Fabricated concrete greening construction enclosing wall

A prefabricated and walled technology, applied in the fields of fencing, sustainable waste treatment, solid waste management, etc., can solve the problems of fixed connection position, self-weight of prefabricated wall panels, etc., to achieve easy assembly and disassembly, convenient and reliable connection method, Realize the effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

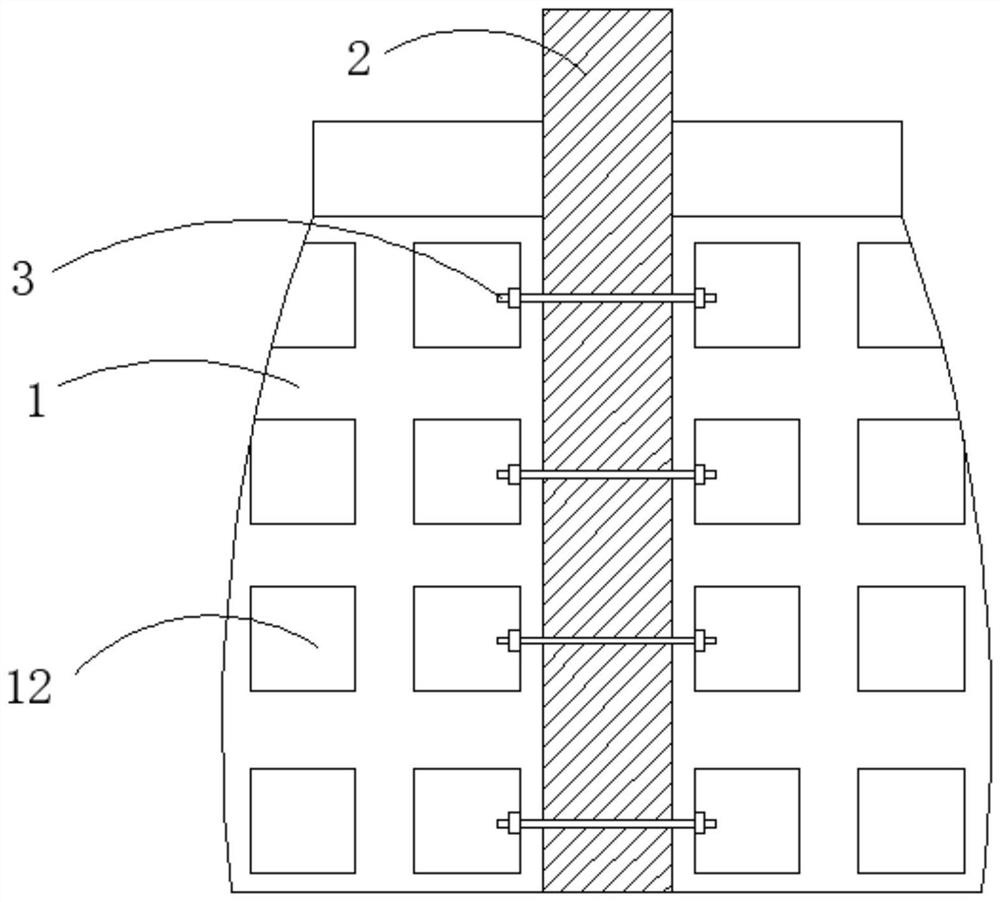

[0020] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

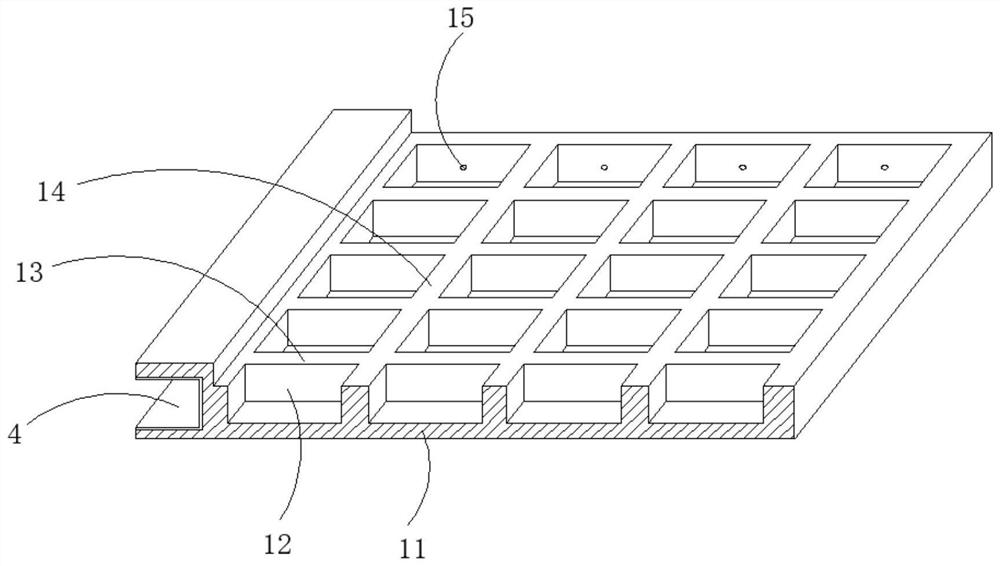

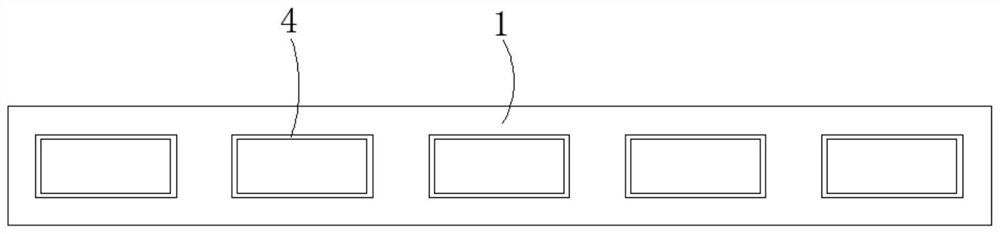

[0021] refer to Figure 1-2 , a prefabricated concrete greening construction fence, comprising a wall panel 1, the wall panel 1 includes a panel 11, a longitudinal rib beam 13 and a transverse rib beam 14, and the panel 11, the longitudinal rib beam 13 and the transverse rib beam 14 form a hollow The wall frame 12, the whole wall panel is light in weight and low in cost.

[0022] Since the general wall is located outdoors, the requirements for supporting strength are not high. Preferably, the panels 11, the longitudinal rib beams 14 and the transverse rib beams 13 are made of recycled aggregate concrete, and the recycled aggregate is applied to help realize construct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com