Composite microbial agent and application thereof in biogas residue high-temperature aerobic composting

A technology of compound microbial inoculants and bacilli, applied in the field of environmental microorganisms, can solve the problems of low composting temperature, long composting cycle, incomplete decomposing of organic matter, etc., so as to improve the decomposing degree of materials and the quality of organic fertilizer, rapidly decompose and shorten the composting period. effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The present invention also provides a preparation method of the liquid composite microbial bacterial agent, the preparation method comprising the following steps: making Lithuanian Geobacillus lituanicus G6-1, Pitt Acinetobacter Acinetobacterpittii AP-16, Pantoea sp.BK - mixing PP311 and fermented broth of Geobacillus kaustophilus FWGK-JYJ1 to obtain the liquid composite microbial agent.

[0032] In one embodiment, the Lithuanian Geobacillus lituanicus G6-1, Pitt Acinetobacter Acinetobacter pittii AP-16, Pantoea sp.BK-PP311 and thermophilic Geobacillus kaustophilus FWGK-JYJ1 The fermentation broths were all prepared by the following method: Lithuanian Geobacillus lituanicus G6-1, Pitt Acinetobacter pittii AP-16, Pantoea sp.BK-PP311 and thermophilic Geobacillus kaustophilus FWGK-JYJ1 The pure strains are inoculated in the liquid medium for cultivation, and after the cultivation is completed, it is the fermentation liquid of each strain.

[0033] In one embodiment, after...

Embodiment 1

[0080] Embodiment 1: the preparation of composite microbial bacterial agent

[0081] Preparation of liquid composite microbial agent: Geobacillus lituanicus G6-1, Acinetobacter pittii AP-16, Pantoea sp.BK-PP311, Geobacillus kaustophilus FWGK-JYJ1 The pure strains of the strains were inoculated into 5mL CYS liquid medium, and cultured at 50°C and 180r / min for 12-16h; the inoculation amount of 1% by volume was inserted into the same CYS liquid medium for gradual After expanding the culture, after the cultivation under the same conditions, the fermentation broths of the four strains were obtained respectively; the fermentation broths of the four strains were evenly mixed according to the volume ratio of 1:1:1:1 to obtain liquid composite microorganisms Bacteria.

[0082] The composition of CYS liquid medium is: peptone 3g / L, yeast extract 2g / L, soluble starch 1g / L, NaCl 3g / L, MgCl 2 0.125g / L, CaCl 2 0.5g / L, FeSO 4 ·7H 2 O 0.01g / L, trace element solution (Na 2 MoO 4 12g / ...

