Accurate cutting device for building water-absorbing bricks

A technology for cutting off devices and water-absorbing bricks, which is applied to work accessories, manufacturing tools, stone processing tools, etc., can solve problems such as inability to cut off water-absorbing bricks, achieve precise cutting, and speed up work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

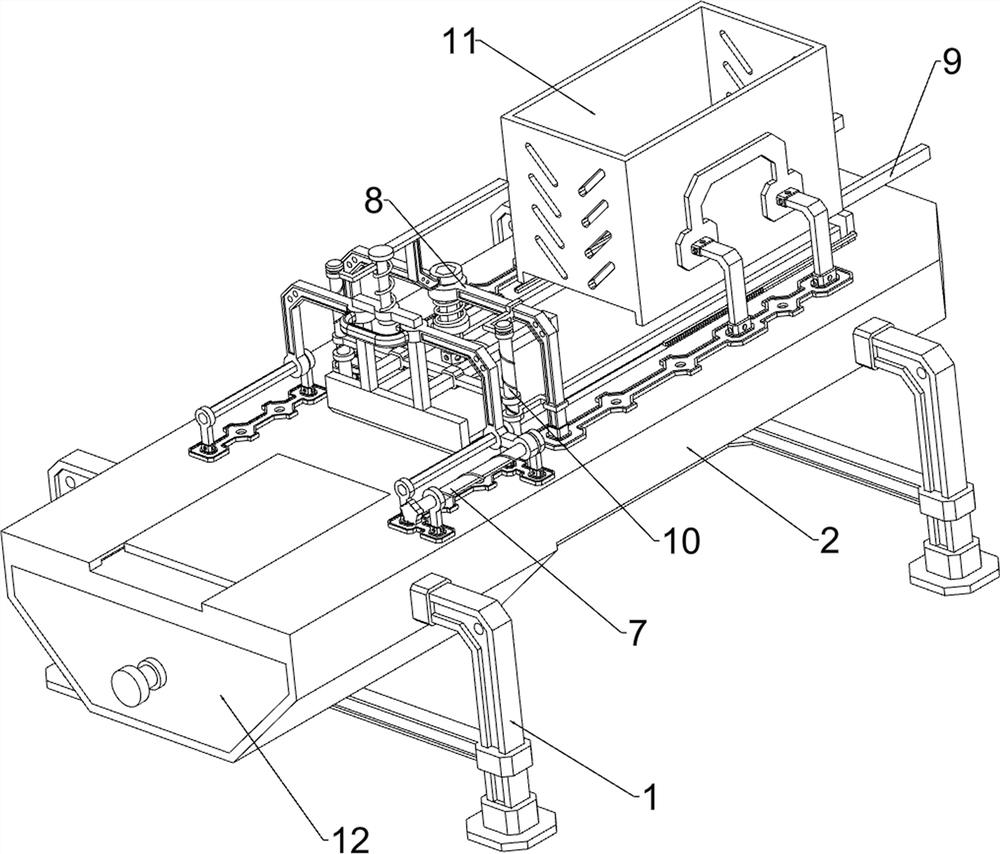

[0034] A precise cutting device for building water-absorbing bricks, please check Figure 1-6 , including a support frame 1, a fixed frame 2, a guide rod 3, a first sliding frame 4, a second sliding frame 5, a cutting knife 6, a toggle lever 61, an adjustment mechanism 7 and a fixing mechanism 8, and the bottom of the support frame 1 is provided There is an anti-slip pad, which is convenient for the support frame 1 to be placed on the ground stably. The top of the support frame 1 is connected to the fixed frame 2 by welding, and the front side of the top of the fixed frame 2 is connected to two guide rods 3 by welding. The two guide rods 3 are Left and right symmetrical arrangement, the first sliding frame 4 is slidably connected between the two guide rods 3, the top of the first sliding frame 4 slides through the second sliding frame 5, and the bottom of the second sliding frame 5 is connected with a cutting knife 6. Two toggling levers 61 are connected to the bottom rear sid...

