Integrated butterfly valve

An integrated butterfly valve technology, applied in the field of hydraulic components, can solve the problems of hydraulic oil contamination, time-consuming and laborious emptying of the hydraulic oil tank, etc., so as to reduce the starting torque, reduce the risk of pollution, and improve the maintenance efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below according to the accompanying drawings and embodiments.

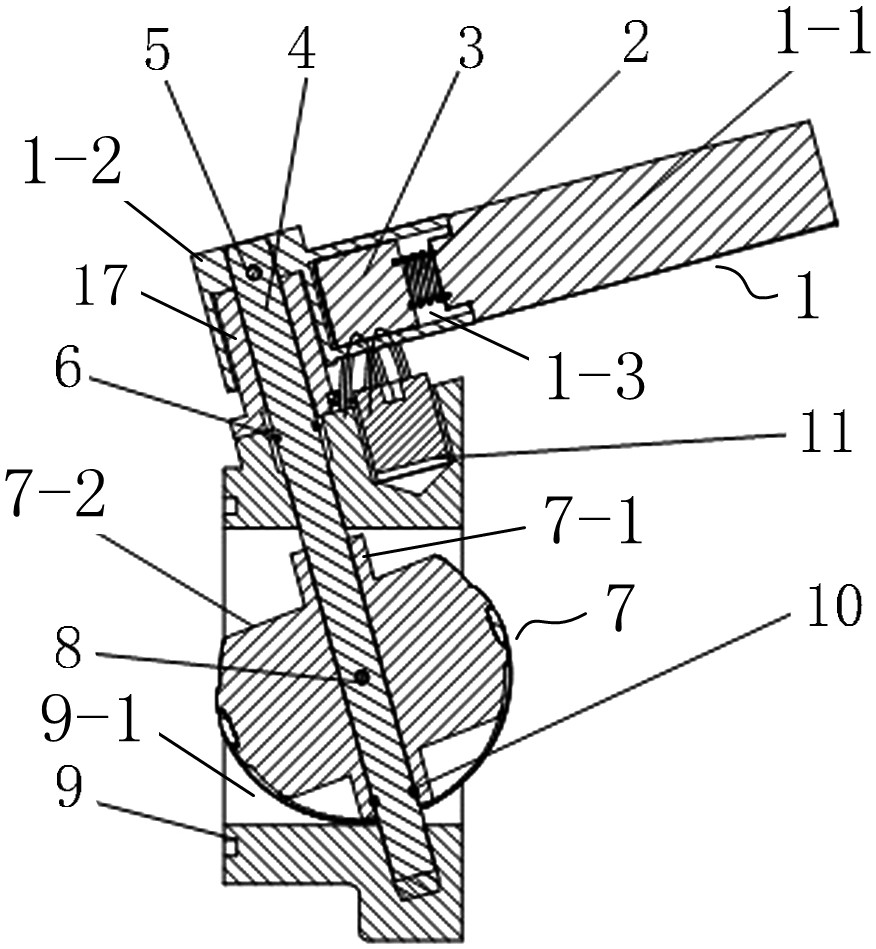

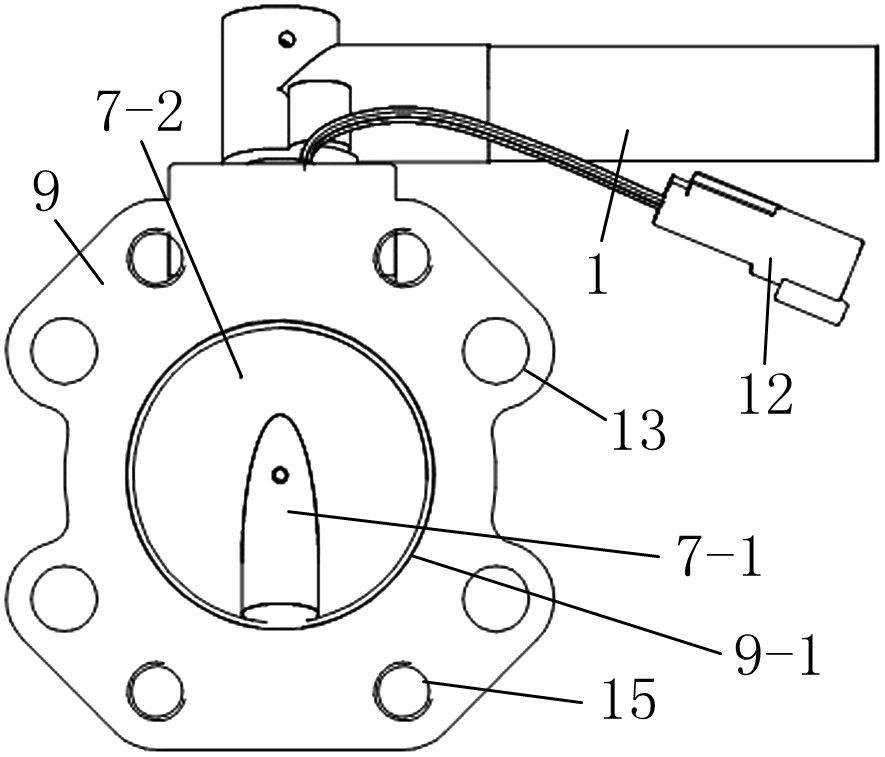

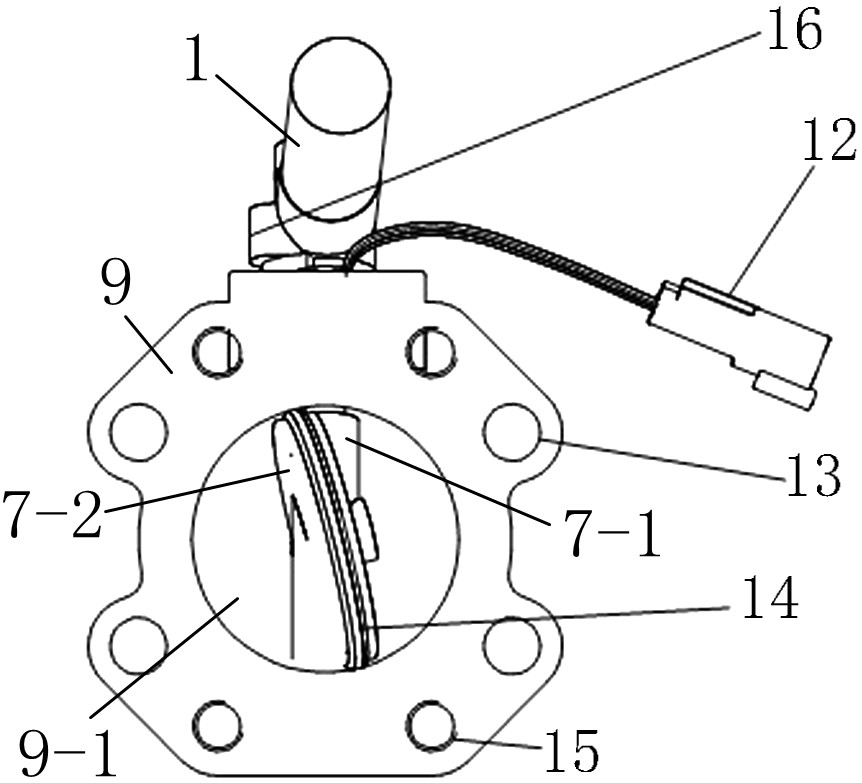

[0024] Such as Figure 1 to Figure 3 As shown, an integrated butterfly valve includes a valve body 9 , a valve plate 7 , a rotating shaft 4 and a handle 1 . Such as figure 1 As shown, the valve body 9 includes two end faces. When in use, the left end face of the valve body 9 is in contact with the tank mouth end face of the hydraulic oil tank. The valve body 9 is also provided with a sealing ring on the left end face to play a sealing role. Avoid oil leakage at the connection between the valve body 9 and the hydraulic oil tank, and the right end surface of the valve body 9 is connected with the hydraulic hose of the hydraulic system. Port 9-1; oil port 9-1 is used to connect the oil port of the hydraulic oil tank with the hydraulic hose, so that the hydraulic oil in the hydraulic oil tank can be sent into the hydraulic hose through the oil port 9-1 to provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com