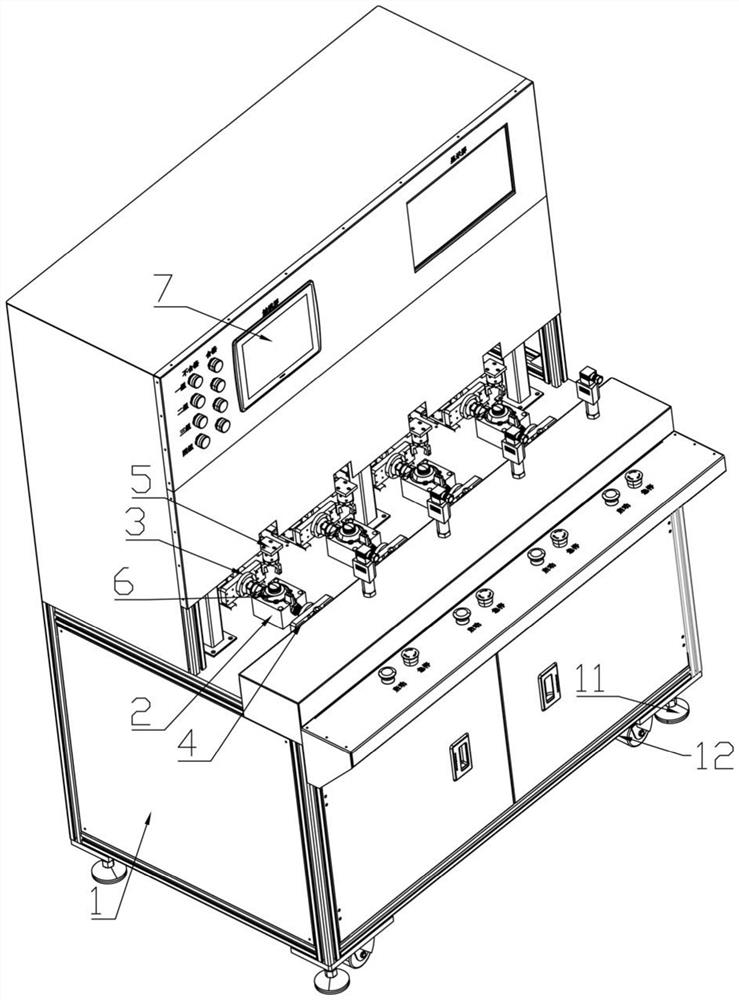

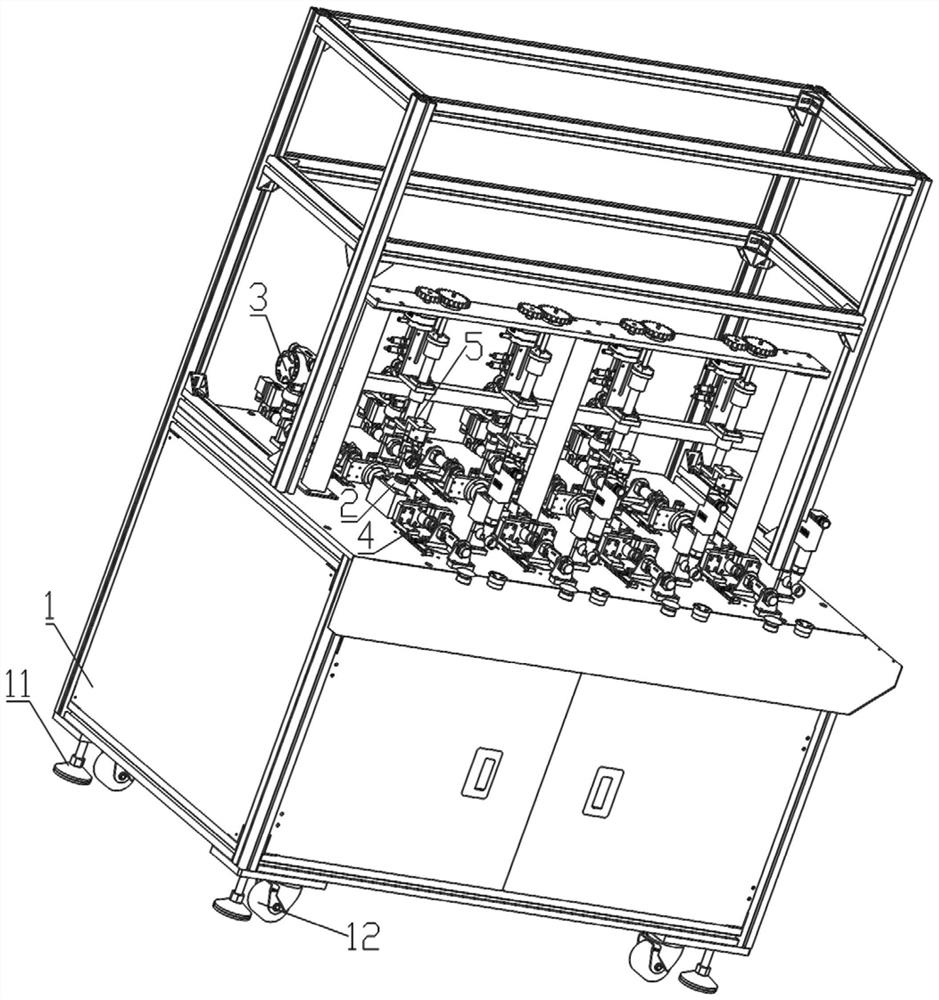

[0034] like Figure 1-10 As shown, Embodiment 1 of the present invention provides a detection device applied to the automatic detection of the performance of the pipeline gas self-closing valve 6. The detection device includes a workbench 1 and four sets of tooling positions 2 installed on the workbench 1. Inlet detection device 3, air outlet detection device 4, PLC controller 7 is installed in front of the workbench 1, suction cup support feet 11 are installed at the bottom four corners of the workbench 1, moving wheels 12 are installed at the bottom of the workbench 1, The moving wheel 12 is installed on one side of the suction cup support foot 11, and each set of tooling positions 2 is provided with an accommodation cavity 21 for supporting and fixing the self-closing valve 6, and the four sets of tooling positions 2 are installed on the air inlet detection device 3 and the air outlet Between the detection devices 4, the air inlet detection device 3 is connected to the air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com