specific Embodiment approach 2

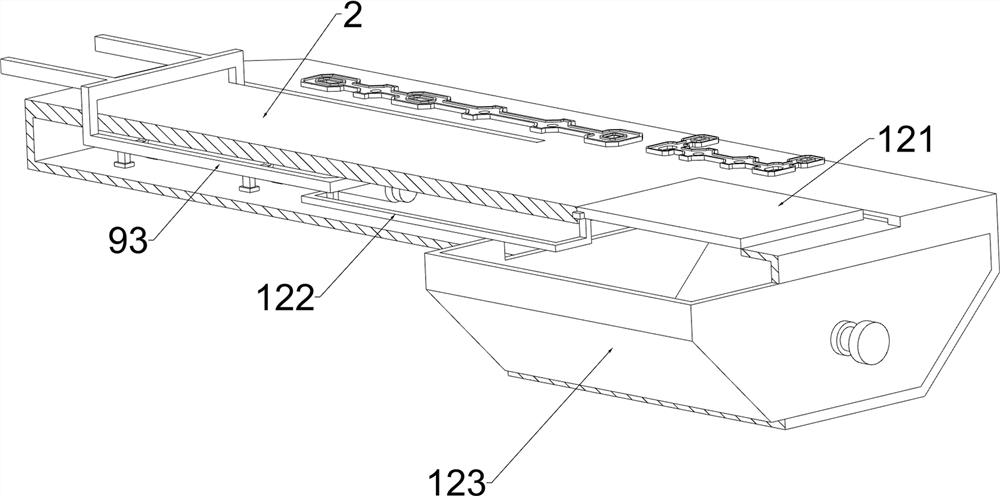

[0038] On the basis of specific implementation mode 1, please check figure 1 , figure 2 , Figure 7 and Figure 8 , also includes pusher mechanism 9, and pusher mechanism 9 includes second fixed mount 91, cylinder 92 and pusher frame 93, and the rear side of fixed frame 2 inside is connected with two second fixed mounts 91 by welding, two The second fixed frame 91 is symmetrically arranged front and back, and a cylinder 92 is installed between the two second fixed frames 91. The telescopic rod of the cylinder 92 is connected with a pusher frame 93, and the pusher frame 93 slides through the top of the fixed frame 2. .

[0039] First, place the water-absorbing brick in front of the pusher frame 93, then pull the cutting knife 6 upwards through the second sliding frame 5, then pull up the diamond-shaped column 82 and the clamping block 83 through the lower pressing rod 84, and then open the air cylinder 92, the telescopic rod of the cylinder 92 drives the pusher frame 93 to...

specific Embodiment approach 3

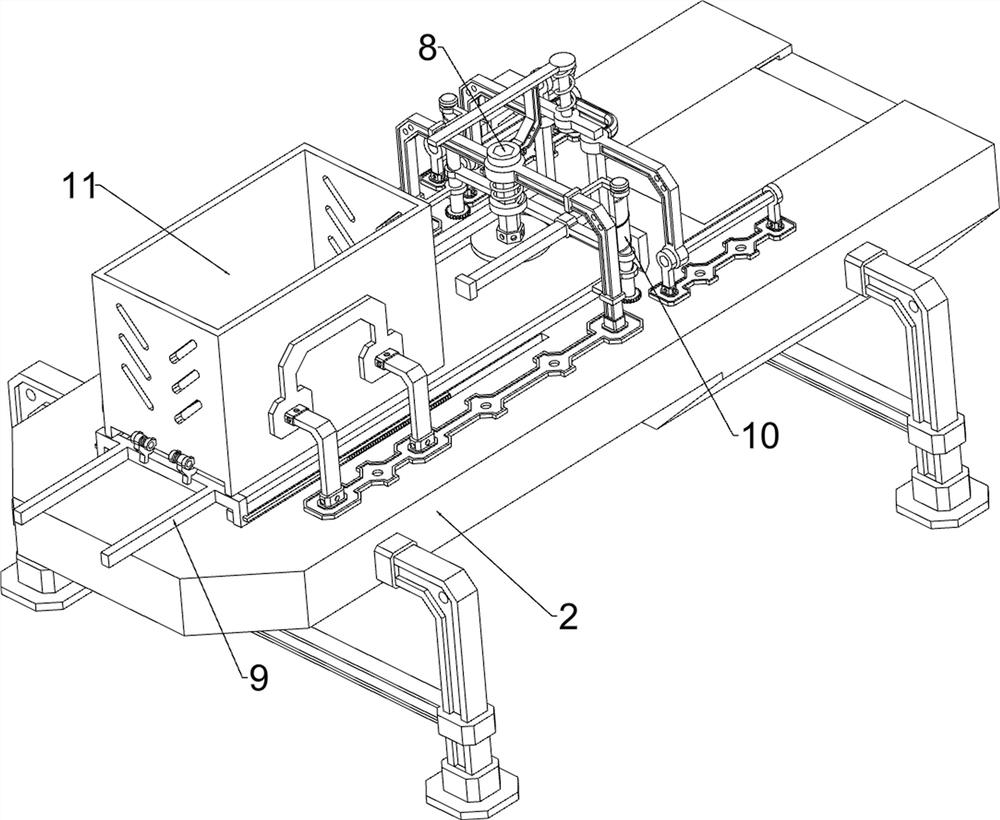

[0040] On the basis of the specific implementation mode 2, please check figure 1 , figure 2 , Figure 5 , Figure 6 , Figure 9 and Figure 10 , also includes a pressing mechanism 10, and the pressing mechanism 10 includes a third fixed frame 101, a second threaded rod 102, a slider 103, a spur gear 104, a rack 105, a first spring 106, a second spring 107, a dial The moving block 108 and the sliding rod 109, the top of the second sliding frame 5 slides through the sliding rod 109, the bottom of the left and right sides of the first fixed frame 81 and the tops of the left and right sides are connected with the third fixed frame 101 by welding, Second threaded rods 102 are rotatably penetrated between the two third fixed frames 101 on the left side and the two third fixed frames 101 on the right side, and spur gears 104 are connected to the bottoms of the two second threaded rods 102 . Between the middle parts of the two second threaded rods 102, a slide block 103 is threa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com