Valve with fuel tank liquid accumulator and fuel tank liquid accumulator

An effusion device and fuel tank technology, which is applied in the directions of valves, valve devices, and functional valve types for ventilation, can solve the problems of difficulty in layout and increase in the cost of external effusion devices, and achieves solutions to difficult layout and cost. Increased, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

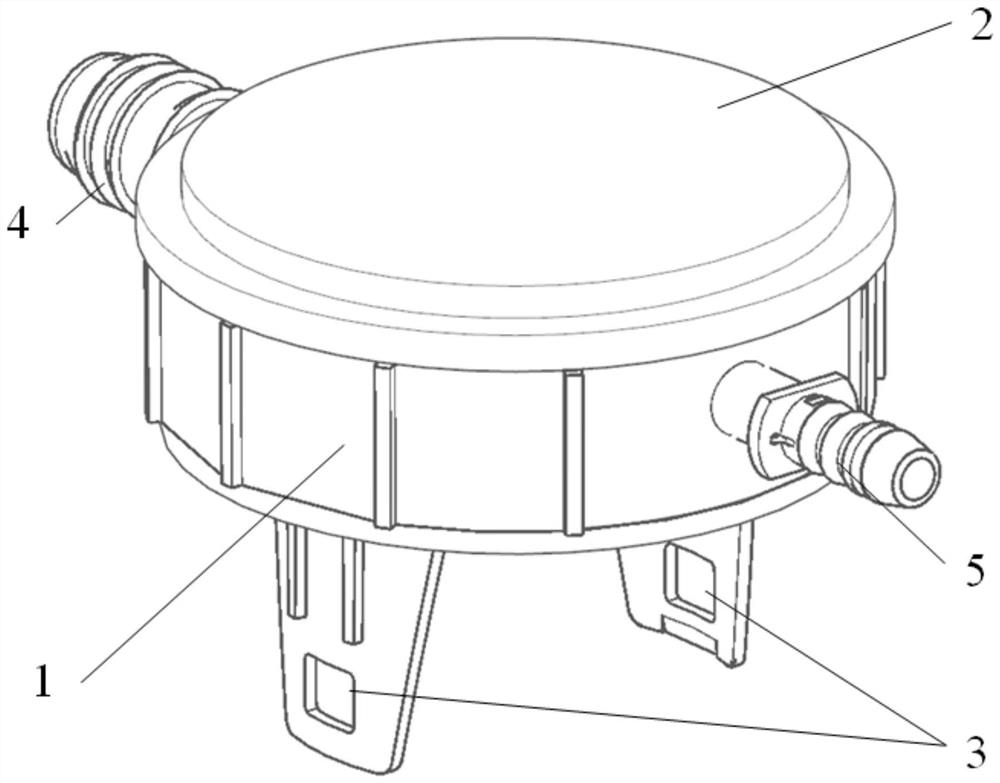

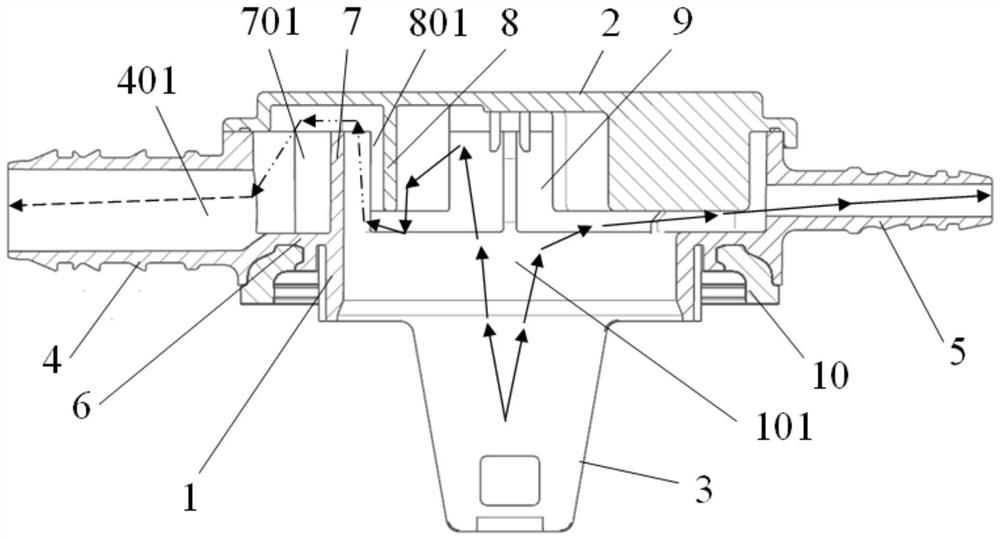

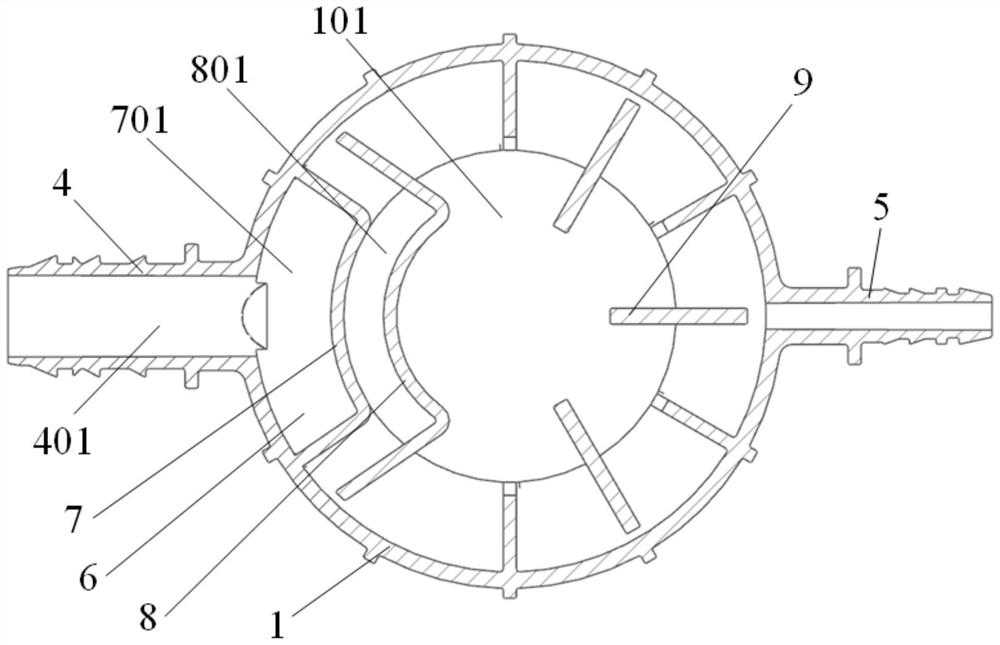

[0051] see Figure 1 to Figure 3 as well as Figure 5 , In one embodiment, a valve with a fuel tank accumulator includes: a valve body, a liquid accumulation cavity 101 body and at least one blocking unit.

[0052] The valve body is arranged on the fuel tank, and is used for discharging the gas in the fuel tank. A liquid accumulation cavity 101 and a gas channel 401 are arranged in the body of the liquid accumulator, and the output end of the gas channel 401 communicates with an external pipeline. The barrier unit is arranged in the liquid accumulation cavity 101, and is used to form a liquid barrier channel through which gas can flow in the liquid accumulation cavity 101. The two ends of the liquid barrier channel communicate with the liquid accumulation cavity 101 and the input end of the gas channel 401 .

[0053] Wherein, the liquid accumulator body is covered and sealed to the valve body, and the liquid accumulator chamber 101 communicates with the exhaust channel of t...

Embodiment 2

[0082] This embodiment provides a fuel tank accumulator, comprising: an accumulator body and at least one blocking unit.

[0083] A liquid accumulation cavity 101 and a gas channel 401 are arranged in the body of the liquid accumulator, and the output end of the gas channel 401 communicates with an external pipeline. The blocking unit is arranged in the liquid accumulation chamber 101 to form a liquid blocking channel through which gas can flow in the liquid accumulation chamber 101 .

[0084] Wherein, the liquid accumulator body is used for covering and sealingly connected to the external valve body 11 , and the liquid accumulating chamber 101 communicates with the exhaust channel of the external valve body 11 .

[0085] The existing connecting flange is replaced by setting the liquid accumulation body on the external valve body 11; the liquid accumulation chamber 101 and the gas channel 401 communicated with the external pipeline are arranged in the liquid accumulation body,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com