Suspension type overhead assembly building module with water storage counterweight structure

A suspension type and water bag technology, applied in buildings, water supply devices, sustainable buildings, etc., can solve problems affecting indoor comfort, water storage and water inconvenience, etc., to achieve convenient and stable suspension support, convenient water storage and water use, Flexible adjustment of water storage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

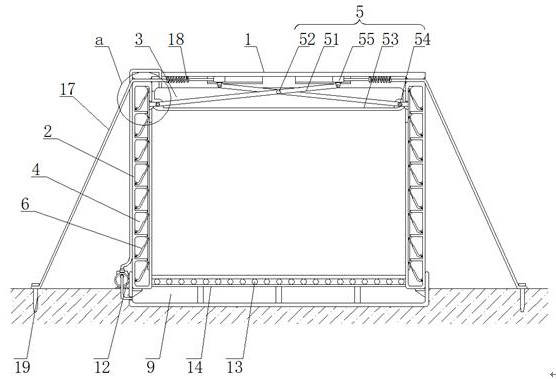

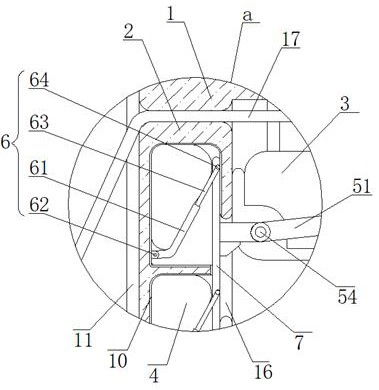

Embodiment 1

[0052] see Figure 1-4 and Figure 7 , the present invention provides a technical solution: a suspended overhead assembled building module with a water storage and counterweight structure, including an assembled top plate 1 and an assembled side plate 2, both of which are hollow structures inside, And the top water bag 3 and the movable water bag 4 are arranged inside the assembled top plate 1 and the assembled side plate 2 respectively. Scissor lifting structure, the interior of the assembled side plate 2 is evenly distributed with water storage ribs 6, and the water storage ribs 6 are installed obliquely inside the assembled side plate 2, and the movable water bag 4 is located between the assembled side plate 2 and the water storage rib 6, and the water storage ribs 6 form an inclined deflection structure inside the assembled side plate 2, and the water storage ribs 6 on one side of the assembled side plate 2 are synchronously hinged through the synchronous connecting rod 7...

Embodiment 2

[0057] see Figure 5-7 , the present invention provides a technical solution: a suspended overhead assembled building module with a water storage and counterweight structure, including an assembled top plate 1 and an assembled side plate 2, both of which are hollow structures inside, And the top water bag 3 and the movable water bag 4 are arranged inside the assembled top plate 1 and the assembled side plate 2 respectively. Scissor lifting structure, the interior of the assembled side plate 2 is evenly distributed with water storage ribs 6, and the water storage ribs 6 are installed obliquely inside the assembled side plate 2, and the movable water bag 4 is located between the assembled side plate 2 and the water storage rib 6, and the water storage ribs 6 form an inclined deflection structure inside the assembled side plate 2, and the water storage ribs 6 on one side of the assembled side plate 2 are synchronously hinged through the synchronous connecting rod 7, and the synch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com