Novel speed reducer device

A reducer, a new type of technology, applied in the direction of transmission parts, mechanical equipment, gear lubrication/cooling, etc., can solve the problems of excessive consumption of lubricating oil, poor lubrication effect, large friction, etc., to solve the problem of excessive consumption of lubricating oil , Easy to install and disassemble the effect of the rotating shaft

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

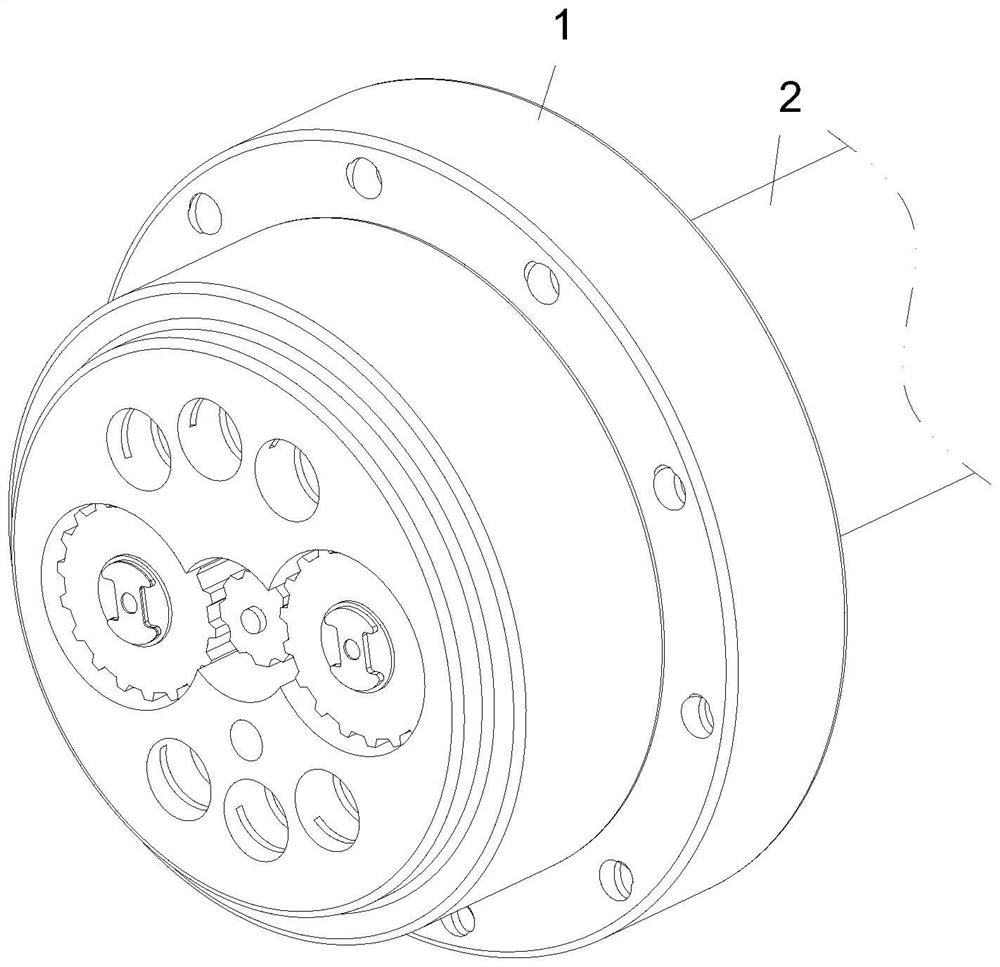

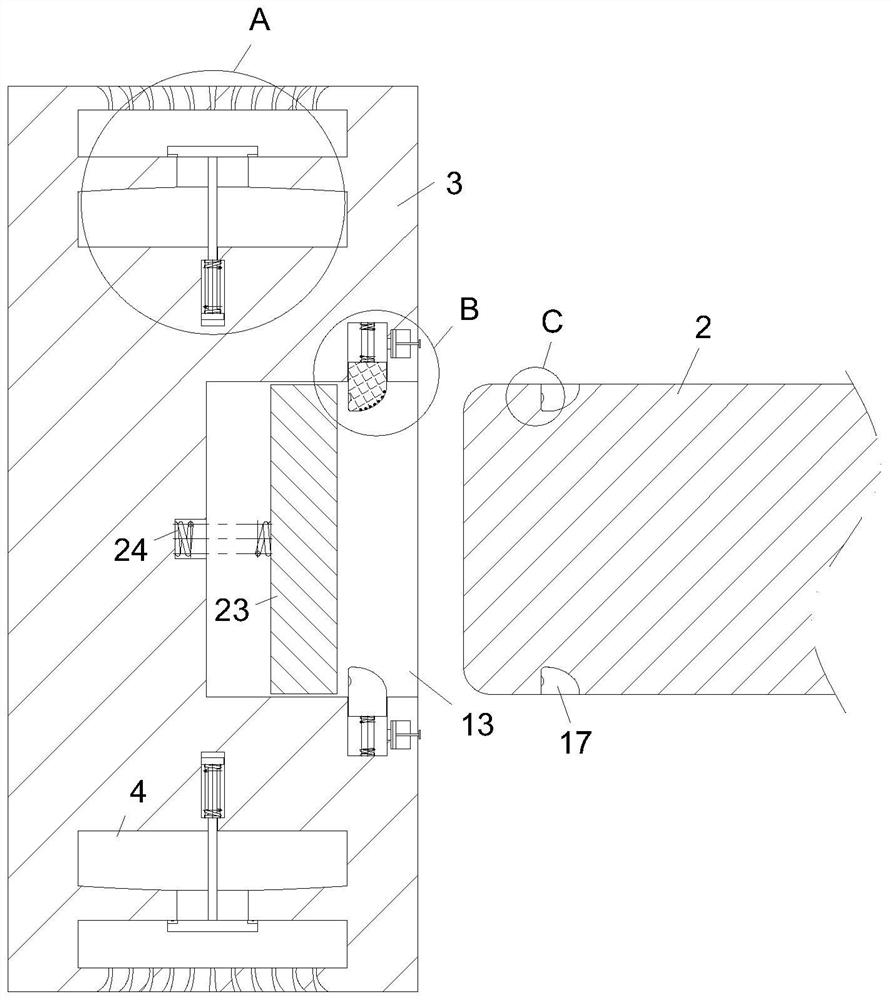

[0027] see Figure 1-6 As shown, a new type of reducer device includes a reducer body 1; a drive gear 3 is installed inside the reducer body 1; a plunger groove 13 is provided on the side of the drive gear 3; The inside of the reducer body 1 is equipped with a rotating shaft 2 through a fixed assembly; the inside of the reducer body 1 is provided with an oil storage chamber 4; the oil storage chamber 4 is ring-shaped and opened inside the reducer body 1; There are several oil outlet chambers 5 inside, and they are regularly arranged in a circular array; an oil hole 51 is opened between the oil storage chamber 4 and the oil outlet chamber 5; an oil baffle 6 is provided on the oil hole 51 The side wall of the oil baffle plate 6 is fixedly connected with a connecting rod 7; the end of the connecting rod 7 is fixedly connected with a first fixed block 9; the inside of the driving gear 3 is provided with a first sliding chamber 8; The first fixed block 9 is slidably connected insi...

Embodiment 2

[0036] see Figure 7 As shown in Comparative Example 1, as another embodiment of the present invention, the side wall of the sliding block 19 is fixed with a leak-proof gasket 30; 18 contacts; during work, when the sliding block 19 pumps air to the inside of the second sliding chamber 14, the leak-proof cushion layer 30 can make the sealing of the sliding block 19 stronger, thereby making the pumping effect of the sliding block 19 better.

[0037] Working principle, when working, when the reducer needs to be used, the rotating shaft 2 can be fixed inside the insertion rod groove 13, and then when the driving gear 3 rotates, the centrifugal force can drive the oil baffle plate 6 to the oil outlet chamber 5 direction, so that the lubricating oil inside the oil storage chamber 4 enters the inside of the oil outlet chamber 5, and then the lubricating oil flows out through the oil outlet hole 11, and the lubricating oil can lubricate between the driving gear 3 and the rest of the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com