Embodiment 2

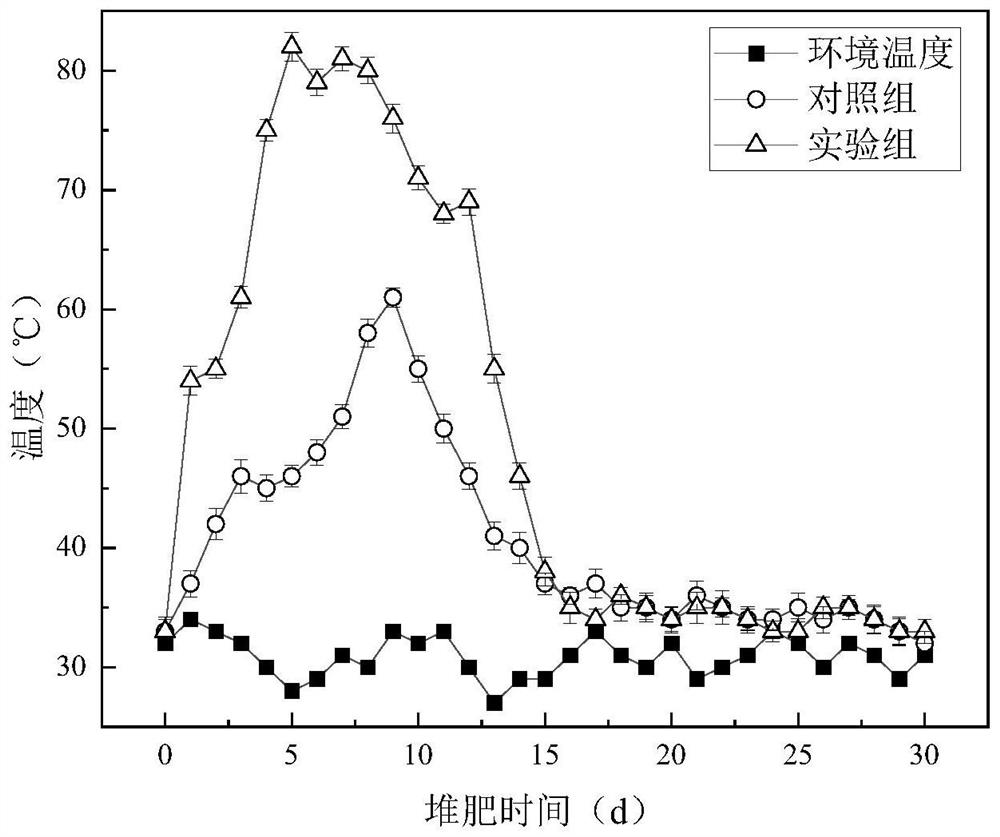

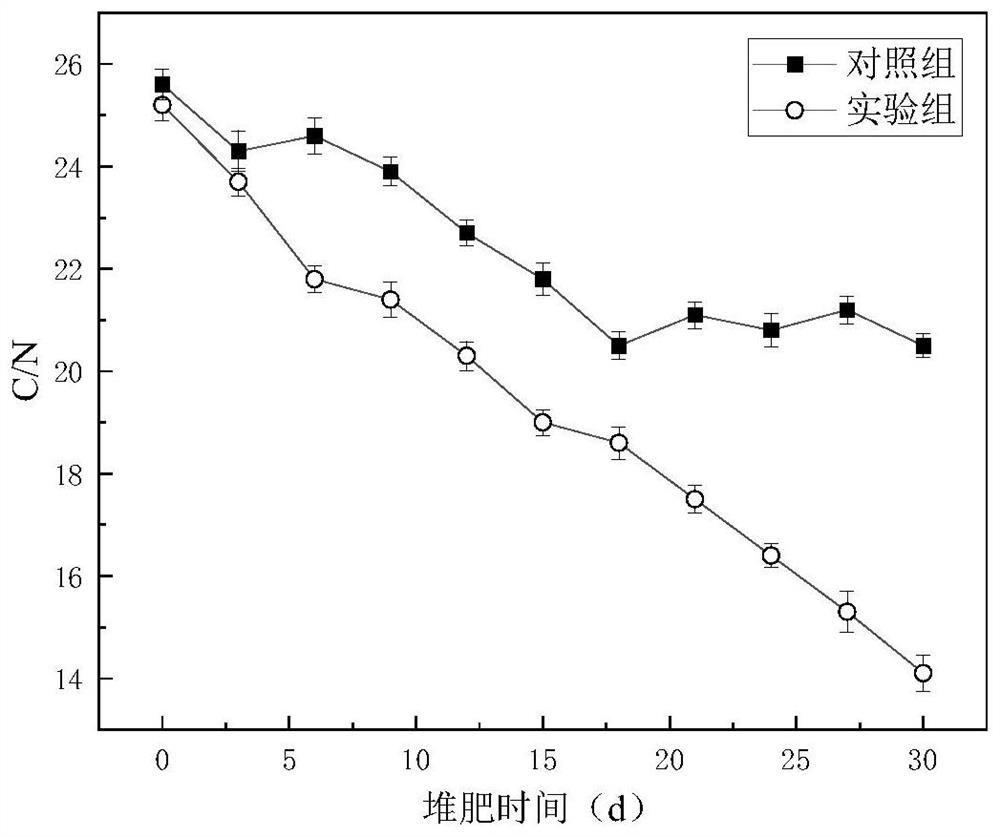

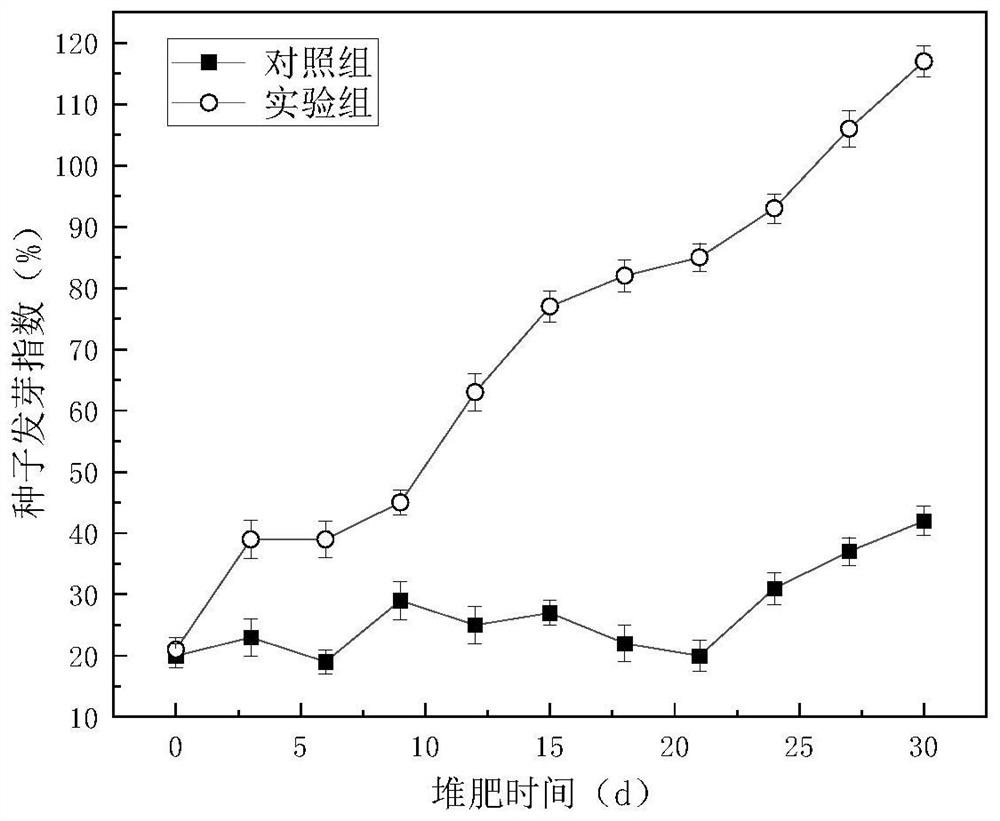

[0084] Example 2: Effect of compound microbial agent on high-temperature aerobic composting of biogas residue and rice straw

[0085] Take 10kg of biogas residue from anaerobic fermentation of kitchen waste and 3kg of rice straw, put them in aerobic fermentation equipment with good thermal insulation performance, and mix them evenly to obtain a total of 13kg of mixed materials. Add 65g of solid composite microbial bacterial agents according to the mass ratio of 0.5%. Stir well. At this time, the initial C / N of the material is 26, the initial moisture content of the material is adjusted to 60%, and the initial pH value is 7.0. Then start the aerobic fermentation of the material, with uninterrupted ventilation during the process, and stir the material once a day. At the same time, set up a control group without adding compound microbial agents, and use the same materials and conditions for aerobic composting. At the same time every day, the compost temperature was measured and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com