Silt remover pipe head for hydraulic engineering design

A water conservancy project and desilting machine technology, which is applied in the direction of earth mover/shovel, mechanically driven excavator/dredger, construction, etc., can solve the problem of blocking the feed inlet, so as to avoid blockage and improve passability , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

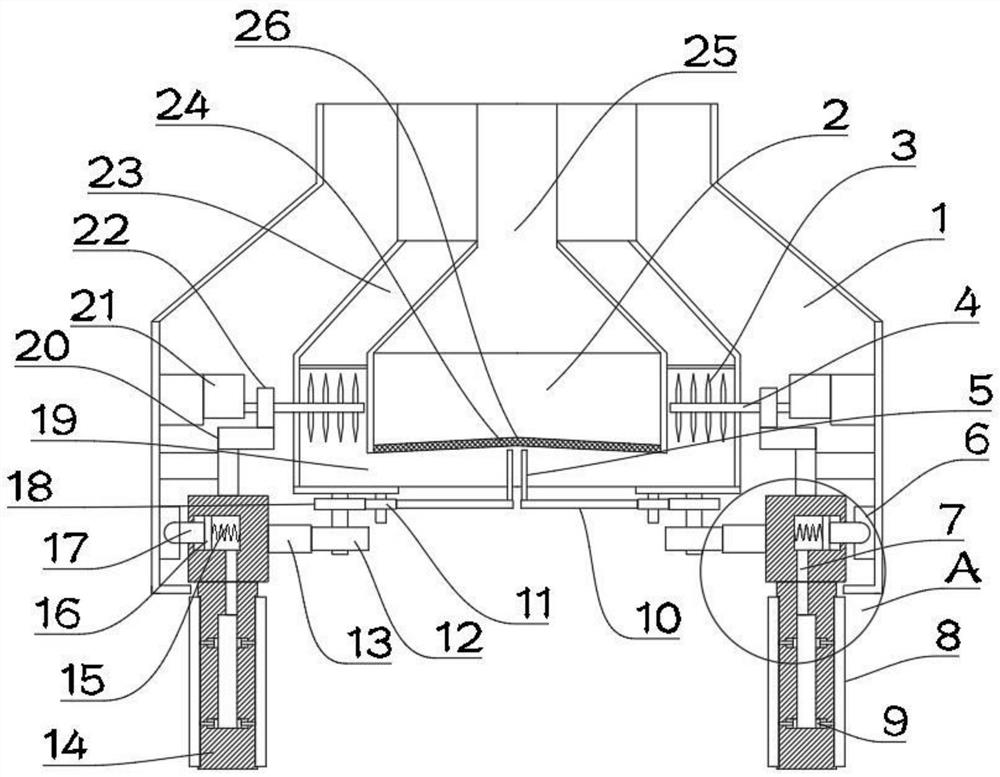

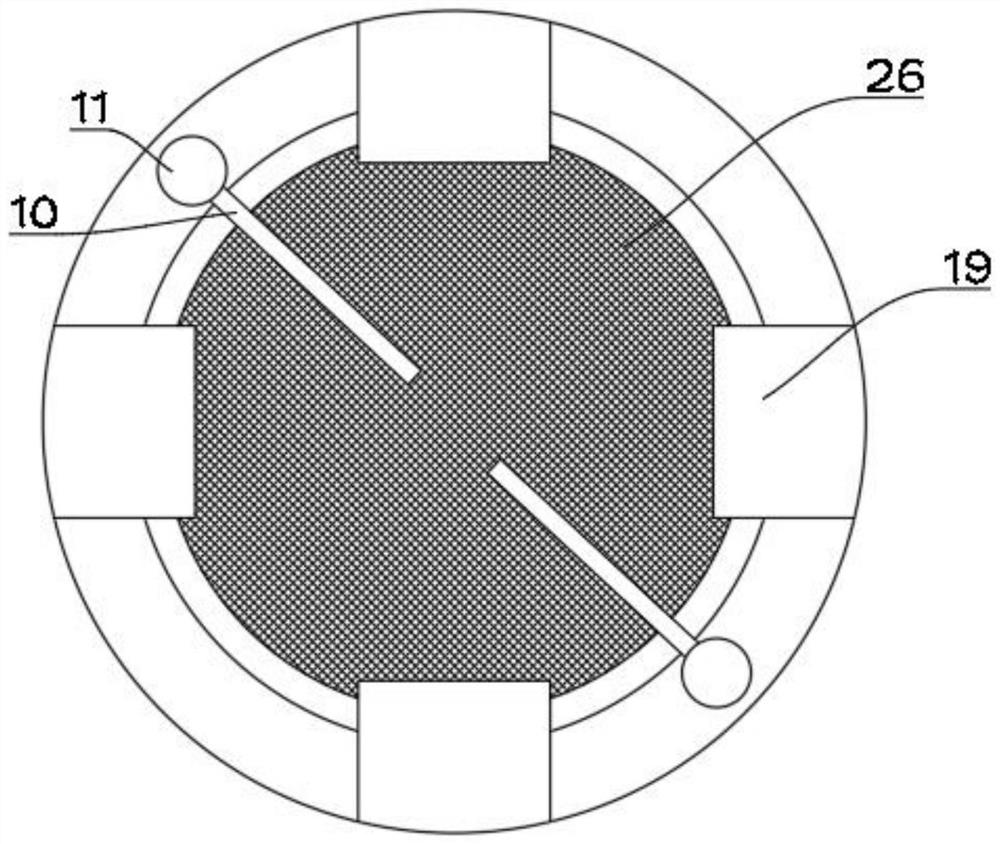

[0031] see Figure 1 ~ Figure 3 , in Embodiment 1 of the present invention, a structural diagram of a pipe head of a dredging machine for water conservancy engineering design provided by the embodiment of the present invention, including: a support shell 1; a suction head for absorbing silt is provided inside the support shell 1 2. The middle position of the bottom of the absorption head 2 is provided with a main adsorption port 24 for absorbing silt, and the outer array of the main adsorption port 24 is provided with a plurality of auxiliary inlets 19, and the auxiliary inlets 19 are used for absorbing aquatic plants;

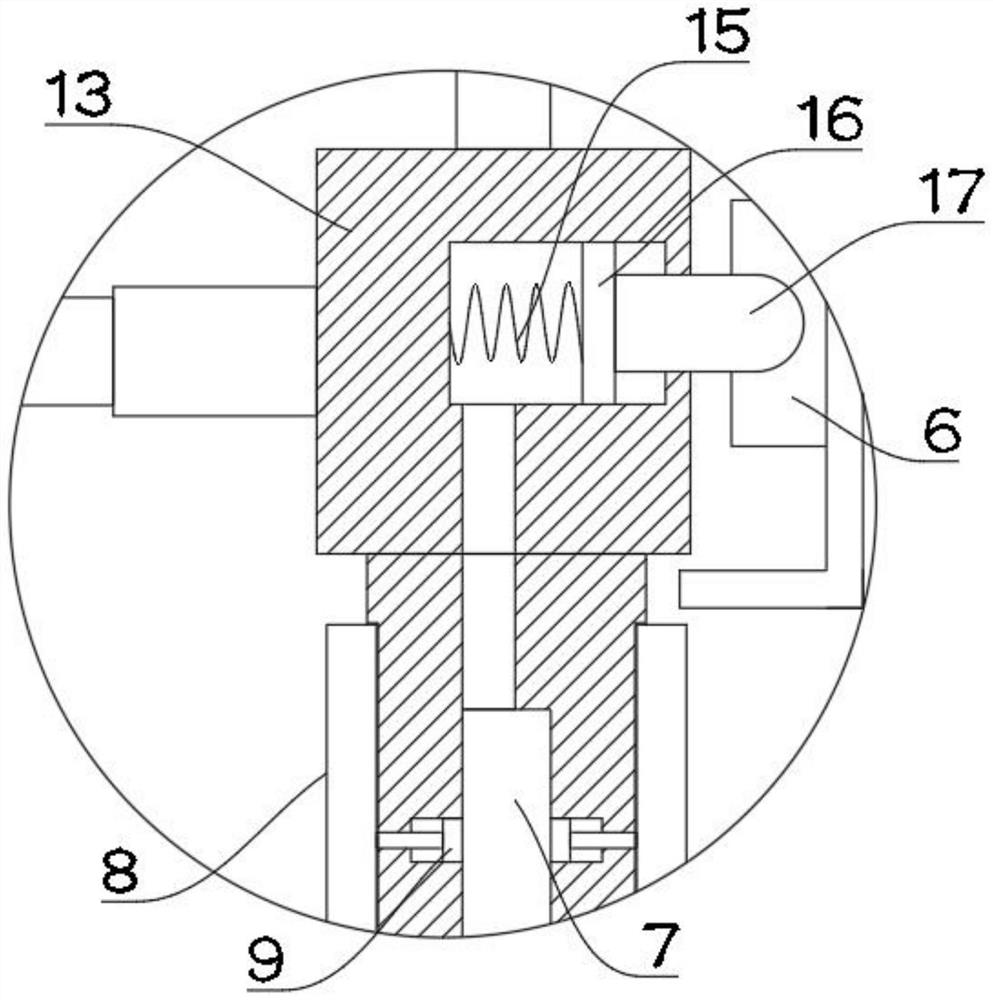

[0032] A plurality of installation rods 14 arranged on the outside of the absorption head 2 in a circular array, and a plurality of crushing knives 8 are arranged in an array on the installation rod 14; the installation rods 14 are installed on the second gear ring 13, and the second The gear ring 13 is rotatably arranged inside the supporting shell 1; a plura...

Embodiment 2

[0037] see Figure 1 ~ Figure 3The main difference between this embodiment 2 and embodiment 1 is that in order to be able to treat aquatic plants and prevent clogging, the auxiliary adsorption channel 23 is provided with a crushing assembly. The crushing assembly includes a crushing shaft 4 rotatably mounted on the absorption head 2 , the surface of the crushing shaft 4 is provided with a plurality of crushing teeth 3 in an array, and the crushing teeth 3 are arranged inside the auxiliary adsorption flow channel 23 . In this way, the rotation of the crushing shaft 4 drives the rotation of the absorption head 2, thereby enabling the crushing teeth 3 to crush aquatic plants.

[0038] The suction head 2 is connected with a negative pressure pump for providing negative pressure to the main adsorption channel 25 and the auxiliary adsorption channel 23 .

[0039] Such as figure 1 , 2 As shown, as a preferred embodiment of the present invention, in order to drive the second gear r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com